Novel composite template, manufacturing method and board manufactured through composite template

A composite formwork and manufacturing method technology, which is applied in the fields of furniture, vehicles and ships, and construction, can solve the problems of reducing weather resistance, service life, and different physical properties, and achieve the effects of prolonging service life, optimizing cost performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

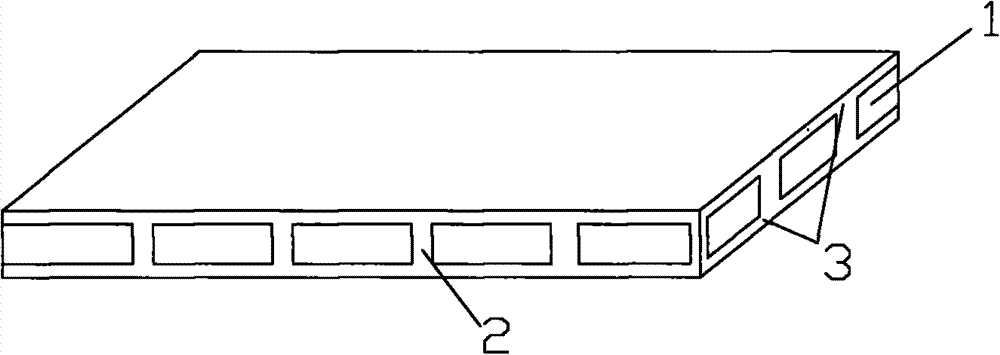

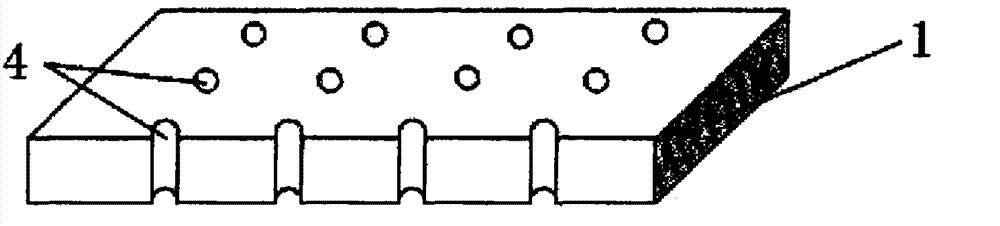

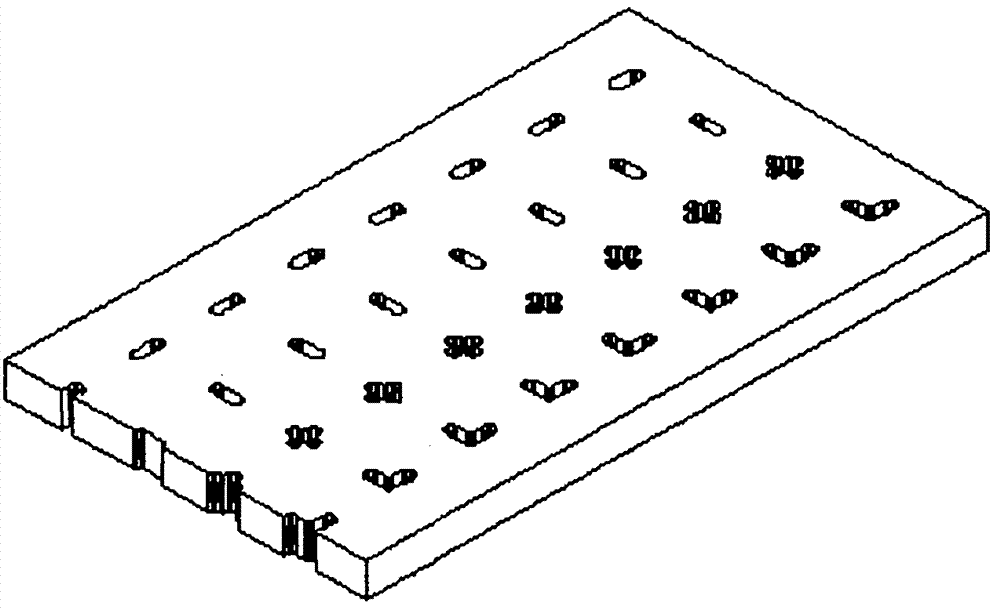

[0046] Embodiment 1: A new type of composite building formwork

[0047] A new type of composite building formwork, such as figure 1 , 2 As shown, it includes a substrate 1, a rubber-plastic connecting column 2 and a rubber-plastic coating layer 3. A cylindrical through-hole 4 is opened on the substrate 1, and the rubber-plastic connecting column 2 runs through the through-hole 4 of the substrate 1. The rubber-plastic coating layer Layer 3 is coated on the upper and lower surfaces of the substrate 1 and tightly adhered to the substrate 1, and forms an integrated structure with the rubber-plastic connecting column 2; the diameter of the rubber-plastic connecting column 2 is 6 mm, and the distance between two adjacent rubber-plastic connecting columns 2 is 50mm, the thickness of the rubber-plastic cladding layer 3 is 1mm, and the total thickness of the building formwork is 10mm. In this embodiment, the substrate 1 is made of wood plywood.

[0048] By the manufacture method of...

Embodiment 2

[0059] Example 2: An energy-saving, heat-preserving and flame-retardant wall panel

[0060] like figure 1 , 2 As shown, it includes a substrate 1, a rubber-plastic connecting column 2 and a rubber-plastic coating layer 3. An elliptical column through hole 4 is opened on the substrate 1, and the rubber-plastic connecting column 2 runs through the through hole 4 of the substrate 1. The rubber-plastic coating layer The layer 3 is coated on the upper and lower surfaces of the substrate 1 and closely adheres to the substrate 1, and forms an integral structure with the rubber and plastic column 2; specifically, the substrate 1 is made of phenolic foam insulation board. The through hole is a cross-shaped through hole with a width of 8 mm. The distance between two adjacent rubber and plastic columns 2 is 100mm. The thickness of the rubber and plastic covering layer 3 is 6mm. The thickness of the composite sheet is 100mm. The rubber and plastic slurry is made of micro-foamed CPVC...

Embodiment 3

[0063] Example 3: A New Type of Composite Lightweight Separator

[0064] like figure 1 , 2 As shown, it includes a substrate 1, a rubber and plastic connecting column 2 and a rubber and plastic coating layer 3. A cylindrical through hole 4 is opened on the substrate 1, and the rubber and plastic connecting column 2 runs through the through hole 4 of the substrate 1. The rubber and plastic coating layer 3 The upper and lower surfaces of the base plate 1 are tightly attached to the base plate 1, and form an integrated structure with the rubber and plastic column 2; specifically, the diameter of the rubber and plastic connecting column 2 is 8mm, and the distance between the centers of the ellipse is 10mm. The lateral distance of the rubber and plastic column 2 is 10mm, the longitudinal distance is 10mm, the thickness of the rubber and plastic cladding layer 3 is 6mm, and the total thickness of the composite plate is 26mm. In this embodiment, the substrate 1 is made of a moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com