Zipper copper buckle point riveting device and method and automatic zipper head assembling equipment

A technology of copper buttons and zippers, which is applied in the field of clothing production, can solve the problems that the copper buttons cannot be fully installed, the copper buttons are difficult to assemble, and the riveting precision of the copper buttons is not high, so as to achieve accurate and controllable feeding process, good forming effect, Assembling efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

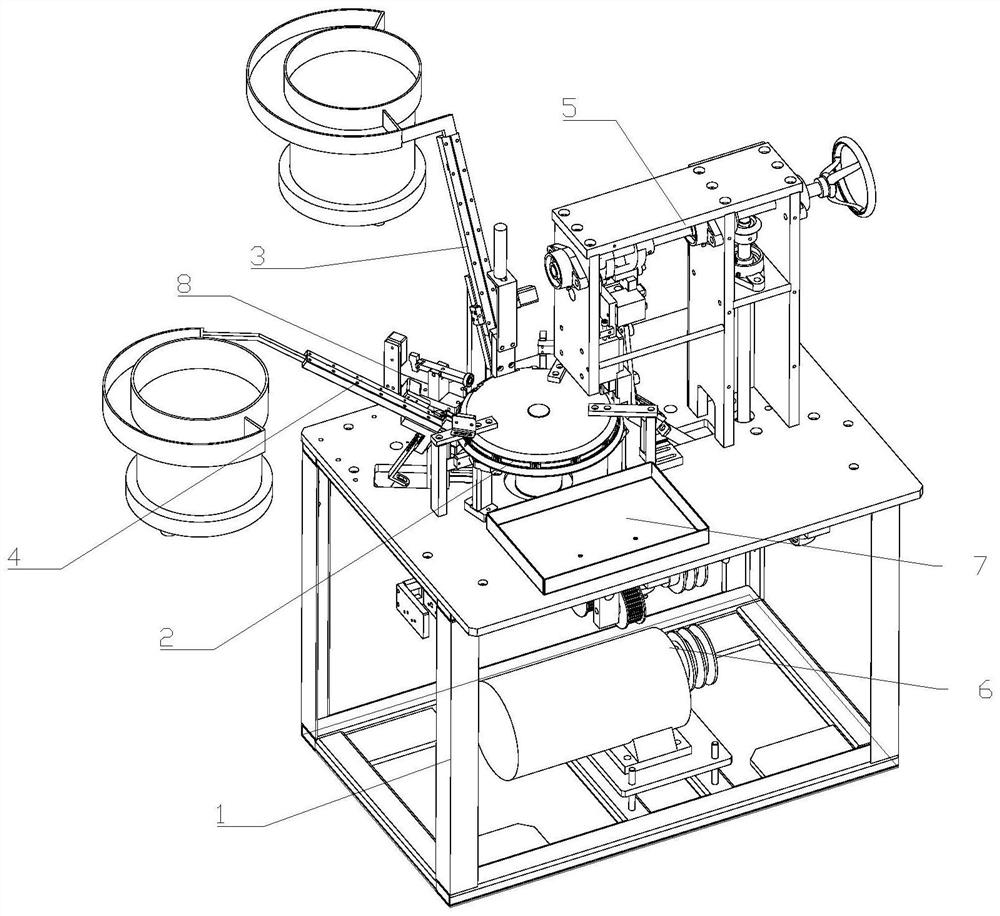

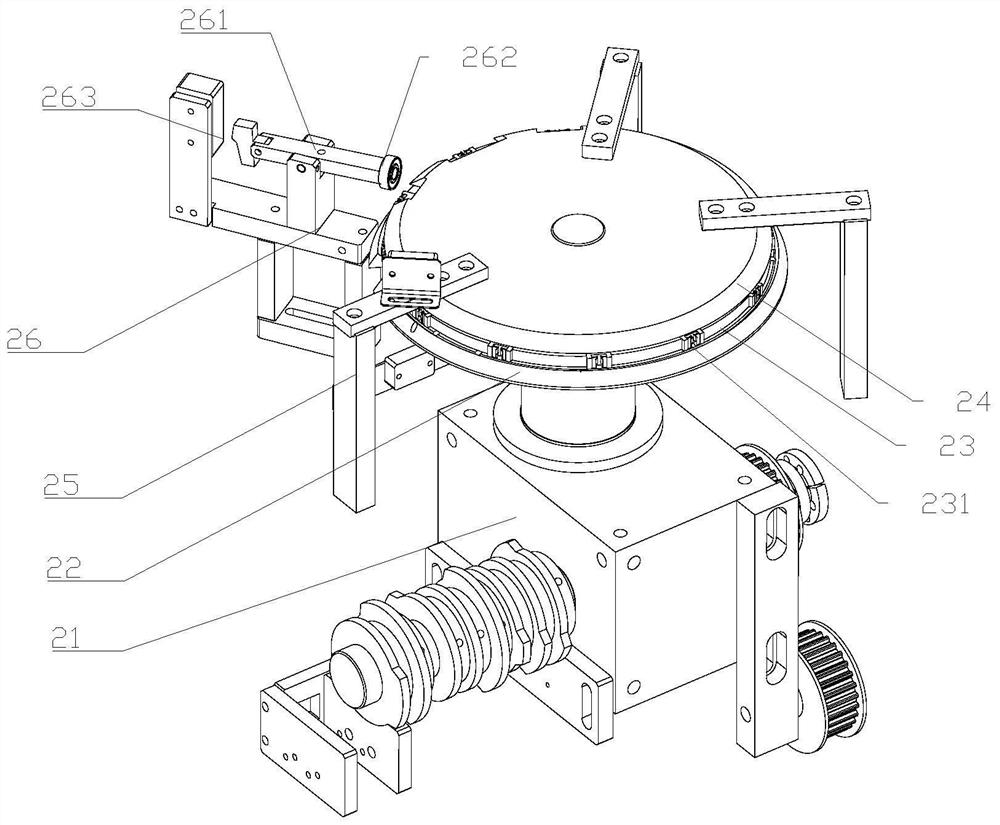

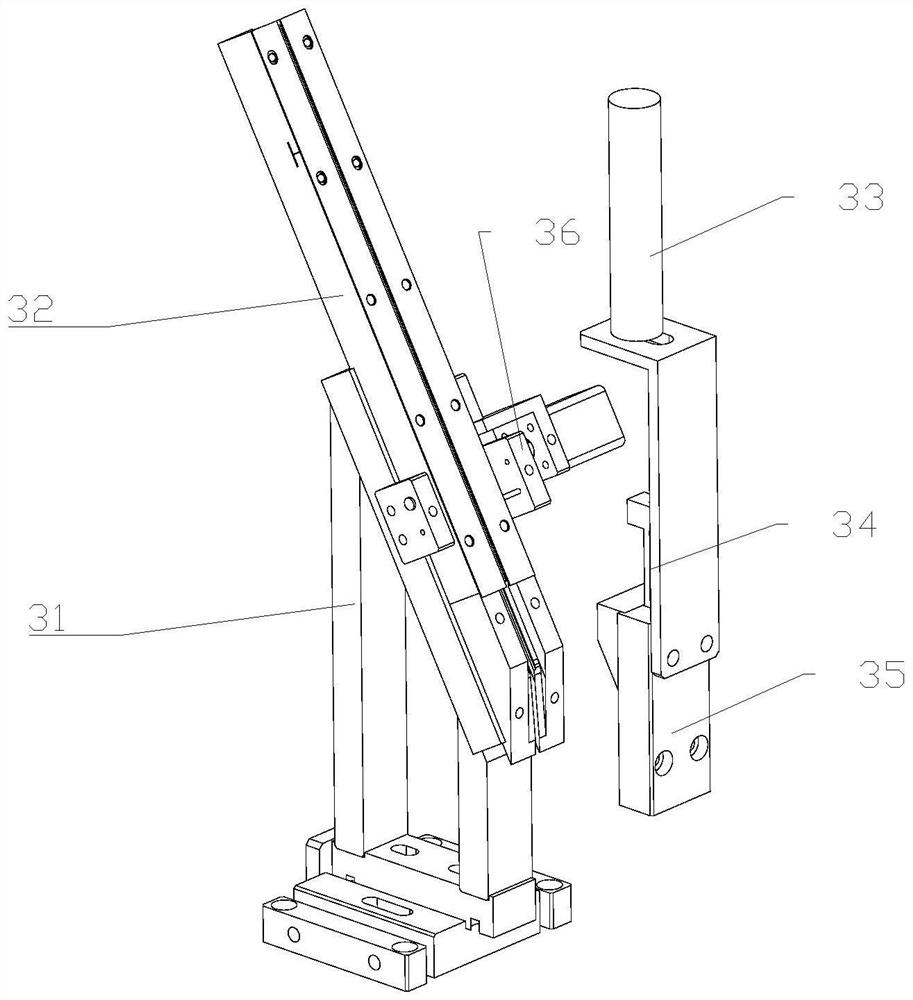

[0033] Such as figure 1 As shown, a zipper slider automatic assembly equipment includes a frame 1, a tray device 2, a zipper seat feeding device 3, a copper buckle feeding device 4, a zipper copper buckle point riveting device 5 and a power unit 6, and the tray loading device 2. Installed on the frame 1, the disc carrier device 2 is in a rotating mode. Along the processing direction, the zipper seat feeding device 3, the copper buckle feeding device 4 and the zipper copper buckle point riveting device 5 are sequentially arranged on the carrier device 2. One week, the frame 1 is also provided with a material tray 7, the material tray is located between the copper buckle feeding device 4 and the zipper copper buckle point riveting device 5, the power unit 6 is installed on the frame 1, and the power output end of the power unit 6 It is connected with the carrier device 2 and the zipper copper buckle point riveting device 5; the frame 1 is also provided with a zipper seat detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com