Thermal conduction liquid used by groove-type solar photo-thermal power generation system

A trough-type solar energy and heat transfer fluid technology, applied in the field of energy chemistry, can solve problems such as undiscovered, easy to solidify, and expensive, and achieve good thermal stability, long-term low-temperature anti-condensation, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

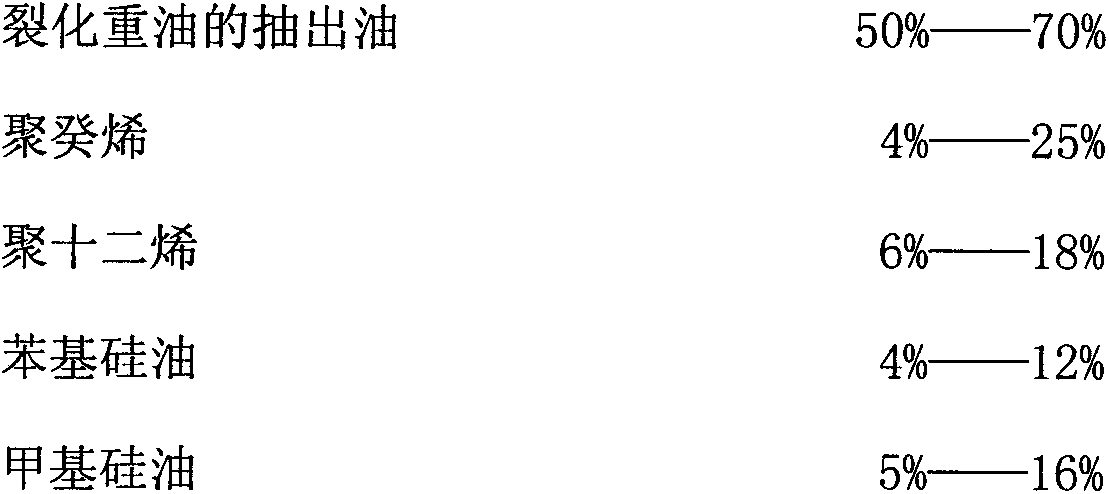

[0013] A kind of heat conduction fluid used for trough solar thermal power generation system, its composition and weight percentage are as follows:

[0014]

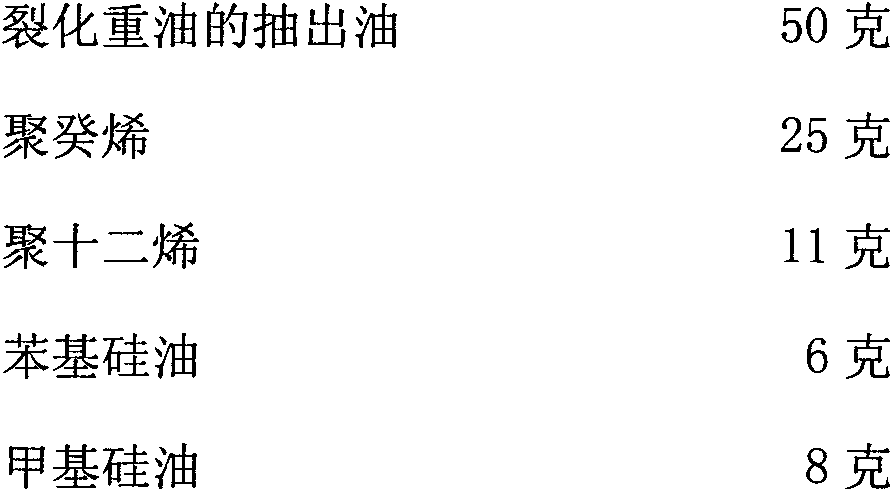

[0015] A kind of heat transfer liquid used in the trough solar thermal power generation system of the present invention, its preparation method is: take 25 grams of polydecene, 12 grams of polydodecene, 5 grams of phenyl silicone oil, 8 grams of methyl silicone oil and heat to 95 ℃, respectively added to the reaction kettle and stirred evenly, and then added 50 grams of extracted oil of cracked heavy oil that had been heated to 90 ℃, and continued to stir for 5 minutes to complete. The finished product of the invention is a golden yellow transparent liquid with good fluidity.

Embodiment 2

[0017] A kind of heat conduction fluid used for trough solar thermal power generation system, its composition and weight percentage are as follows:

[0018]

[0019] The weight percentages of the above components in the second embodiment are different from those in the first embodiment, except that the preparation method is consistent with that described in the first embodiment.

Embodiment 3

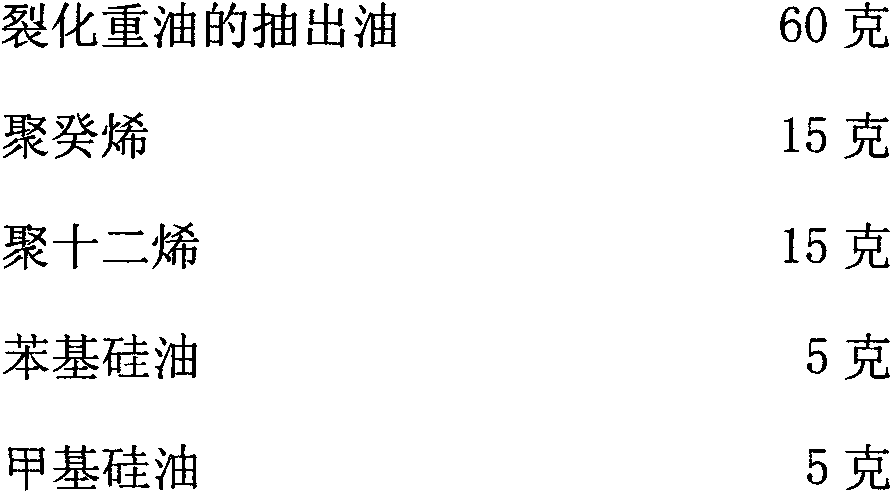

[0021] A kind of heat conduction fluid used for trough solar thermal power generation system, its composition and weight percentage are as follows:

[0022]

[0023] The weight percentages of the above components in the third embodiment are different from those in the first embodiment, except that the preparation method is consistent with that described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com