Monitoring system used for multistage biomass fermentation reaction system and monitoring method thereof

A technology of biomass fermentation and monitoring system, which is applied to the monitoring system and its monitoring field for multi-stage biomass fermentation reaction system, and can solve problems such as optimizing the fermentation system and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

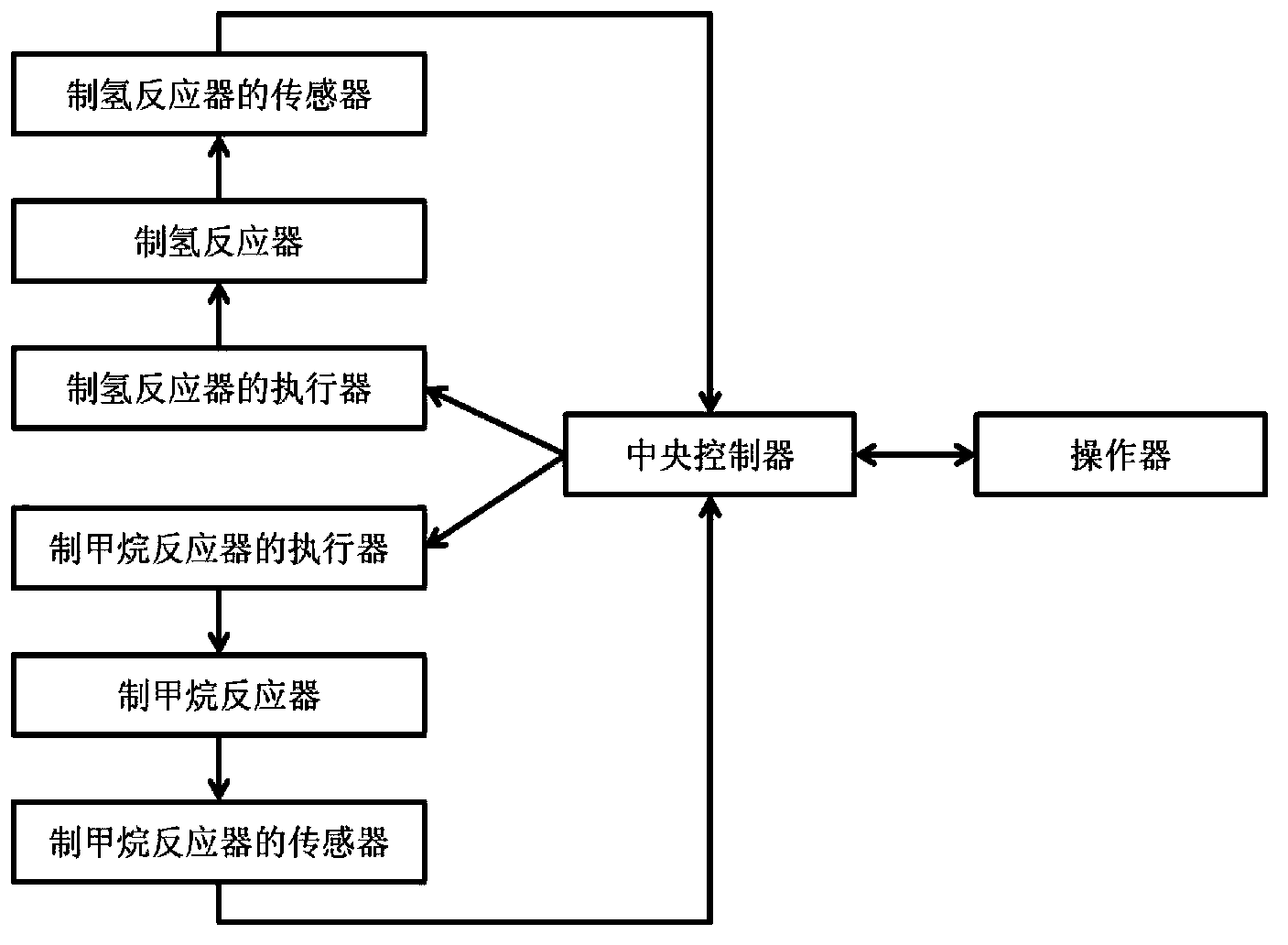

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

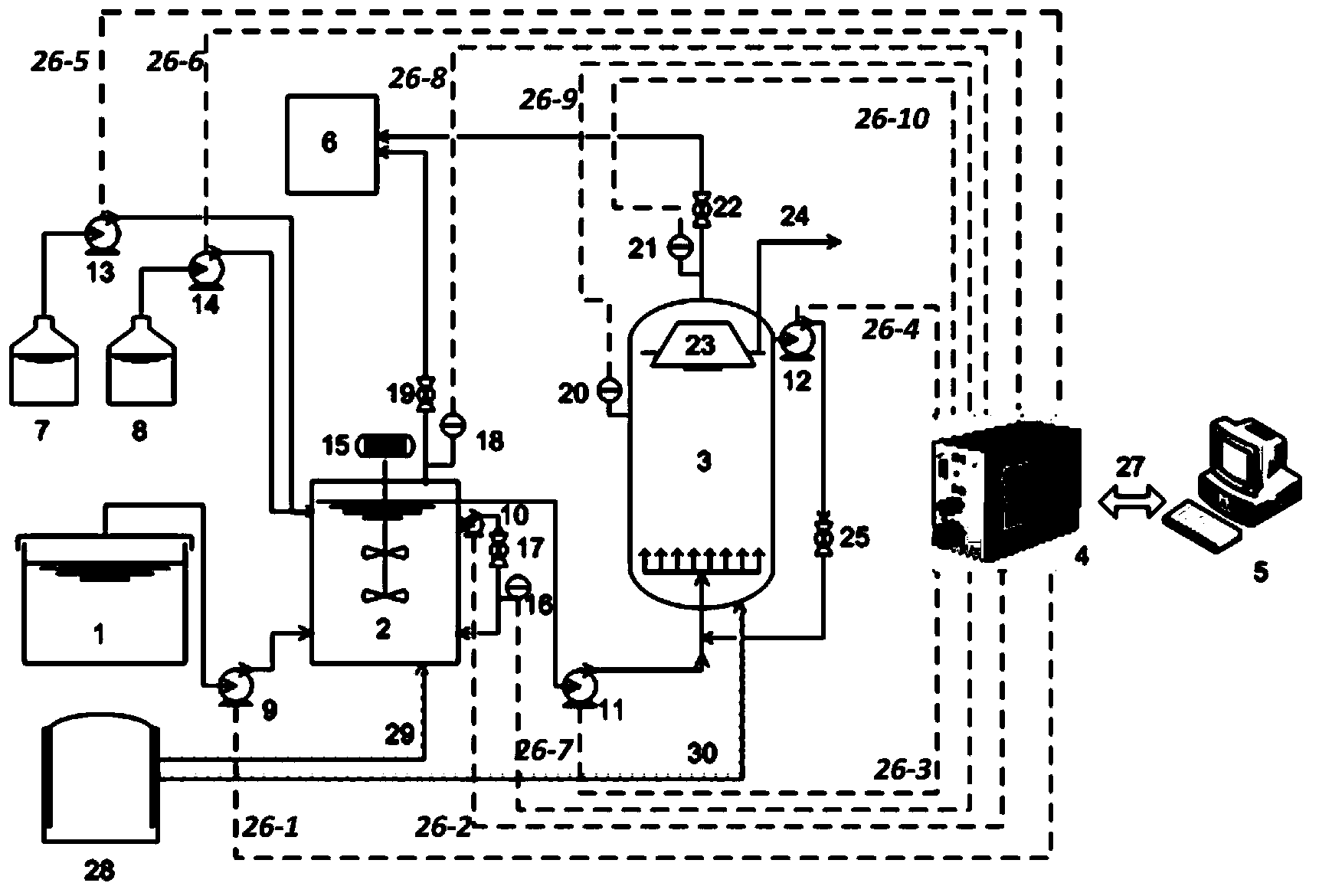

[0070] Example 1: Using corn stalks to produce hydrogen / methane mixed hydrogen with a mixing ratio (volume ratio) of 1:2

[0071] In this example, corn stalks produced in Songyuan City, Jilin Province were selected as the biomass raw material for the preparation of mixed hydrogen alkanes. The quantitative analysis of its components (weight %) is shown in Table 1 below.

[0072] Table 1

[0073] Cellulose

Ash

45

35

13

5

2

[0074] Cut the above corn stalks into small sections with a length of 5 cm, perform physical pretreatment by steam explosion, and send the pretreated corn stalks into figure 1 in the system shown. Among them, the hydrogen production reactor 2 is a medium temperature continuous flow stirred reactor (CSTR), and the methane production reactor 3 is a medium temperature upflow anaerobic sludge bed (UASB) reactor. At the same time, the hydrogen production reactor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com