Weak acid washing technology of cellulose fiber fabrics

A cellulose fiber, weak acid technology, applied in the field of textile dyeing and finishing, can solve the problems of sensitive pH value, short immersion time, unstable pH, etc., and achieve the effects of stable pH value, high production efficiency and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

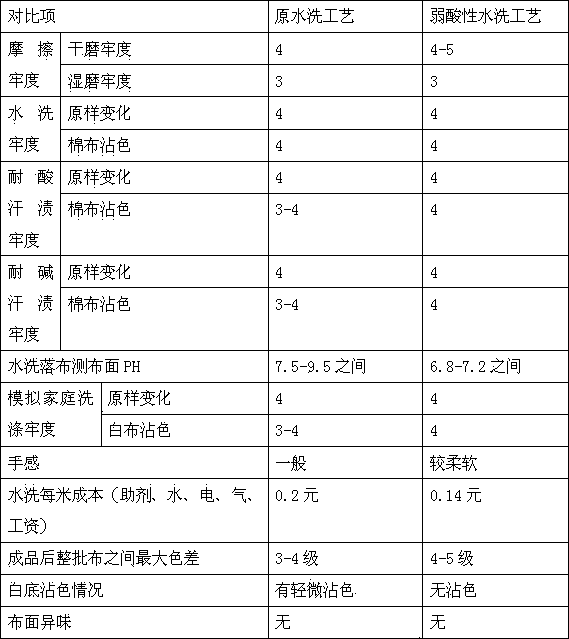

Image

Examples

Embodiment

[0017] Example: Sample: pure cotton 14.58tex*14.58tex, 523.6 strands / 10cm*30 strands / 10cm, width 266.7cm, washed after reactive printing.

[0018] Original washing process:

[0019] The vehicle speed is 45m / min; including four processes of acid neutralization, conventional hot water washing, high temperature water washing and cloth drying; the conventional hot water washing process is generally 3 grids; the high temperature washing process is 4 grids, and the high temperature washing process has four washing grids They are connected to each other, and the lotion liquid surface in each washing compartment can be refluxed; since the cloth surface treated by the dyeing and finishing process is generally alkaline, the lotion (waste liquid from washed fabric) in each washing compartment is also alkaline. Sexuality, affecting the dyeing and finishing effect of fabrics;

[0020] The weak acid washing process of cellulose fiber fabric of the present invention:

[0021] Speed 30m / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com