High-pressure water drilling and cutting integrated machine

A high-pressure water, integrated machine technology, applied in cutting machinery, drill bits, drilling equipment and other directions, can solve the problems of inability to achieve integrated drilling and cutting, easy leakage at the joint of the drill pipe, easy to block the waterway, etc., to overcome the depth of the cutting hole Restricted, overcoming equipment wear, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

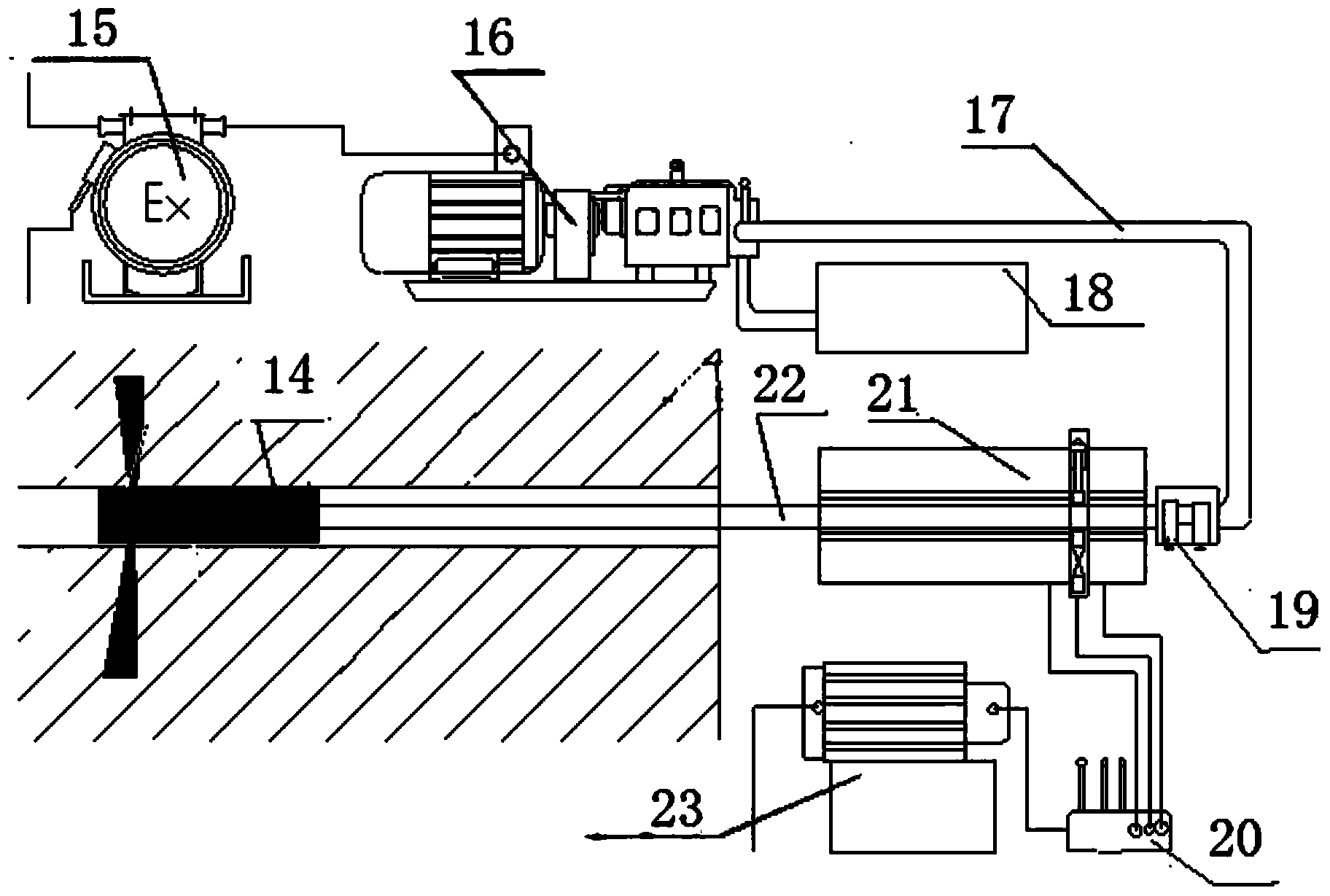

[0030] Such as figure 1 As shown, a high-pressure water drilling and cutting machine of the present invention includes a propeller 21 . A high-pressure drill rod 22 is installed on the propeller 21, and a mine drilling and cutting integrated drill bit 24 is installed on the front end of the high-pressure drill rod 22. Mine drilling and cutting integrated drill bit 24 realizes the automatic conversion of the working state of cutting and drilling according to whether the water fed into the inner cavity is high-pressure water or low-pressure water. The water inlet of the propeller 21 is connected to the high-pressure rubber hose 17 through the rotary faucet 19, and the other end of the high-pressure rubber hose 17 is connected to the water pump 16. The water pump 16 is connected to the water tank 1 and the explosion-proof switch 15 respectively. The propeller 21 is also connected to the propulsion control The propeller 20 is connected and controlled by it, and the propulsion con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com