Coke oven gas purification cooling energy-saving method

A coke oven gas and cooling tower technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of serious energy consumption and power consumption, and achieve accuracy, life improvement, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

[0026] Coke oven gas refining cooling water temperature is generally controlled at 18 °, the accuracy of temperature control has a certain impact on the quality of the product.

[0027] For the Yangtze River Basin and the north of China, the cooling water at 18°C can be naturally cooled in winter. According to the existing technology, chillers are completely used to provide cooling water at 18°C. From the perspective of technology, there is a large space for energy saving. The following embodiment is an example of achieving a process improvement.

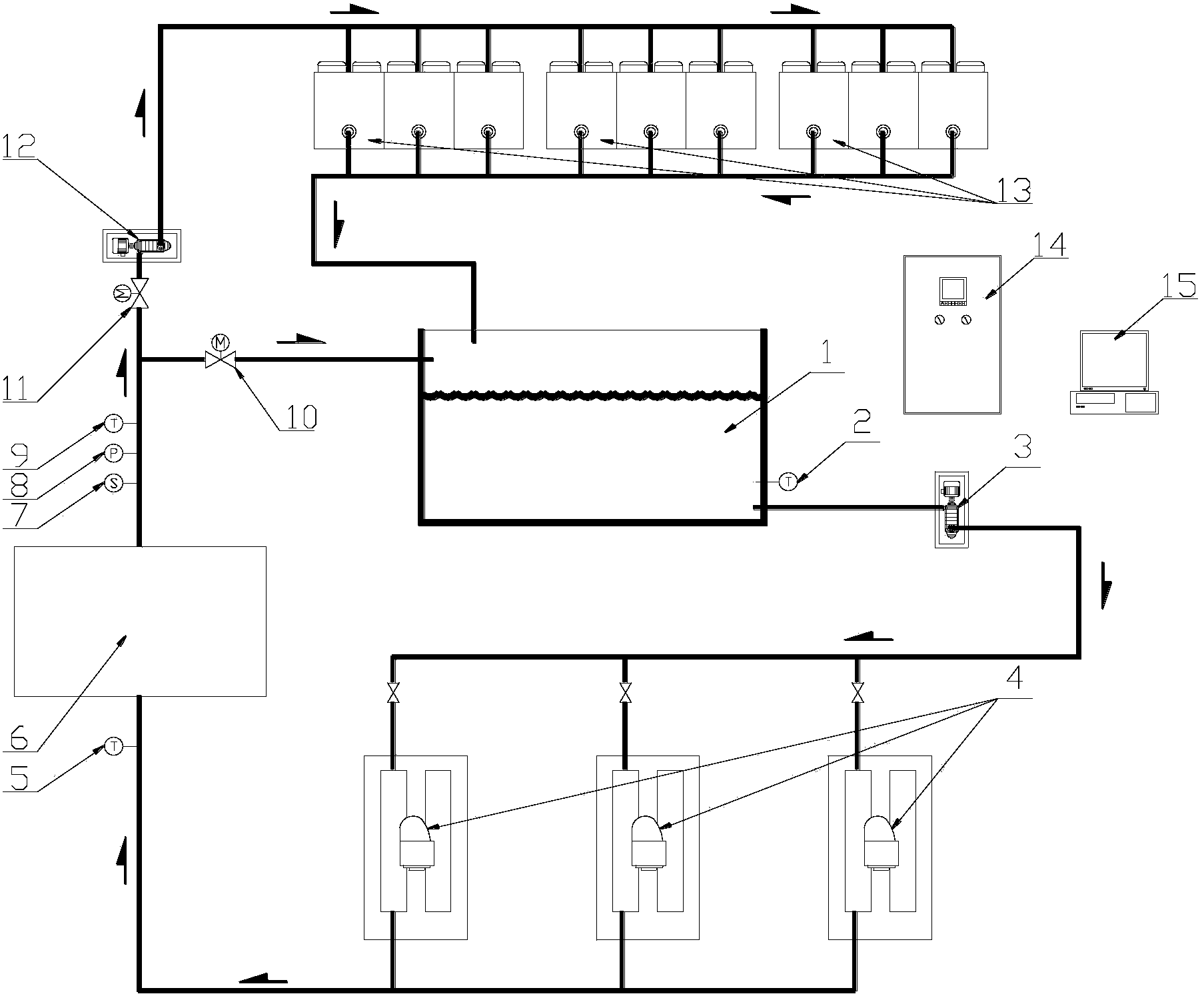

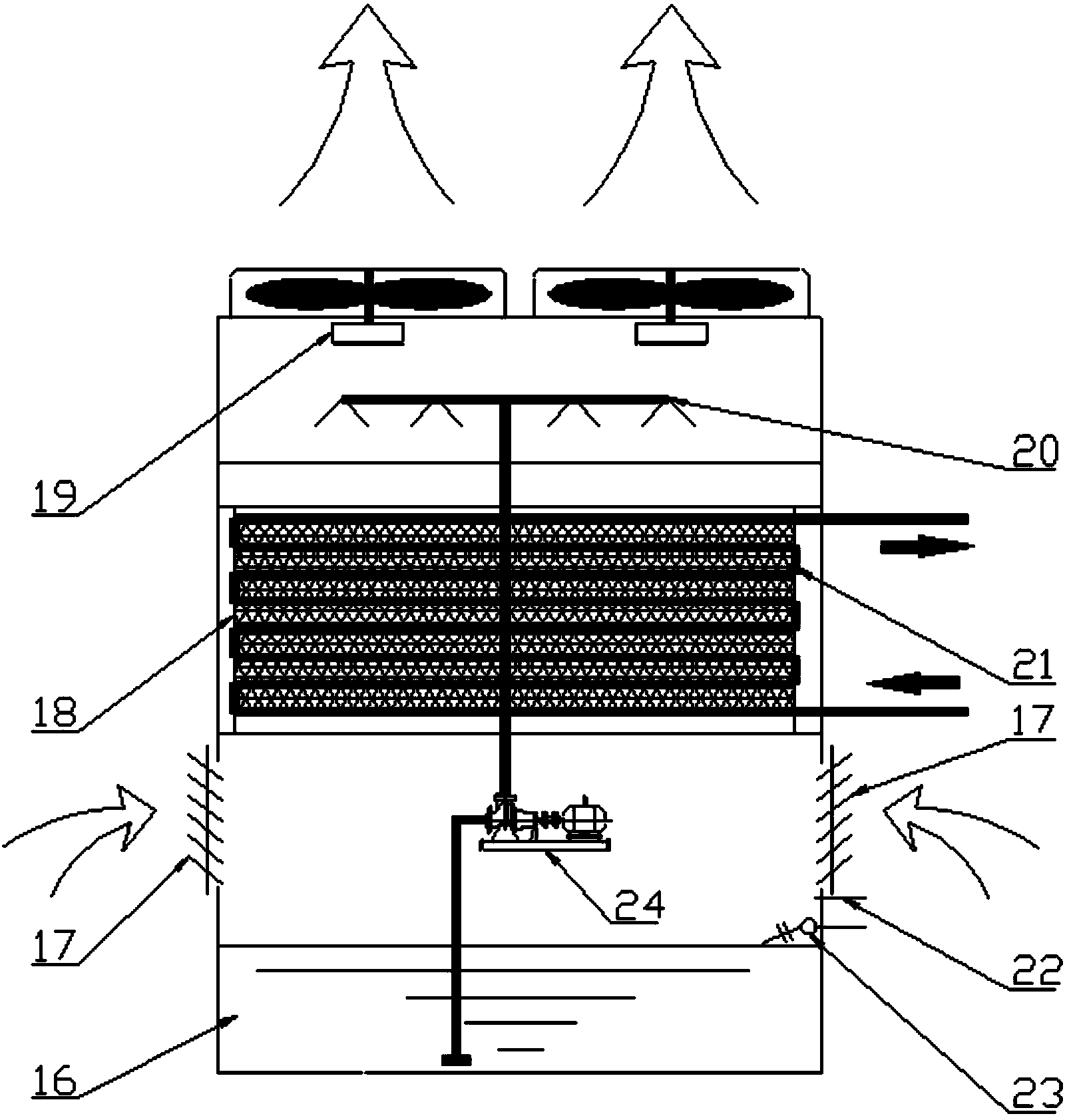

[0028] see figure 1 , coke oven gas refining cooling system winter energy-saving system, consisting of sump 1, temperature sensor Ⅰ, water pump 3, chiller 4, temperature sensor Ⅱ 5, coal fine process heat exchanger 6, flow sensor 7, pressure sensor 8, temperature sensor Ⅲ 9, Electric valve Ⅰ10, electric valve Ⅱ11, supplementary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com