Power supply power distribution system and method

A technology for power distribution and DC power supply, which is applied to control/regulating systems, electrical components, regulating electrical variables, etc. It can solve the problems of high cost of AC UPS, high loss of transmission lines, large system harmonics, etc., and achieves simple structure, Low cost and low ripple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

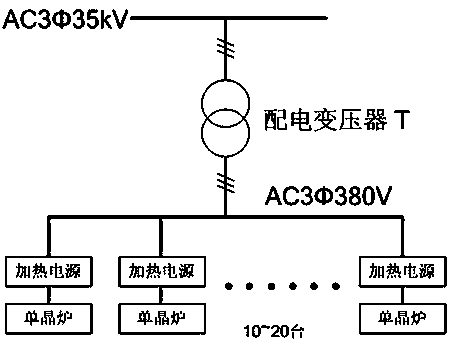

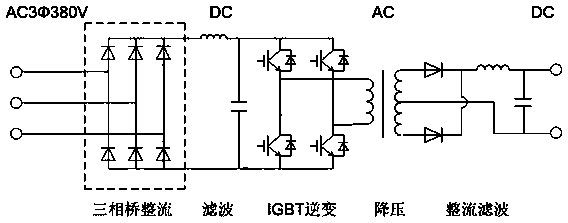

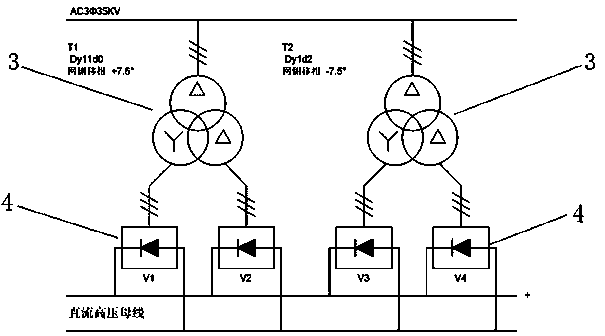

[0032] as attached image 3 , attached Figure 4 , attached Figure 5 As shown, the power distribution system of this embodiment includes a 24-pulse wave rectification circuit 1 and a DC / DC power supply 2 installed on the electrical equipment. The 24-pulse wave rectification circuit 1 includes two 12-pulse wave axial double-split type rectifier transformer 3 and four sets of full-wave rectifier bridges 4, the 24-pulse rectification circuit 1 is connected to the DC / DC power supply 2 through a DC transmission line, and the DC / DC power supply 2 includes an LC filter circuit, an IGBT inverter circuit, Step-down circuit and diode rectification filter circuit.

[0033] This embodiment also provides a new power distribution method on the basis of the above-mentioned power distribution system, as shown in the attached image 3 As shown, the three-phase 35kV high-voltage power from the power grid is connected to the 24-pulse rectification circuit 1, and the step-down rectification i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com