A kind of involute spline broach

A technology of involute splines and cutter teeth, which is applied in the direction of broaching tools, broaching machines, metal processing equipment, etc., can solve the problems of inability to guarantee dimensional accuracy requirements, spline strain, and tool stoppage, etc., and achieves obvious advantages in cost performance , high durability and small broaching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

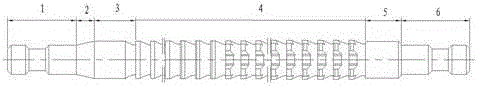

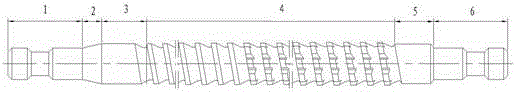

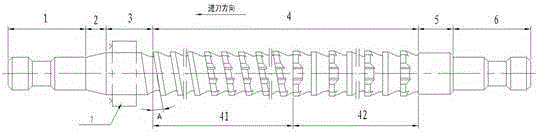

[0014] like image 3 As shown, the involute spline broach of the present invention includes a front handle 1, a transition cone 2, a front guide 3, a tooth portion 4, a rear guide 5 and a rear handle 6, wherein the tooth portion 4 includes a helical-toothed cutter segment 41 and an annular The tooth-shaped cutter segment 42 forms a combined tooth-shaped structure combining spiral and ring. The helical tooth segment 41 is arranged in the front section of the tooth part 4. It is a rough cutting tooth, which forms the effective tooth shape of the involute of the part, and bears most of the cutting amount and the effective tooth surface of the spline involute. Forming, the helix angle A, that is, the blade inclination angle, is controlled between 0°~20°, and the number of helix threads is selected from 2 to 8 according to the actual diameter of the broach and the helix angle requirements. In order to facilitate diameter measurement, an even number of heads is usually selected. nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com