Program control bottle machine

A bottle machine and control terminal technology, applied in the field of program-controlled bottle machines, can solve problems such as difficult production, complex overall structure, and low quality precision of bottle making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

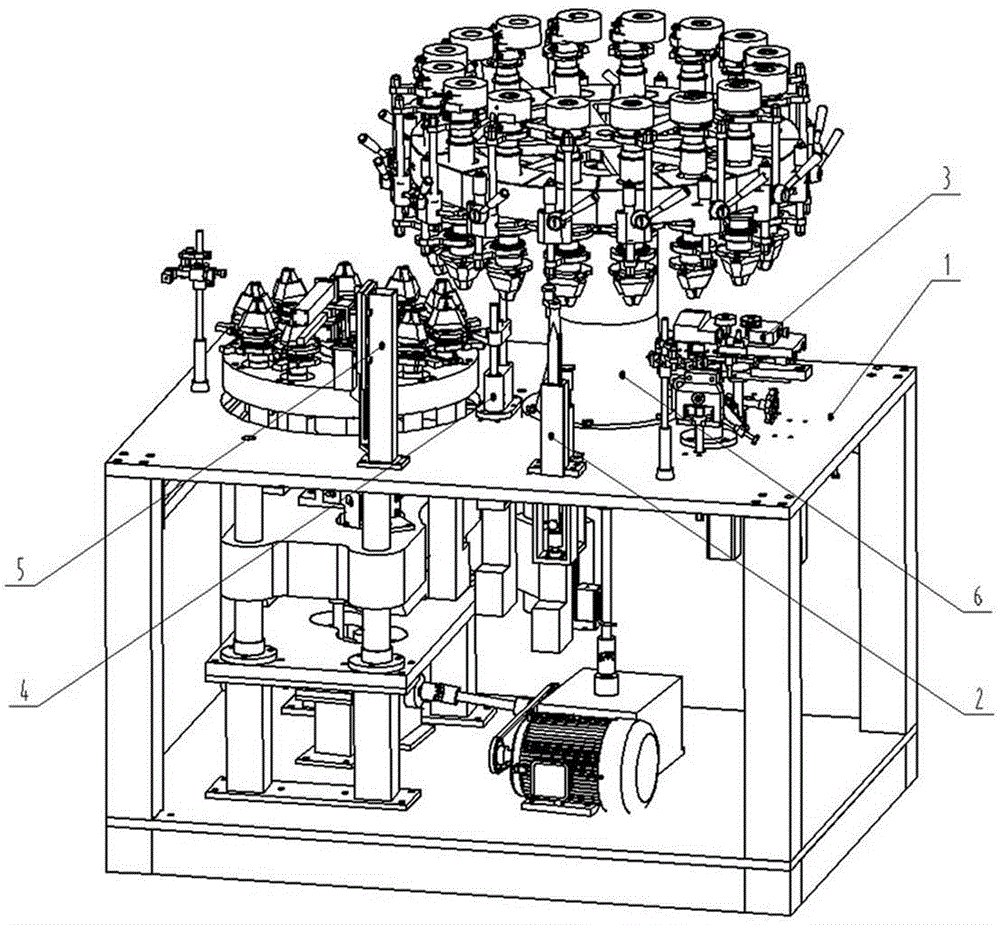

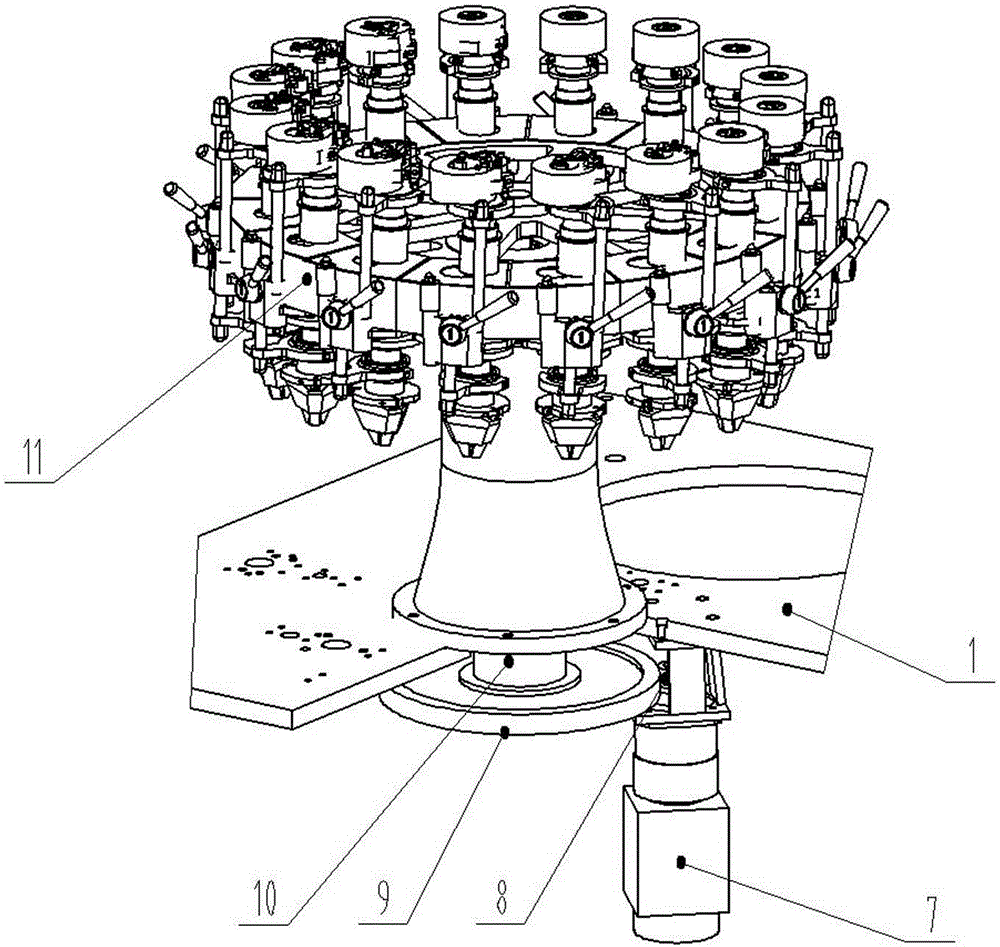

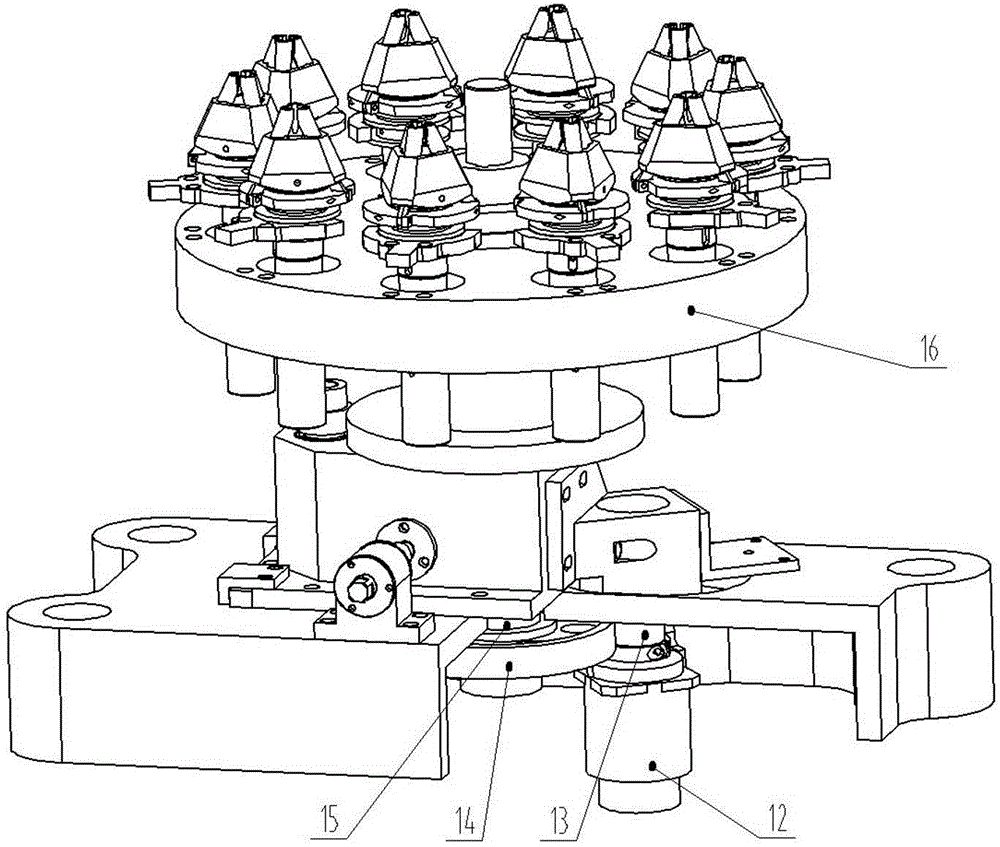

[0014] The present invention will be further described below with the accompanying drawings as examples. This process control bottle machine is an improved invention of the existing bottle making machine, such as figure 1As shown, the stroke control bottle machine includes A-part chuck assembly, bottle body length fixing mechanism 2, neck-making mechanism 3, B-part chuck assembly, and chuck lifting opening and closing mechanism respectively assembled on the body 1. 4. Bottle drop mechanism 5. Heating assembly, revolution drive assembly and rotation drive assembly assembled in the lower part of the fuselage; the chuck assembly of part A is assembled on the fuselage 1 through the support sleeve 6, and the bottle body is fixed in length The mechanism 2 and the neck mechanism 3 are respectively arranged on the fuselage 1 corresponding to the controlled chuck of the chuck assembly of part A; the chuck assembly of part B is arranged on the fuselage 1 on the side of the chuck assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com