Preparation method of 2-(aminoxy) ethanol

A technology of amino-oxygen and ethanol, which is applied in the direction of organic chemistry, can solve the problems of low product purity and low reaction yield, and achieve the effects of simple operation, low cost and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that, for those skilled in the art, several modifications and improvements can be made without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

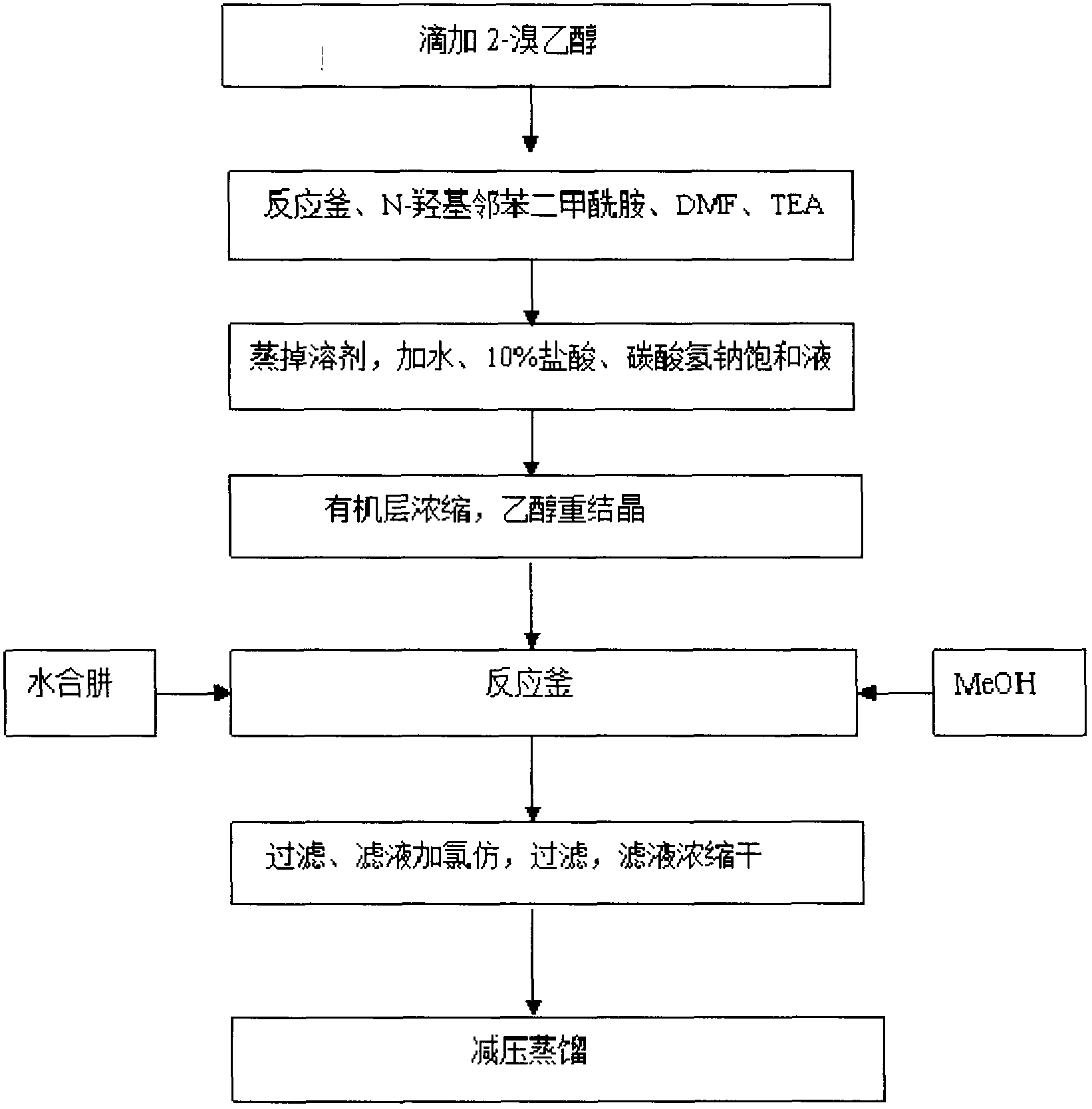

[0019] A kind of preparation method of 2-(amino oxygen) ethanol, comprises the following steps (as figure 1 shown):

[0020] Step (1), sequentially add 1 weight part of N-hydroxyphthalamide, 4 weight parts of DMF (dimethylformamide) and 1.24 weight parts of TEA (triethylamine) to the reactor;

[0021] Step (2), heating the reaction kettle to 60°C, adding 1.152 parts by weight of 2-bromoethanol dropwise, controlling the reaction temperature to <95°C;

[0022] Step (3), after the dropwise a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com