An Analytical Modeling Method for Ambient Temperature of Heavy Machine Tool

A technology of environmental temperature and modeling method, which is applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve the problems of undiscovered and undiscovered heavy machine tool environmental temperature analysis modeling, compensation accuracy failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

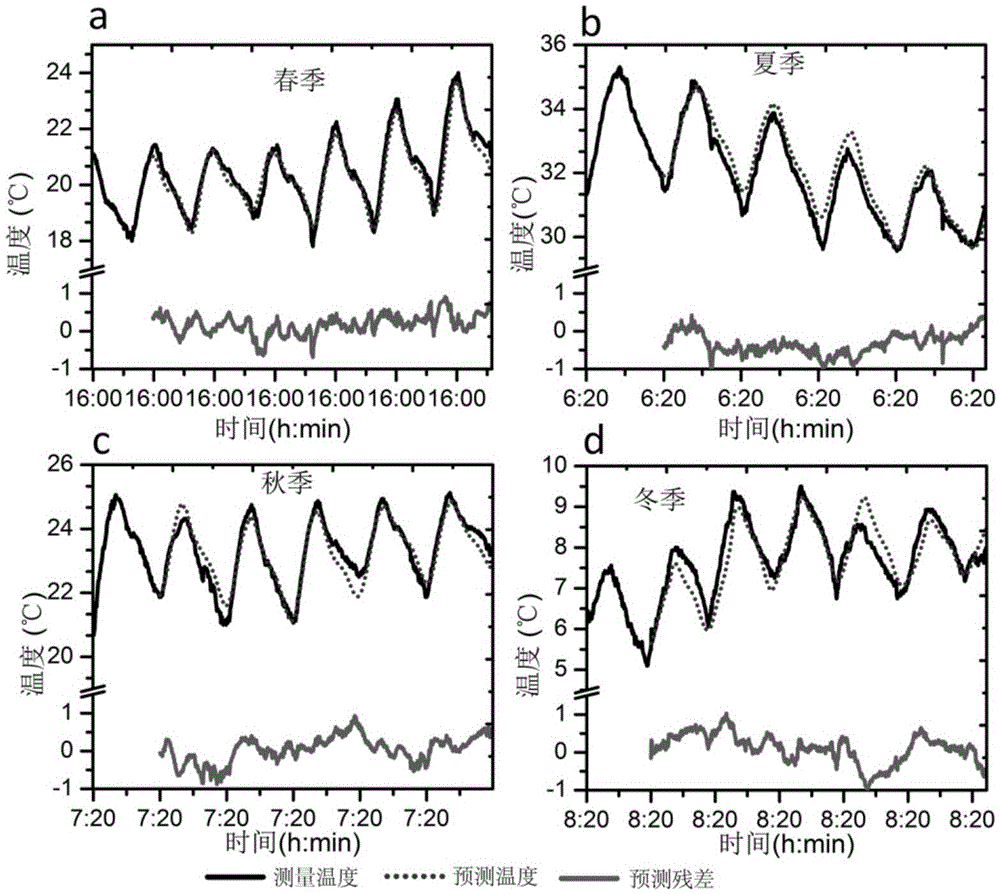

[0039] In conjunction with the accompanying drawings, the present invention will be described in detail with the implementation process of the decomposition prediction of the ambient temperature of an XK26 gantry milling machine.

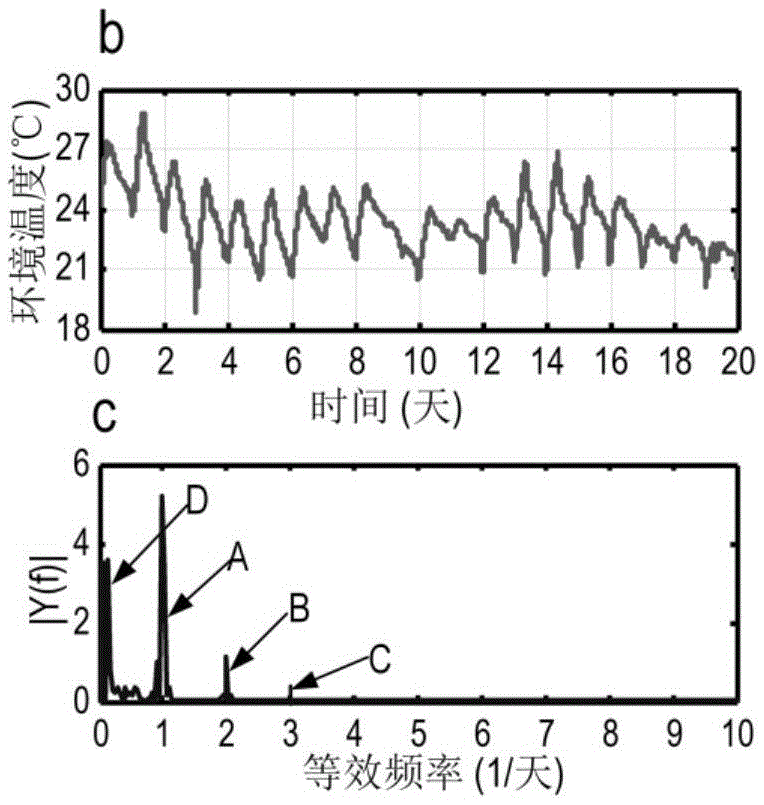

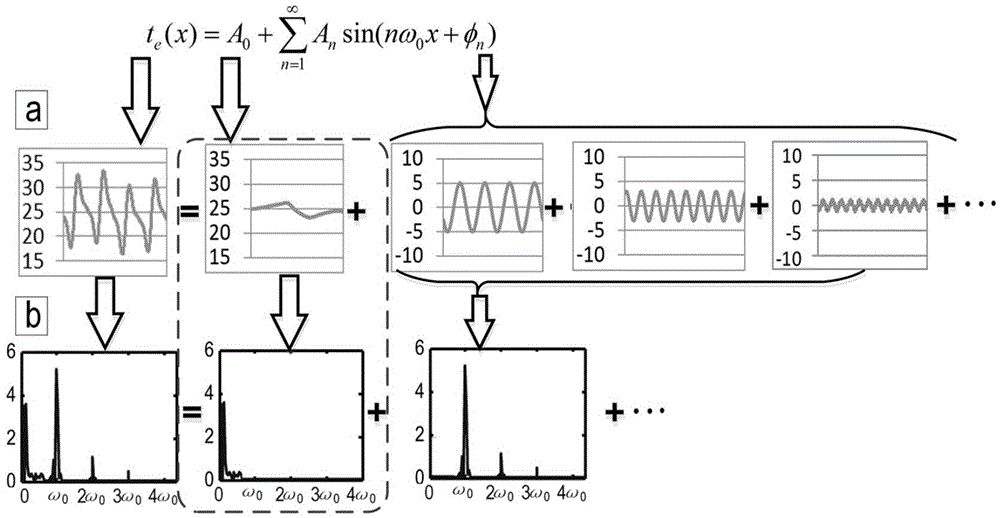

[0040] attached figure 1 It shows an XK26 gantry mobile boring and milling machine and the ambient temperature measurement data of the workshop where it is located for 20 consecutive days (the interval between measuring points is 10 minutes) and the amplitude spectrum obtained by Fourier transform, in which the mean value of the Fourier series is the moving average data of the time series Instead, the low-frequency part of the temperature signal is retained, and the fundamental frequency and double frequency part signals are replaced by the superposition of harmonic items of different frequencies, amplitudes, and phases.

[0041] 1. Ambient temperature temperature measurement

[0042] The ambient temperature measurement system of the machine tool u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com