Oven controlled crystal oscillator

一种恒温槽、振荡器的技术,应用在输出稳定、电气元件等方向,能够解决水晶振子安装位置偏离、温度稳定性不够充分、难以降低高度方向的尺寸等问题,达到实现低背化、提高热响应性及温度稳定性、温度特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

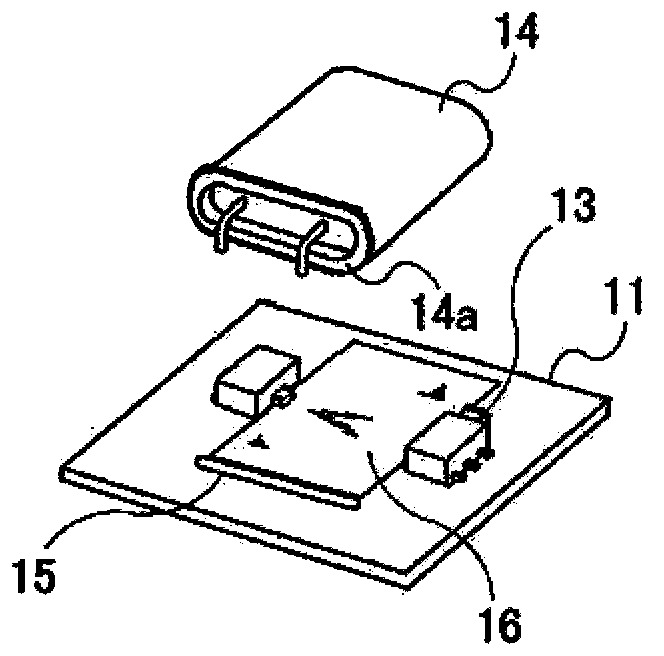

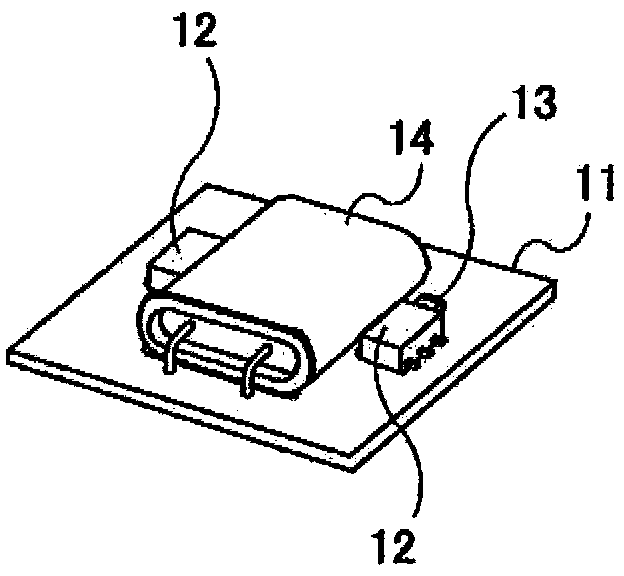

[0096] [First embodiment: FIG. 1(a), FIG. 1(b)]

[0097] The structure of the crystal oscillator with a constant temperature bath according to the first embodiment of the present invention will be described using FIG. 1( a ) and FIG. 1( b ). Fig. 1 (a) and Fig. 1 (b) are schematic explanatory views showing the structure of an oscillator used in a crystal oscillator with a constant temperature bath according to the first embodiment of the present invention, and Fig. 1 (a) is an exploded explanatory view, Figure 1(b) is an explanatory diagram of the appearance.

[0098] As shown in Fig. 1 (a) and Fig. 1 (b), the oscillator of the crystal oscillator with constant temperature tank (the first crystal oscillator with constant temperature tank) of the first embodiment of the present invention is as follows: On one surface of the circuit board 11 , a heat source 12 , a thermistor 13 , and a crystal oscillator 14 are provided.

[0099] That is, the first crystal oscillator with const...

no. 2 Embodiment approach

[0172] [Second embodiment: FIG. 3(a), FIG. 3(b)]

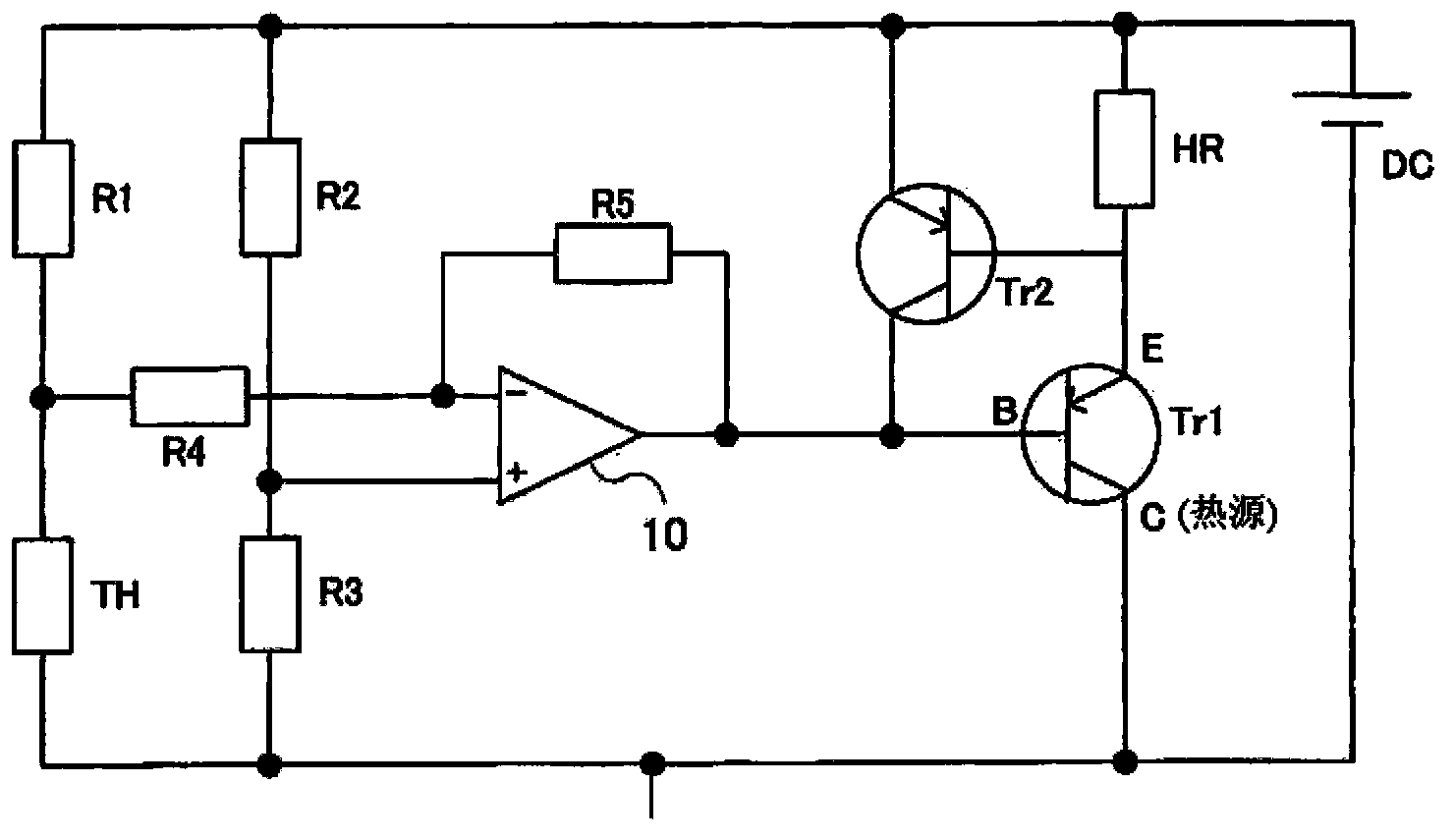

[0173] Next, the configuration of a crystal oscillator with a constant temperature bath according to a second embodiment of the present invention will be described using FIG. 3( a ) and FIG. 3( b ). Fig. 3 (a) and Fig. 3 (b) are schematic explanatory diagrams showing the structure of an oscillator used in a crystal oscillator with a constant temperature bath according to a second embodiment of the present invention, and Fig. 3 (a) is an appearance explanatory diagram, Fig. 3(b) is a partial explanatory diagram.

[0174] A crystal oscillator with a constant temperature bath (a second crystal oscillator with a constant temperature bath) according to a second embodiment of the present invention includes: a cylindrical crystal oscillator shown in FIGS. 6( a ) and 6 ( b ), and figure 2 The temperature control circuit shown.

[0175] As described above, the cylindrical crystal resonator has long-term stable frequency characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com