Improvements regarding waste disposal

A technology for treating chambers and municipal solid waste, which is applied in the fields of solid waste removal, pyrolysis treatment of sludge, and biomass drying, etc., and can solve the problems of reducing the heat transfer efficiency of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

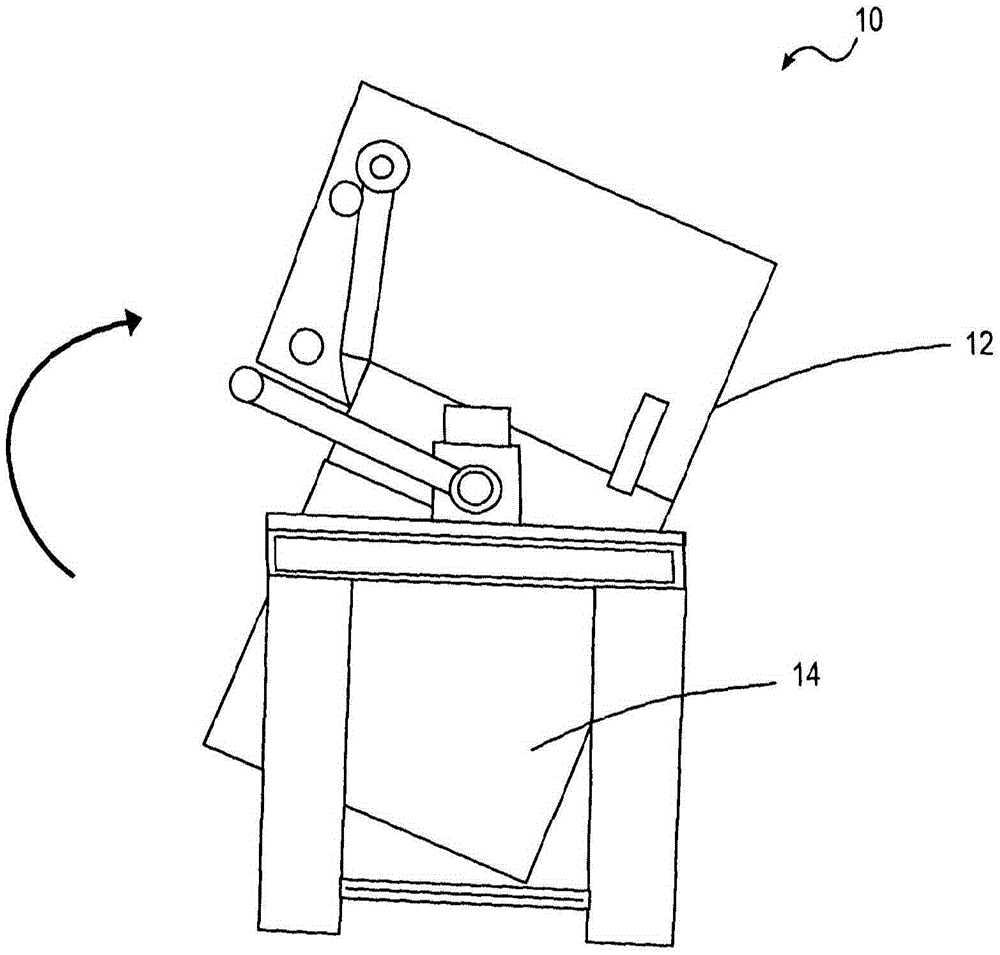

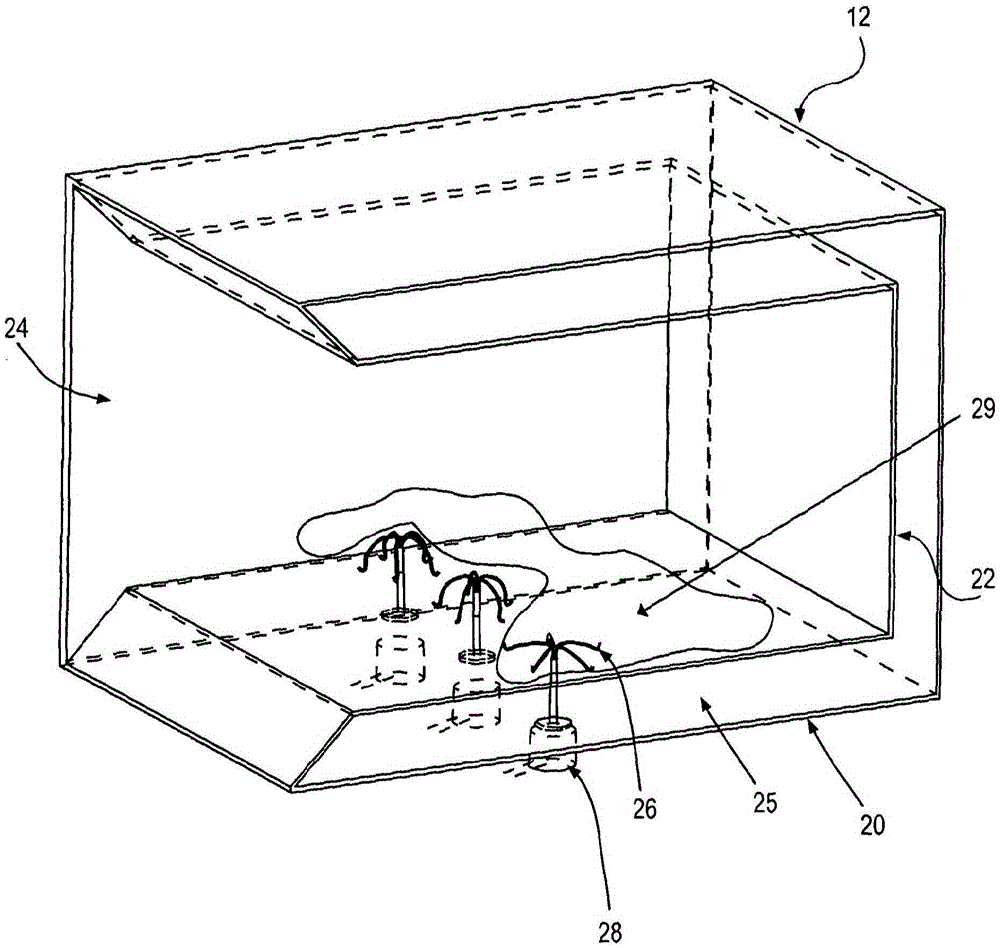

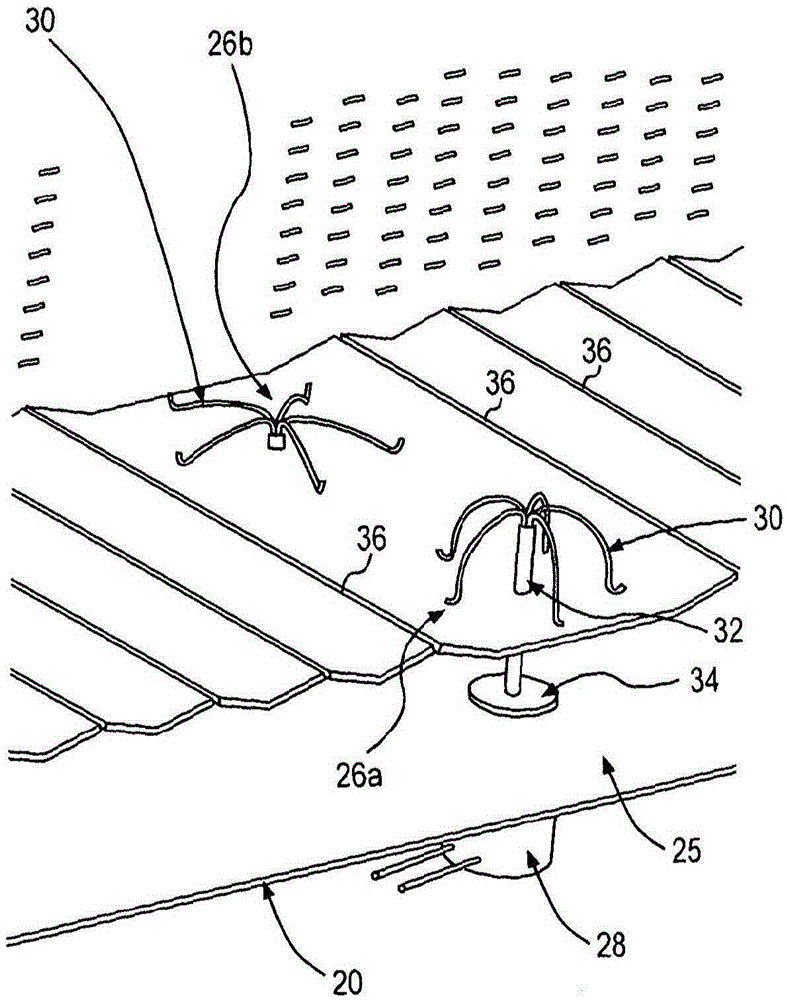

[0029] see figure 1 , shows a rotary furnace. The furnace 10 includes a processing chamber 12 and a charging box 14 connected to the processing chamber and allowing waste to be added to and removed from the furnace. The basic principles of the furnace's operation can be found in prior art document WO2004 / 059229. The waste to be processed is loaded into a charging box which is then connected to the rotary kiln. As the material within the furnace is heated, the furnace rotates to decompose the material. The material may be heated in an atmosphere of zero or approximately zero percent oxygen such that the material pyrolyzes in the furnace to produce gas.

[0030] Although the prior art is described as having an integral afterburner for combusting the gases being produced, it will be appreciated that the afterburner may be separate from the furnace and connected to it by piping. Those skilled in the art will appreciate that an afterburner may be used to combust gases produced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com