Method for preparing joint made of dissimilar material by firstly ultrasonically prefabricating and secondly welding transition belt

A technology of dissimilar materials and transition zones, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as the reduction of dynamic mechanical properties, achieve simple methods, excellent mechanical properties and usability, and avoid process exploration and related problems The effect of process aids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

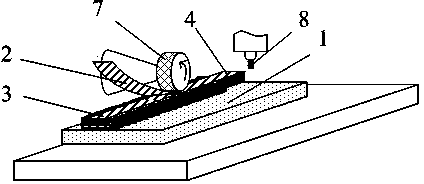

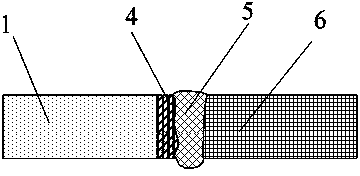

Method used

Image

Examples

Embodiment 1

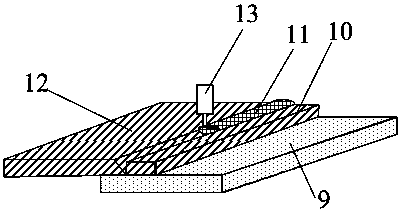

[0030] Using the present invention as image 3 As shown, using 0.2mm thick aluminum foil on the 1mm thick copper plate (9) by ultrasonic rolling, 7 layers of aluminum foil are sequentially stacked and welded on the surface of the copper plate (9) to form a stacked layer with a width of about 5mm, and then Use the milling cutter that comes with the system to machine the three sides of the stacked layer to form a boss-shaped transition zone (10) composed of aluminum foil with a height of 1mm and a width of 4mm, and then connect the 1mm-thick aluminum plate (12) with the transition zone as shown in the figure. The belt (10) is flat butt-jointed, and finally the gas metal arc welding torch (13) is used for welding with aluminum wire to form a weld (11) to realize the connection of dissimilar materials between the copper plate (9) and the aluminum plate (12). Tensile tests were carried out after welding, and the joints were all broken at the fusion welding seam, and the strength wa...

Embodiment 2

[0032] Using the present invention as Figure 4 As shown, 0.2 mm thick aluminum foil is used on a 4 mm thick steel plate (14) by ultrasonic roll welding, and 7 layers of aluminum foil are sequentially stacked and welded on the surface of the steel plate (14) to form a stacked layer with a width of about 5 mm. Then use a milling cutter to machine the three sides of the stacked layer to form a boss-shaped transition zone (15) with a height of 1 mm and a width of 4 mm, which is composed of stacked and interconnected aluminum foils, and then connect the 4 mm-thick aluminum plate (16) with the transition as shown in the figure. The belt (15) is vertically butt-jointed, then put into a vacuum furnace, and the transition belt (15) and the aluminum plate (16) are welded by means of diffusion welding. After welding, the shear test is carried out. Since the transition reaction caused by the contact between the aluminum plate (16) and the steel plate (14) is avoided by diffusion welding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com