A control system of bridge cable detection robot

A control system and robot technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of ineffective control of wheel errors, limited travel speed, and detection of workers' falls, so as to improve flexibility and work efficiency. Enhanced self-adaptive ability and prevent crashes due to malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

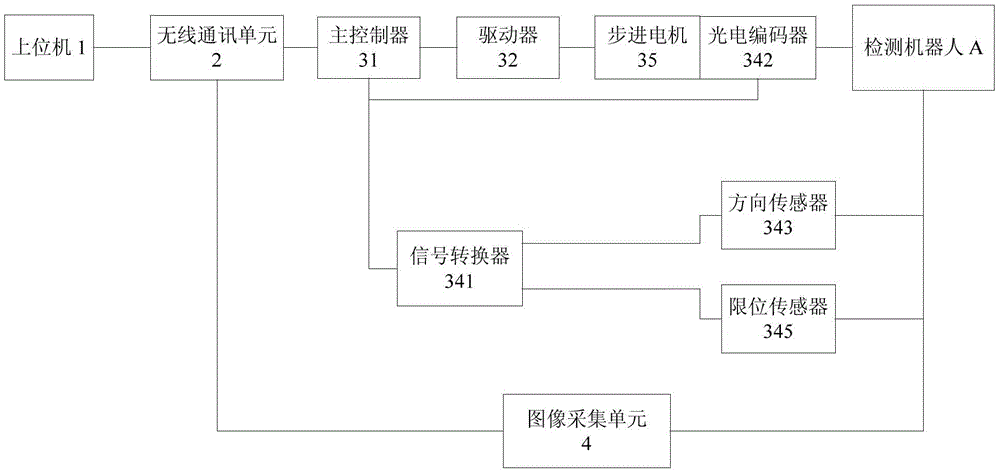

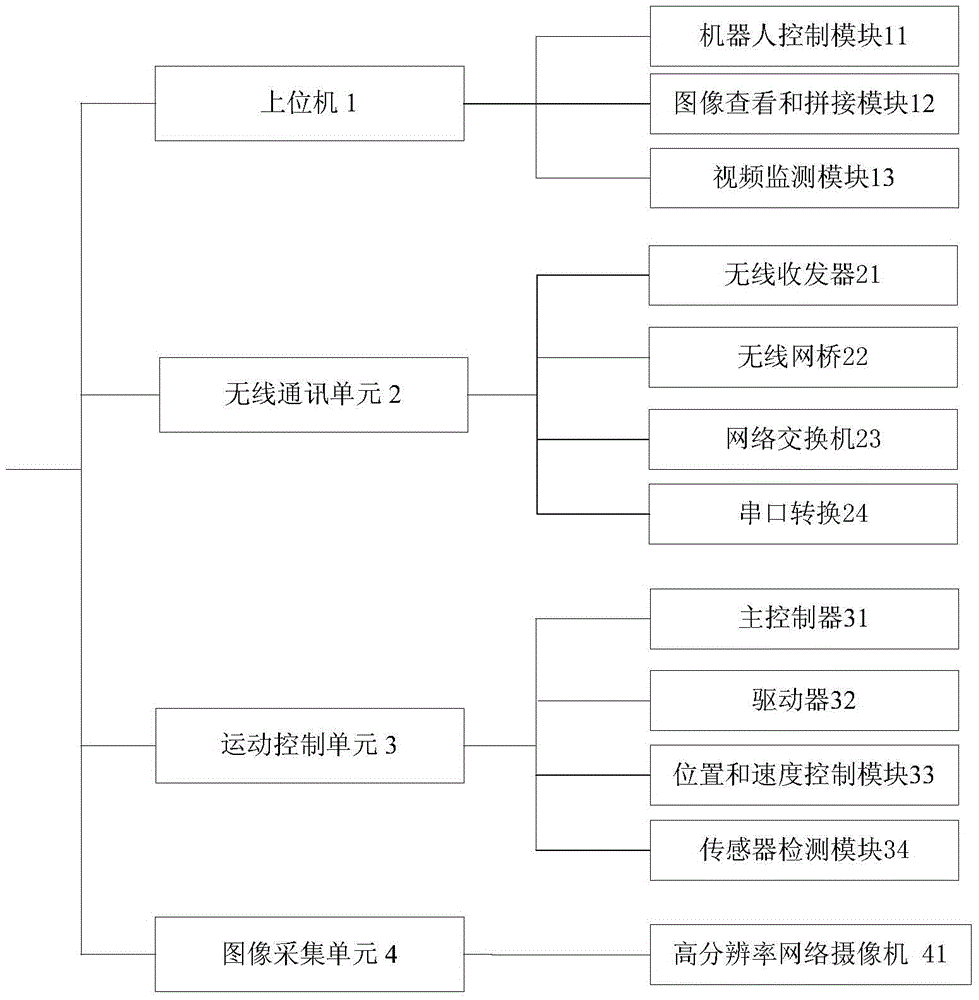

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is only to enable the advantages and feasible solutions of the present invention to be understood by those skilled in the art, but not to limit the present invention and its application or use. Other implementation modes obtained according to the present invention also belong to the technical innovation scope of the present invention.

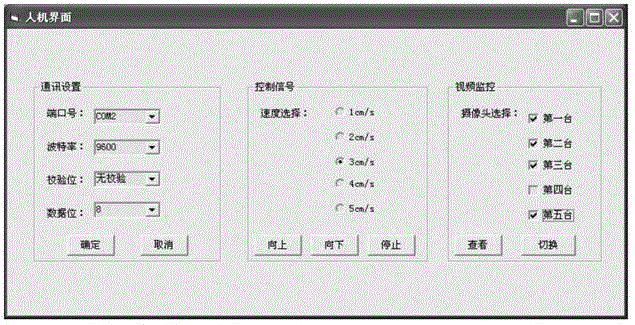

[0031] With the rapid development of electronic technology and computer technology, the main controllers of single-chip microcomputer, ARM, PLC, etc. are also widely used in aerospace and industrial control. , high reliability, and strong communication functions, which are significantly higher than other controllers and have been applied in industrial process control. Because PLC has significant advantages in switching value control, and in the control system of the present invention, the dead we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com