Axially-moving rope transverse vibration measurement device and method

A technology of lateral vibration and axial movement, used in measuring devices, using optical devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effects of improving stability and accuracy, simplifying control systems, and reducing control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

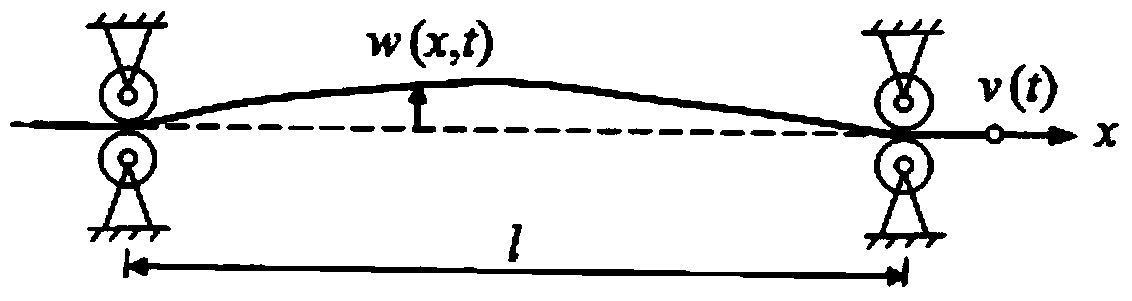

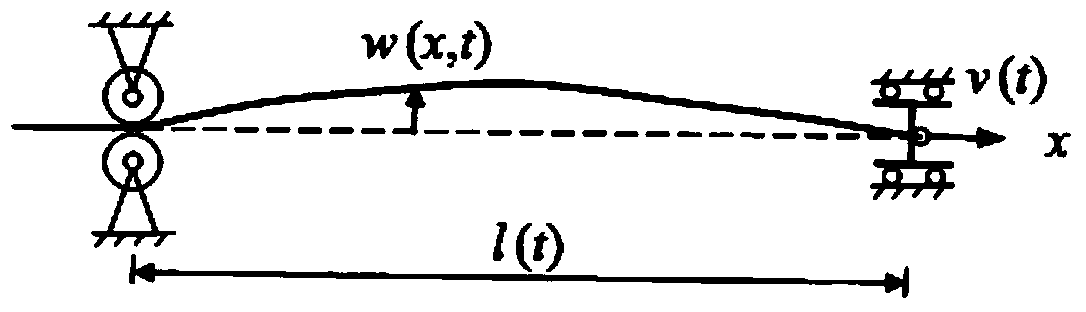

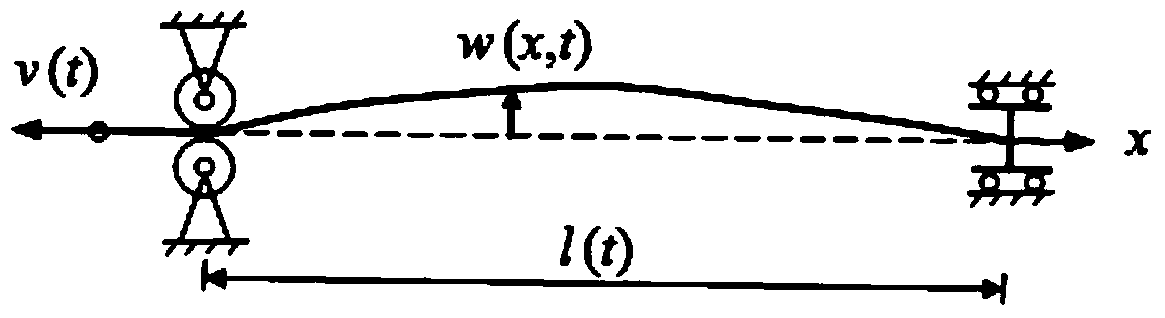

[0035] see figure 2 and image 3 , the structure of the axially moving rope lateral vibration measuring device in this embodiment is set as:

[0036]The rope circulation transmission unit is set, is to be by driving pulley 13, driven pulley 2, tension pulley 28, tension sensor gear train 6 and the first stepper motor 14 that is used to drive driving pulley 13 to form circulation gear train, is the rope of closed loop. 3. A rope circulation transmission unit in a vertical plane is wound on the circulation wheel train; the driving wheel 13, the driven wheel 2 and the tensioning wheel 28 are fixedly arranged on the bottom plate 1; the bottom plate coordinate axis is set, and the bottom plate coordinate axis refers to the rope moving The coordinate axis fixed on the bottom plate 1 in the direction.

[0037] Displacement measurement system is set: it includes a linear guide rail 5 fixedly installed above the rope and parallel to the moving direction of the rope, a first slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com