Tungsten carbide tooth tip square tooth saw chain

A technology of cemented carbide teeth and tooth shapes, which is applied in the field of chain saws, can solve the problems of uneconomical and shortened service life of saw chains, and achieve the effects of increased durability, increased service life and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

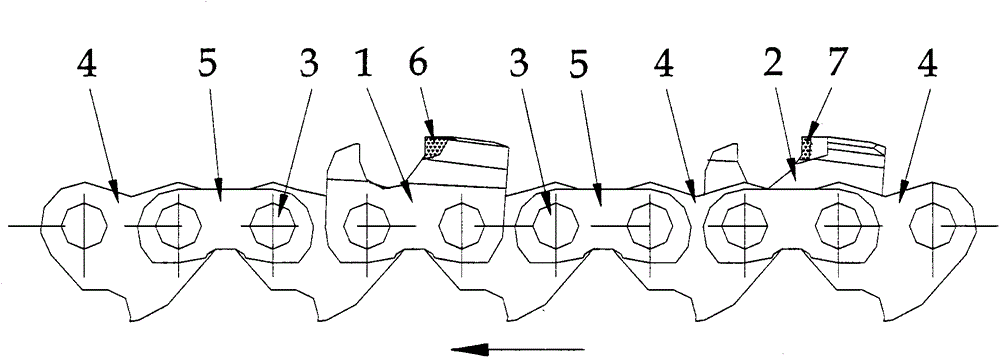

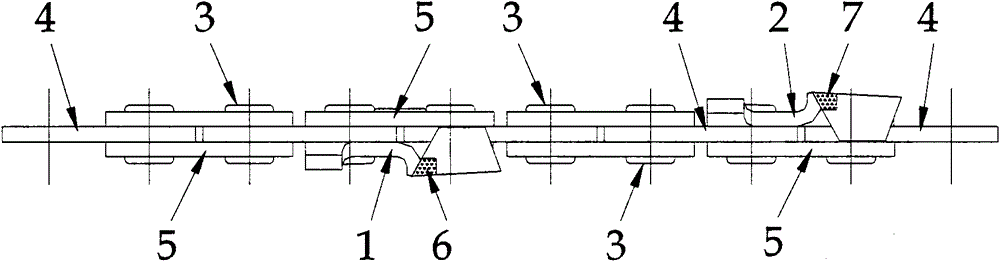

[0022] Figure 1-Figure 2 Among them, the carbide-tipped square-toothed saw chain is composed of a left cutter chain 1, a right cutter chain 2, a chain shaft 3, a transmission piece 4 and a connecting piece 5, and the left cutter chain 1 is welded with a left carbide Tooth piece 6, is welded with right cemented carbide tooth piece 7 on the right cutter chain piece 2. The structures and shapes of the left cutter chain piece 1 and the right cutter chain piece 2 are completely symmetrical.

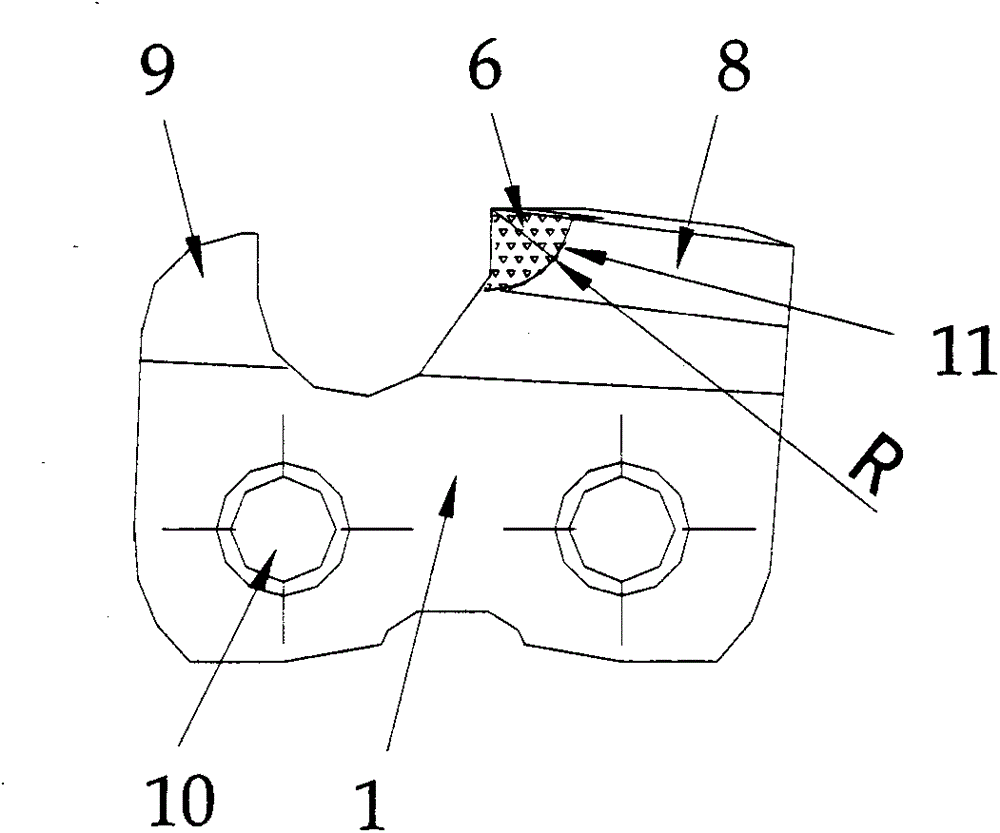

[0023] Figure 3-Figure 14 Among them, both the left cutter chain piece 1 and the right cutter chain piece 2 are composed of cutting teeth 8 , material limiting teeth 9 , connecting parts and two riveting holes 10 . The left hard alloy tooth block 6 and the right hard alloy tooth block 7 are fan-shaped prisms, and most of the welds 11 welded with the cutting teeth 8 are cylindrical surfaces. This structure can make the left hard alloy tooth block 6 and the right hard alloy tooth block The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com