Vacuum compression moulding machine

A vacuum pressure and forming machine technology, applied in the field of pressure forming machines, can solve the problems of mold deformation, high manufacturing cost, high use cost and energy consumption cost, product size impact, etc. occupied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

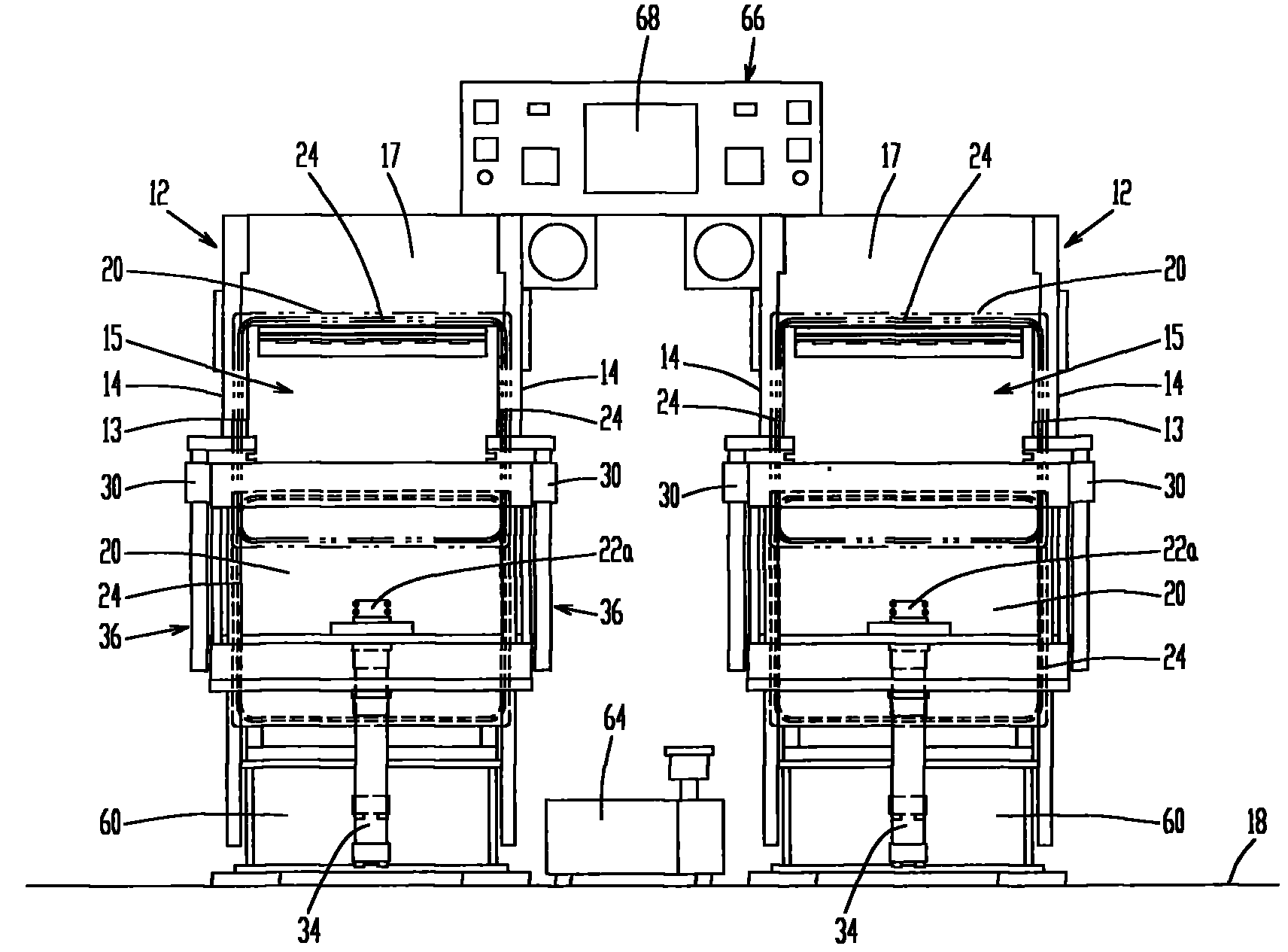

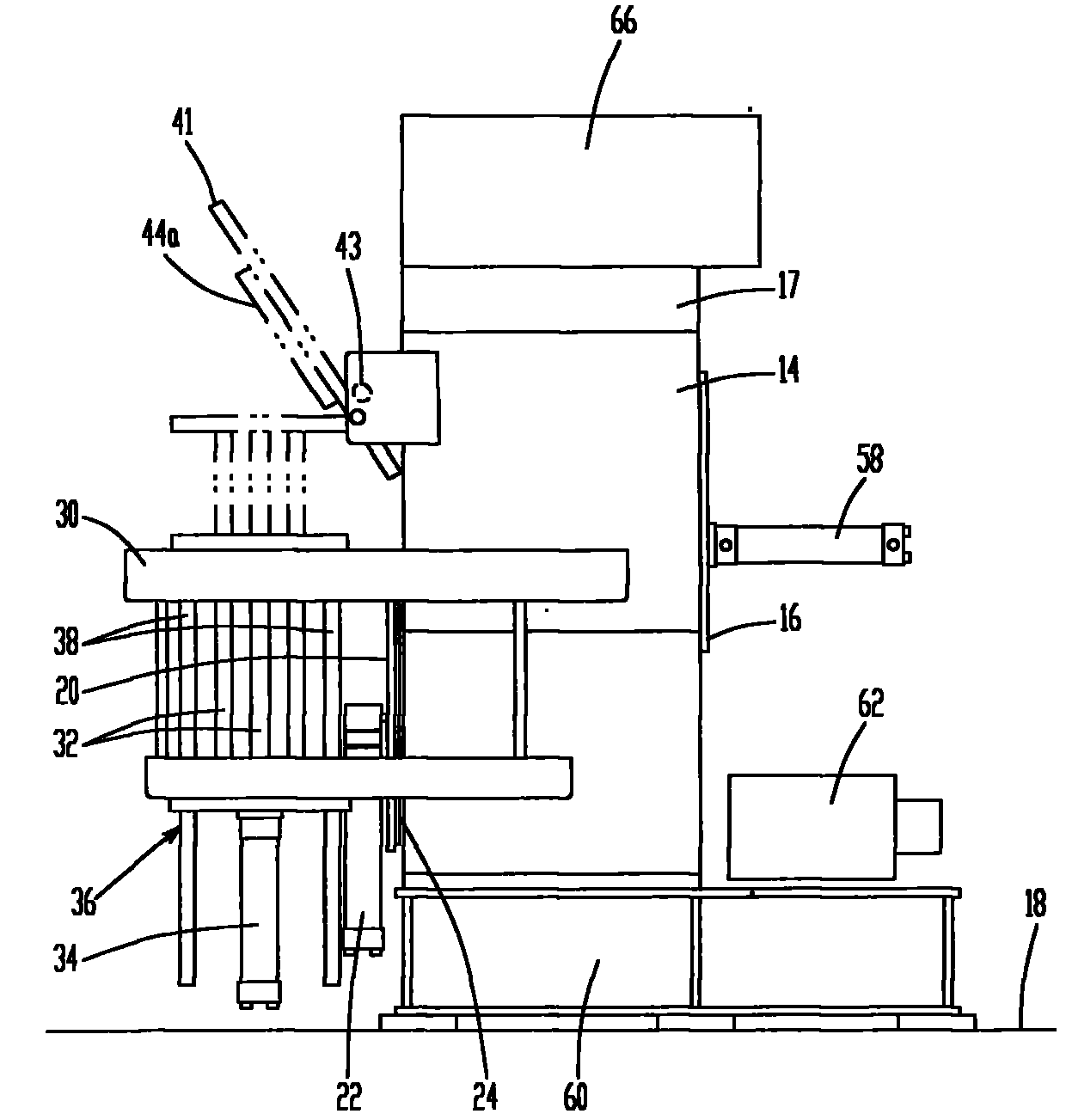

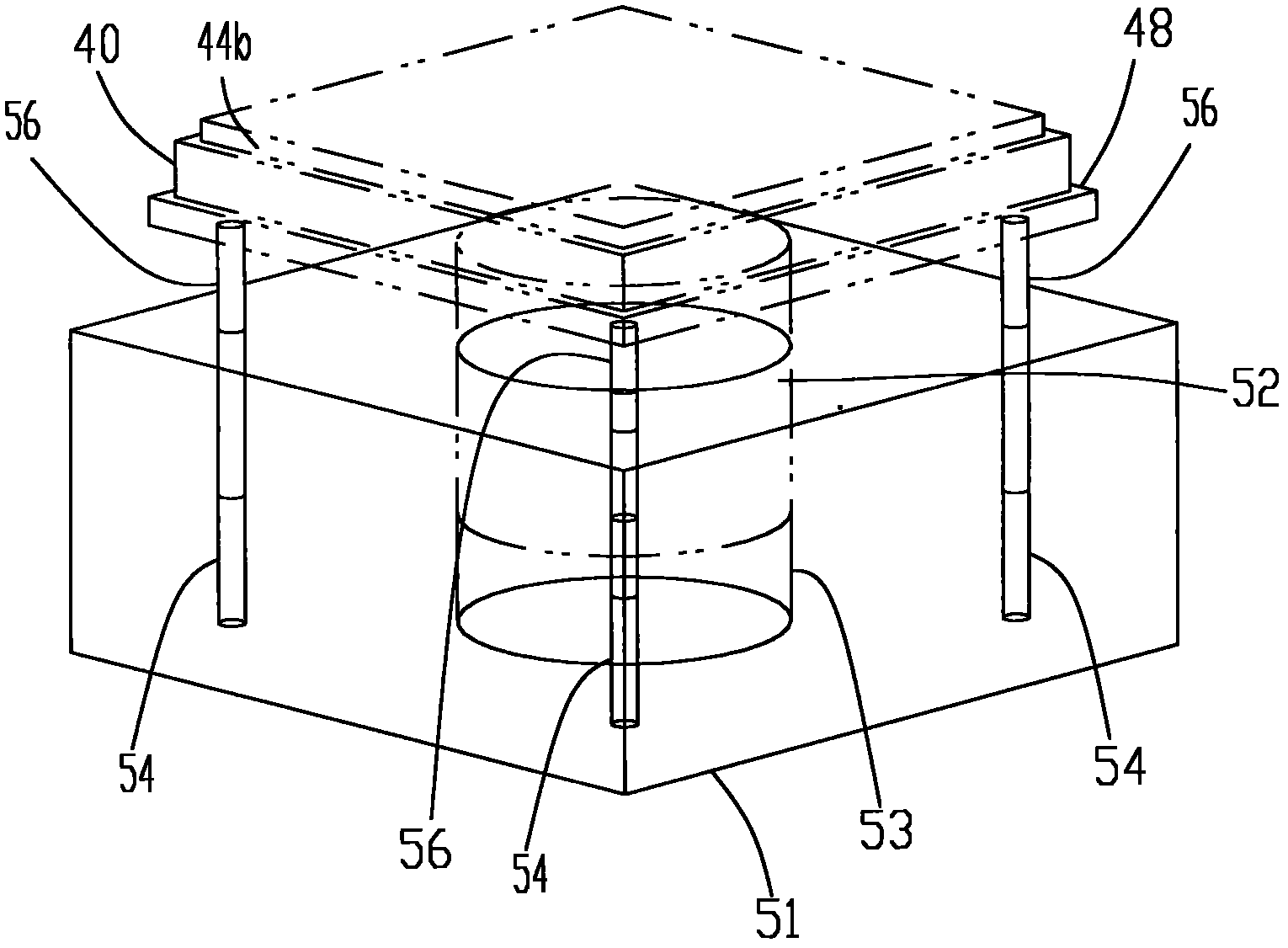

[0024] The following is a schematic illustration of the embodiment of the design. Figure 1-Figure 4 A representation of an embodiment designed for this purpose. The vacuum pressure forming machine of this embodiment is 2 hosts 12 as a group, the host 12 shown in the figure is a hexahedron shape, certainly this host 12 can also be processed into other shapes as required. Each equipment host 12 is formed of a pair of side plates 14 and a top plate 17 to form a cuboid and arranged on a bottom plate 18 . A rectangular opening 13 is provided on the front of the main body 12 of the device, and communicates with a vacuum chamber 15 serving as a molding space in the main body 12 . The vacuum chamber 15 of the equipment host 12 is composed of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com