High line pressure compound silica gel roller

A technology of silicone roller and high wire, which is applied in the field of high-line pressure composite silicone roller, which can solve the problems of affecting the scope of use, low strength of silicone rubber, and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

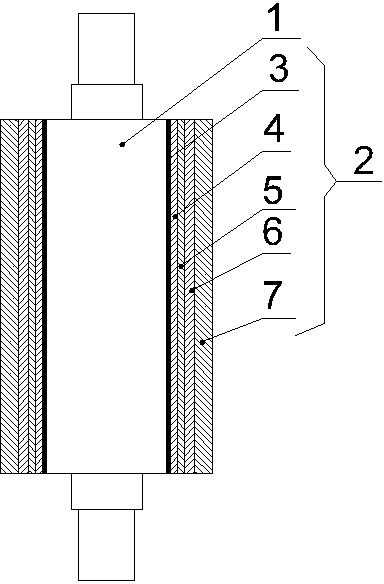

[0009] as attached figure 1 As shown, the high-line pressure composite silicone roller includes a steel roller core 1 and a coating 2 on the surface of the roller core, wherein the coating 2 is composed of an adhesive layer 3 and an EPDM rubber layer 4 from the bottom to the surface. , SEP rubber layer 5, modified silicone rubber layer 6 and silicone rubber layer 7.

[0010] EPDM rubber can resist heat, light, oxygen, especially ozone, and has good insulation. Covering the EPDM layer on the surface of the primer can effectively increase the insulation performance of the silicone roller and prevent the qualitative change of the primer layer. The emergence of the phenomenon of core removal of the cladding. SEP rubber is a material made by mixing and denaturing EPDM rubber and silicone rubber, which can effectively improve the heat resistance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com