A kind of coating for galvanized sheet and preparation method thereof

A galvanized sheet and coating technology, applied in the field of paint, can solve problems such as wasting time, wasting energy, and low decorative performance, and achieve the effects of improving compatibility, saving energy, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] One, embodiment 1 synthetic LH-60 resin

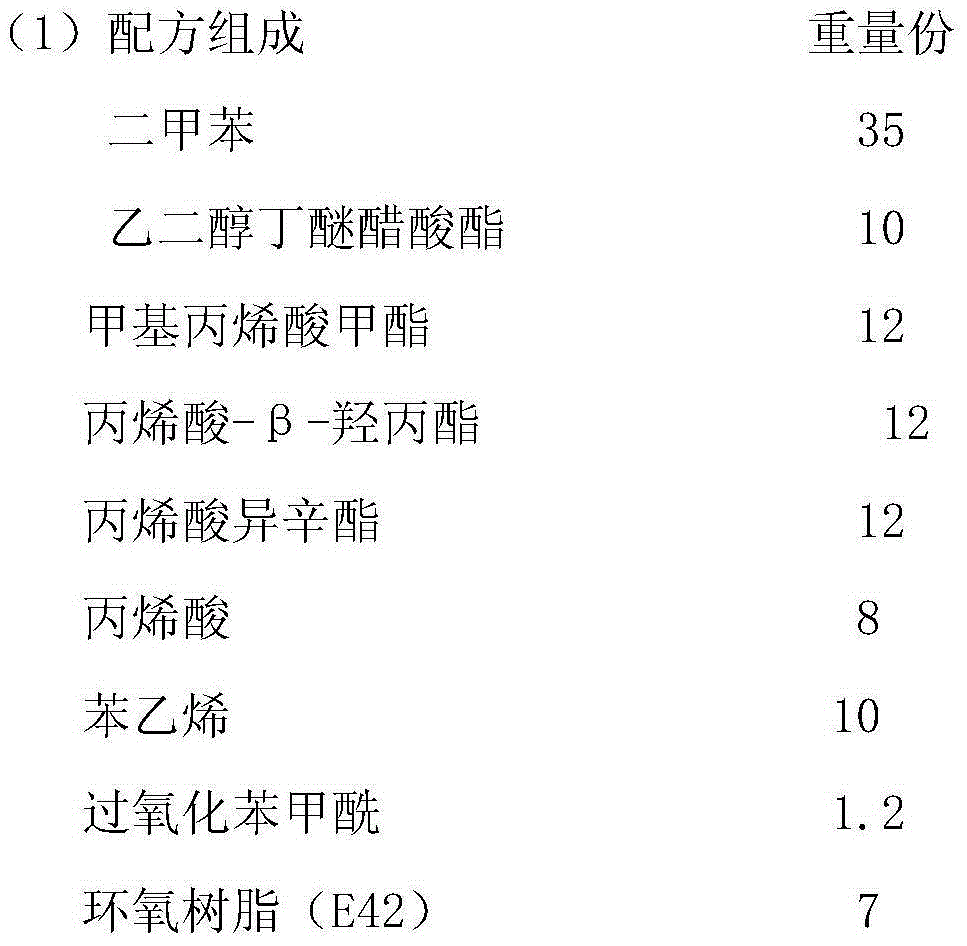

[0027]

[0028] (2) Process

[0029] ①. Make a mixture of monomer and 80% initiator in the formula amount for later use;

[0030] ②. Add epoxy resin, 90% formula xylene and butyl ester into the reaction kettle, raise the temperature to 90°C, keep stirring until the epoxy resin is completely dissolved, then start to drop the mixture prepared in ①, in 2- 2. After 6 hours of dripping the mixture, heat it at 95±2°C for 2 hours, then raise the temperature to 105±2°C and add the mixed solution of the remaining initiator (the initiator is dissolved in the mixed solvent), drop it in 1 hour, and keep it for more than 1 hour;

[0031] ③. When the measured conversion rate is above 98%, cool down, filter, and discharge to obtain the resin.

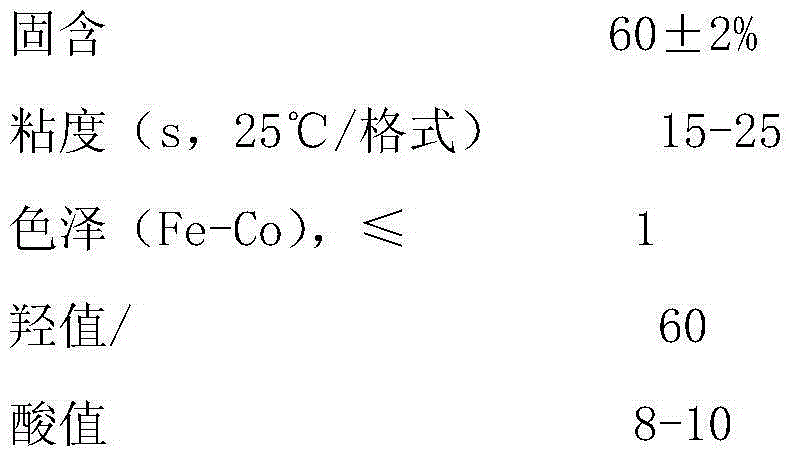

[0032] (3) Main indicators of LH-60 resin:

[0033]

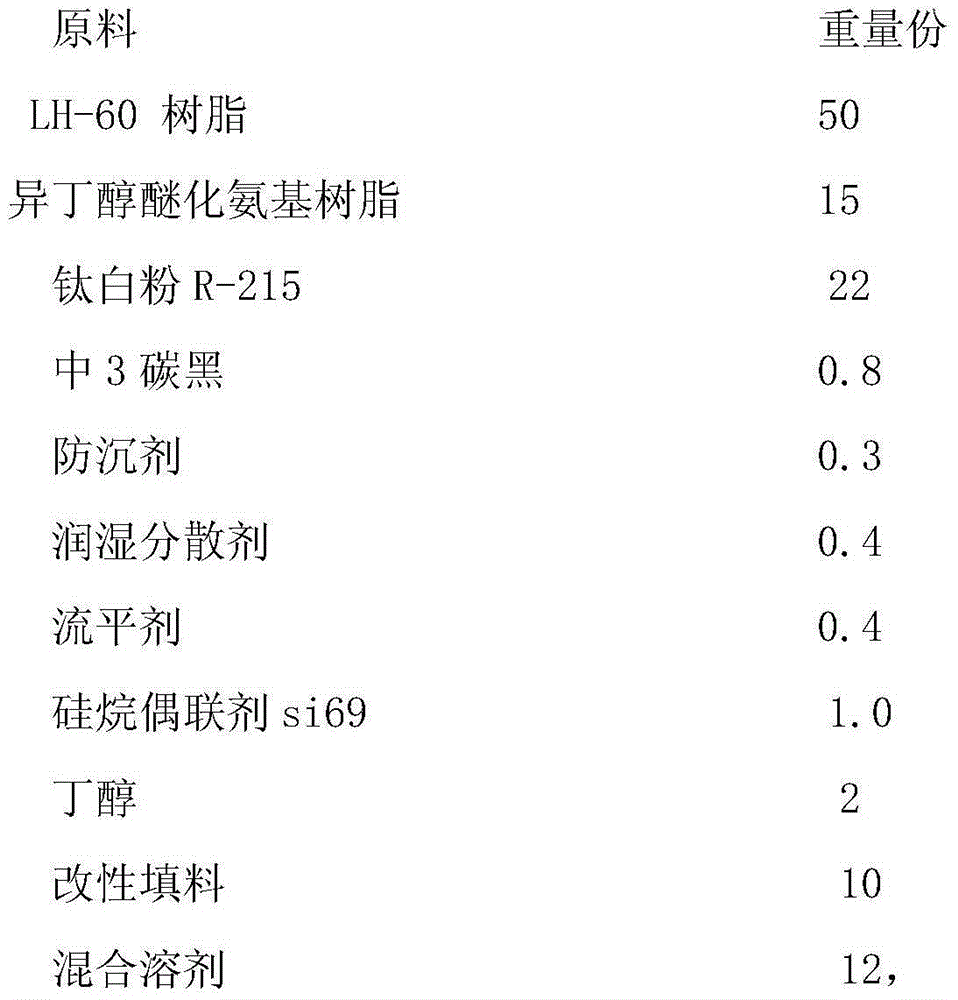

[0034] 2. Finished paint

[0035] (1) Formula composition

[0036]

[0037] The mixed solvent is formed by mixing xylene, ethylene gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com