Polyacrylate grafted modified polyester water-based coating and preparation method thereof

A technology of polyacrylate and graft modification, applied in the direction of coating, etc., can solve the problems of poor compatibility, poor comprehensive performance of cured paint film of compound coating, and low polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation of polyacrylate graft modified polyester water-based coating is carried out in three steps. The first step is to synthesize water-dispersed polyester resin, and the second step is to carry out solution graft copolymerization of water-dispersed polyester resin and acrylate monomer and styrene monomer to synthesize water-dispersed acrylate graft modified The third step is the preparation of water-based paint and its cured paint film.

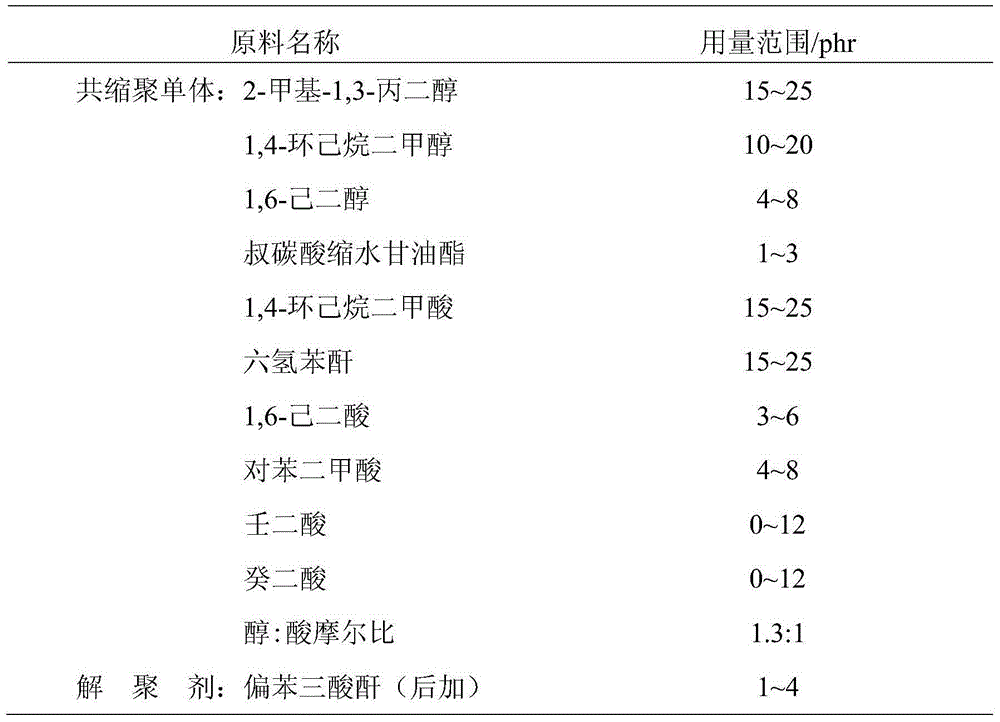

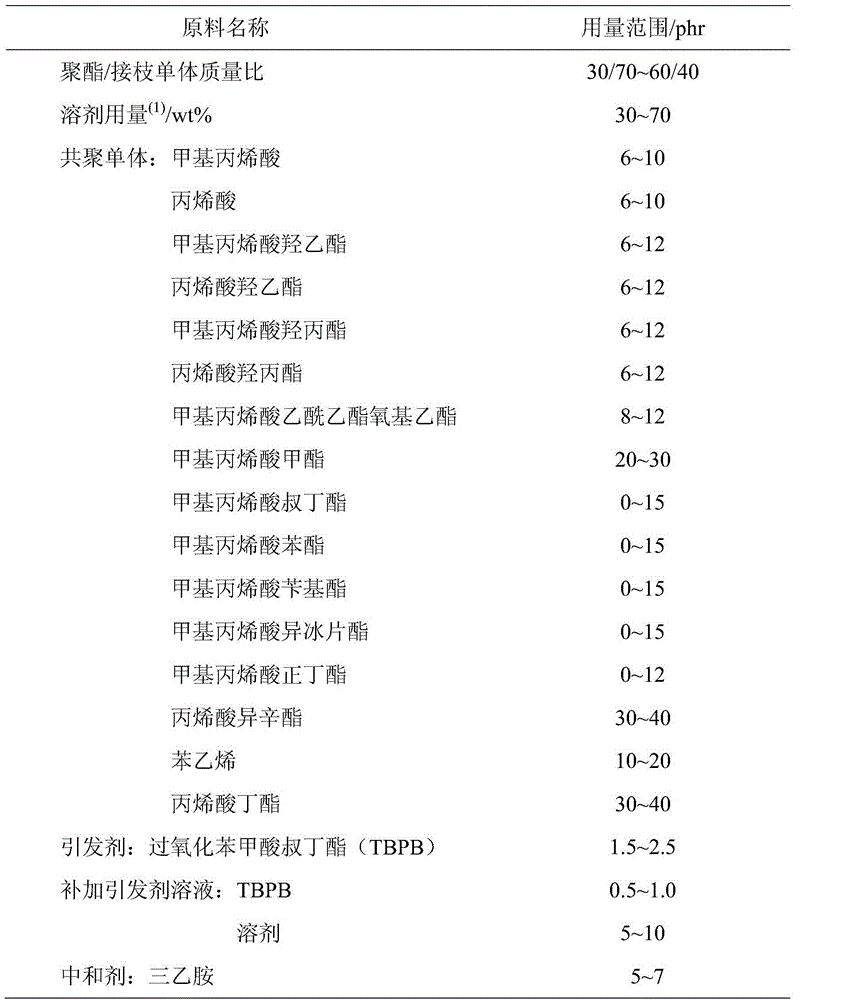

[0035] Table 1 is the names of raw materials used in the synthesis of water-dispersible polyester resins and their dosage ranges; Table 2 is the names of raw materials used in the synthesis of water-dispersible polyacrylate graft-modified polyester resins and their dosage ranges. Table 3 and Table 4 are the basic formulations of the synthetic water-dispersible polyester resin and the synthetic water-dispersible polyacrylate graft-modified polyester resin, respectively. Among the monomers used in the synthesis of water-dispe...

Embodiment 1

[0051] This embodiment is to provide in the stage of synthesizing water-dispersible polyester resin, the performance of the consumption of depolymerizing agent trimellitic anhydride to water-dispersible polyester resin, water-dispersible polyacrylate graft modified polyester resin and its water-based coating and curing effect on the properties of the paint film.

[0052] The preparation process of the water-dispersed polyacrylate graft-modified polyester water-based coating is carried out in three steps. The first step is to synthesize water-dispersed polyester resin, the second step is to synthesize water-dispersed polyacrylate graft-modified polyester resin, and the third step is to prepare water-based paint and its cured paint film.

[0053] Synthesis of the first water-dispersed polyester resin

[0054] The amount of the same monomer was fixed, and different amounts of depolymerization end-capping agent trimellitic anhydride were added in the late stage of the co-condensa...

Embodiment 2

[0075] This example is to provide the effect of the amount of glycidyl tertiary carbonic acid ester on the performance of water-dispersed polyacrylate graft modified polyester water-based paint and its cured paint film in the stage of synthesizing water-dispersed polyester resin.

[0076] Synthesis of the first water-dispersed polyester resin

[0077] Table 10 is the formula for synthesizing water-dispersible polyester under the condition of changing the amount of glycidyl tert-carbonic acid ester and keeping the amount of other similar monomers including trimellitic anhydride constant.

[0078] According to the formula ingredients in Table 10, carry out the co-condensation reaction according to the technical process of the first step of Example 1, and synthesize the water-dispersible polyester. It can be seen from Table 10 that when the amount of glycidyl tert-carbonate is in the range of 0-3.6%, the formed water-dispersed polyester resin has a uniform and transparent appeara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com