Epoxy adhesive for integral molding technology of electronic components and preparation method thereof

A technology for epoxy adhesives and electronic components, applied in the direction of in-line phenolic epoxy resin adhesives, epoxy resin adhesives, adhesives, etc., can solve the problems of reliability and the inability to meet the production process requirements of integrated inductors. , to achieve the effect of high bonding strength, high reliability and high Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Bisphenol A epoxy resin 30 parts

[0047] Biphenyl type epoxy resin 20 parts

[0048] Dicyandiamide 5 parts

[0049] imidazole 2 parts

[0050] 40 parts of N,N-dimethylformamide

[0051] Stabilizer 0.5 parts

[0052] Release agent 2.5 parts

[0053] Preparation:

[0054] Accurately weigh various raw materials according to the proportion of the formula, first add bisphenol A epoxy resin, biphenyl type epoxy resin, N,N-dimethylformamide, stabilizer, and mold release agent into the reaction kettle in turn and stir, wait until After stirring evenly, add dicyandiamide and imidazole, disperse evenly and discharge.

Embodiment 2

[0056] Bisphenol F epoxy resin 35 parts

[0057] Dicyclopentadiene type epoxy resin 15 parts

[0058] DDS 10 copies

[0059] imidazole 2 parts

[0060] 35 parts of N,N-dimethylformamide

[0061] Stabilizer 0.5 parts

[0062] Release agent 2.5 parts

[0063] Preparation:

[0064] Accurately weigh various raw materials according to the proportion of the formula, first add bisphenol F epoxy resin, dicyclopentadiene epoxy resin, N,N-dimethylformamide, stabilizer, and mold release agent into the reaction kettle and stir , after stirring evenly, add DDS and imidazole, disperse evenly and discharge.

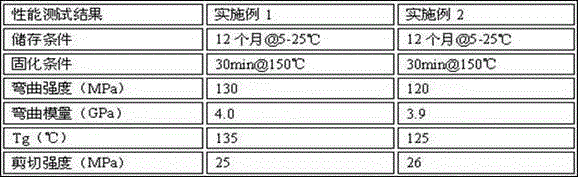

[0065] Examples listed in Table 1 and performance test results after curing thereof. The test results show that the epoxy adhesive of the present invention has high body strength, high modulus, high Tg, and high bonding strength, fully meets the requirements of the integral molding process, and has high reliability.

[0066] Table 1

[0067]

[0068] The present invention de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com