Full-rock roadway longitudinal shaft type heading machine

A technology of roadheader and rock roadway, which is applied in the field of vertical axis roadheader for all-rock roadway, can solve the problems of inconvenient assembly and disassembly, large daily footage, serious wear, etc., to achieve convenient assembly and disassembly, ensure production progress, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

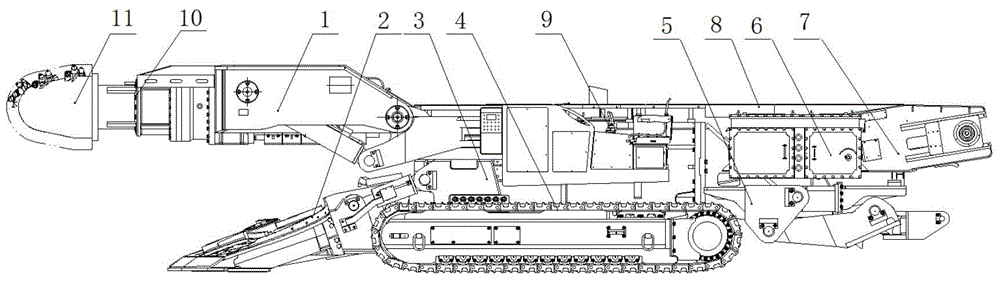

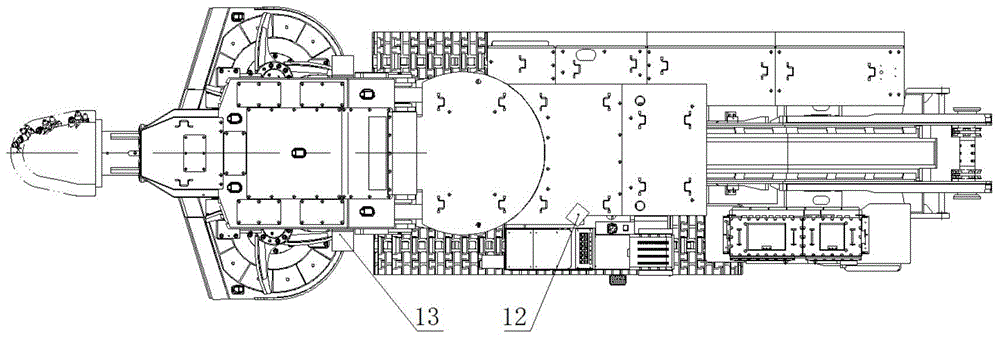

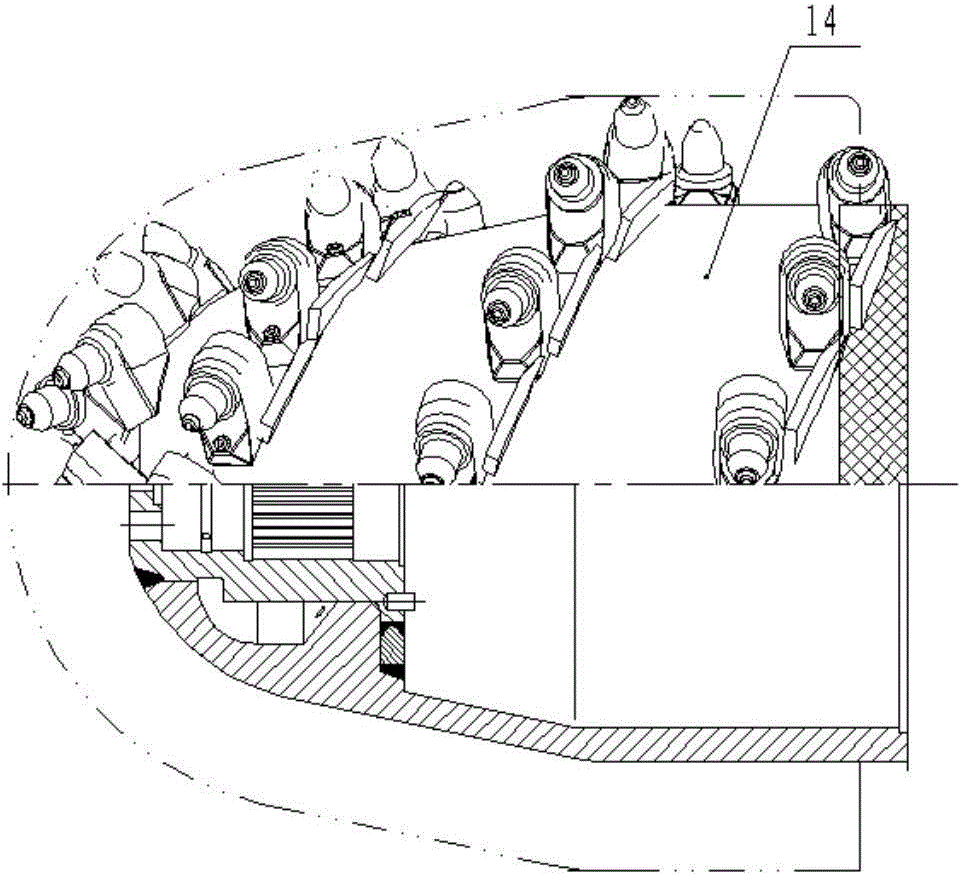

[0037] combine figure 1 , figure 2 , Figure 5 and Image 6 , a whole rock roadway longitudinal axis roadheader in this embodiment consists of a cutting part 1, a shovel part 2, a main frame 3, a walking part 4, a supporting part 5, an electrical system 6, a conveyor 7, a guard plate 8, The hydraulic system 9 and the water system 11 are composed of components such as the hydraulic system 9 and the water system 11. The cutting part 1 is located at the front and upper part of the main frame 3 and is connected with the main frame 3; 3; the shoveling part 2 is detachably connected to the main frame 3 through the first pin shaft 17, and the connection point is located at the front end of the walking part 4, which makes the shoveling board easy to assemble and disassemble, thereby reducing maintenance costs and maintenance cycles. The purpose of improving productivity; the right side of the main frame 3 is provided with a fuel tank in the hydraulic system 9; the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com