Testing apparatus and method for dry bulk density change of sediment deposit under large water pressure

A technology of sediment deposition and test device, which is applied in the field of test research of water conservancy and hydropower engineering, can solve problems such as difficulty in simulating large water pressure test conditions, and achieve the effect of important production and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

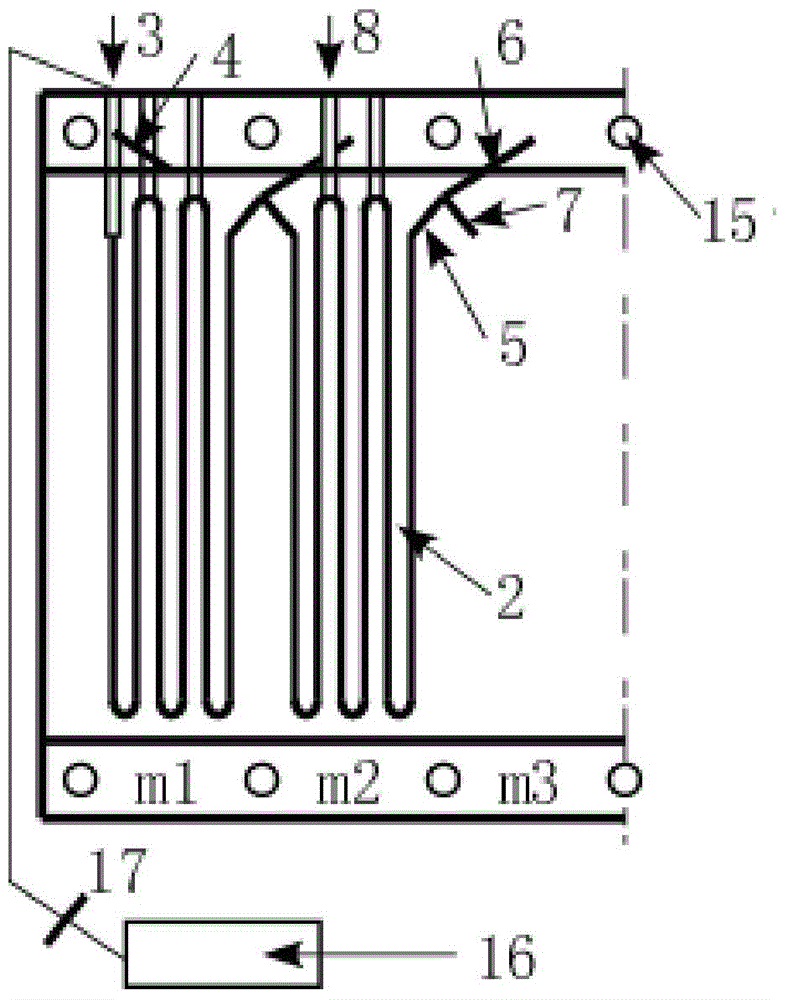

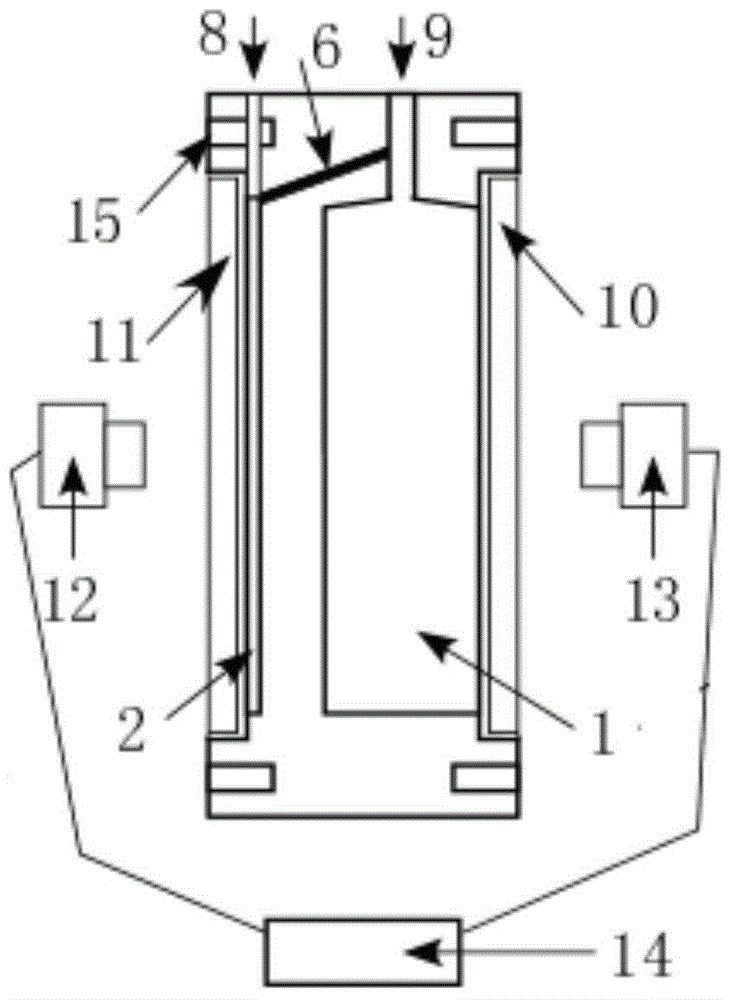

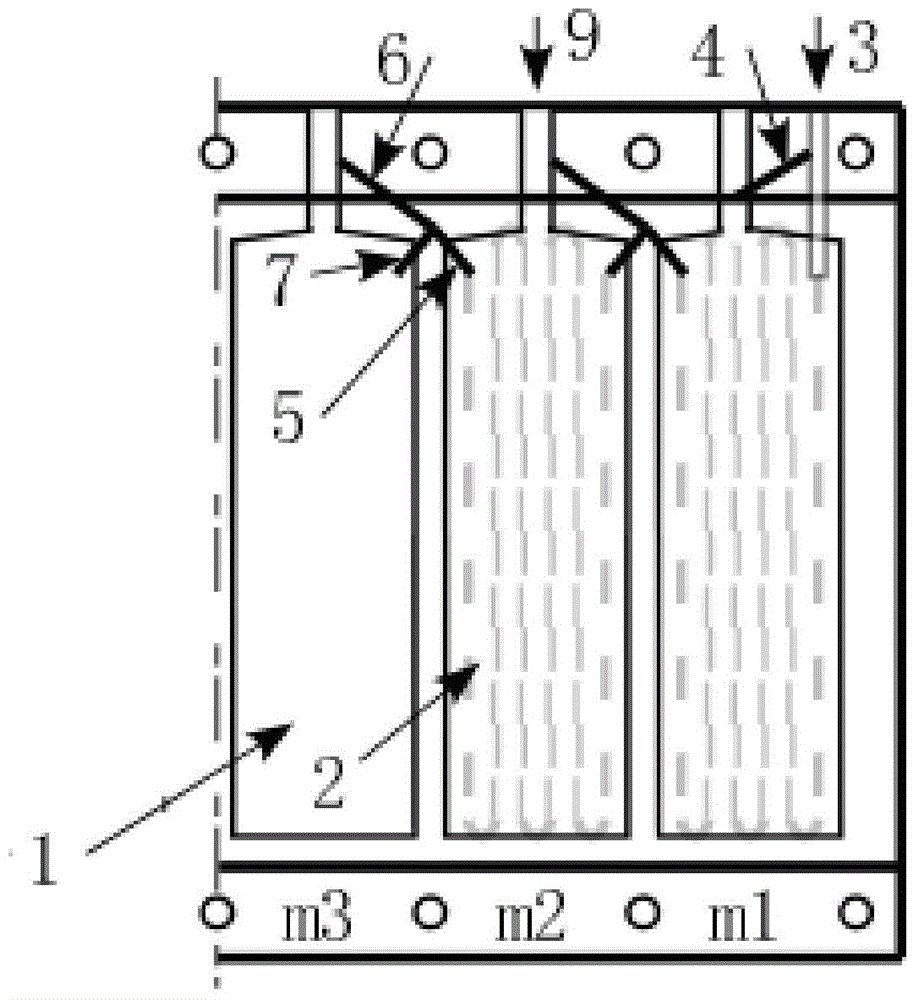

[0026] During specific implementation, a kind of test device for the change of dry bulk density of sediment deposits under high water pressure, its structure is shown in Figure 1- Figure 4 , Figure 1(a) for the back view, Figure 1(b) for the side view, Figure 1(c) For the front view. Figure 1(c) The dotted line of the two units on the right is the U-shaped pressurized tube 2 on the back, and m1, m2, m3...m10 in the figure are the test unit numbers. figure 2 It is a schematic diagram of the top plane of the shell.

[0027] The test device is mainly composed of a shell, a test cylinder, a U-shaped differential pressure tube, a pressurized tube, a connecting tube, a glass observation window, a camera, a computer and connected pressurized equipment. Among them, a plurality of U-shaped differential pressure pipes 2 form a group, and the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com