Deicing robot of high-voltage transmission lines

A high-voltage transmission line and robot technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve problems such as hidden dangers of power line operation, large vibration amplitude in the deicing process, large human and material resources, etc., and achieve data information collection. Accurate, comprehensive collection of data and information, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

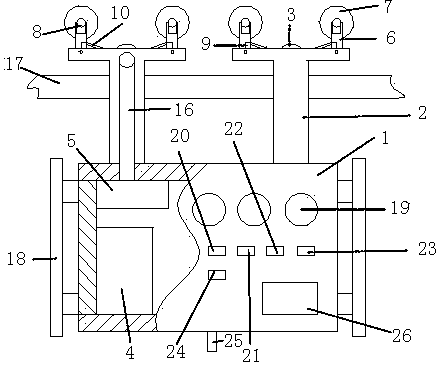

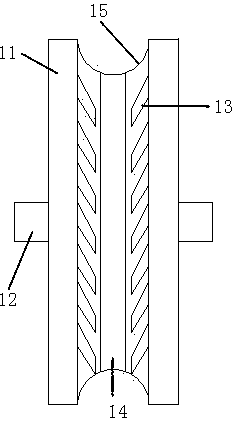

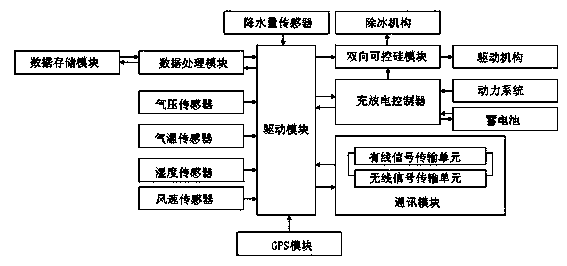

[0011] Such as figure 1 , 2 As shown in and 3, a high-voltage transmission line deicing robot, the deicing robot is composed of a tackle and a control system, the controller is placed inside the tackle, and the tackle is composed of a car body 1, a suspension arm 2, a pulley 3. The deicing mechanism, the power system, the storage battery 4 and the driving mechanism 5 are composed of at least two suspension walls 2 in a "T" shape structure, the ends of which are connected to the car body 1, and a pulley 3 is installed in the middle of the top, and the front and rear two A deicing mechanism is arranged on the side, and the deicing mechanism is hinged with the suspension wall 2. The described deicing mechanism is composed of a frame 6, a deicing wheel 7, a deicing driving mechanism 8 and a lifting driving mechanism 9. The described deicing wheel 7. Both the deicing driving mechanism 8 and the lifting driving mechanism 9 are installed on the frame 6, wherein the deicing driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com