Black garlic as well as fermentation process thereof

A fermentation process and technology of black garlic, applied in the field of food deep processing, can solve the problems of easily damaged nutrients, long fermentation cycle of black garlic, complicated operation process, etc., achieve scientific and reasonable fermentation time and temperature, shorten fermentation cycle, and speed up the reaction The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

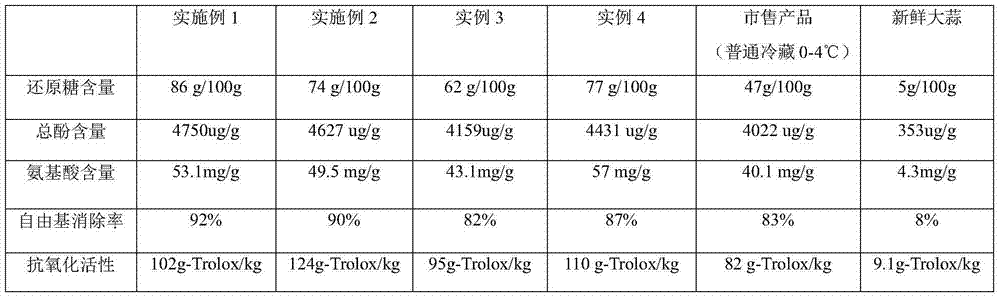

Examples

Embodiment 1

[0030] A kind of black garlic fermentation technology, comprises the following steps:

[0031] (1) Freeze the fresh garlic cloves at a freezing temperature of -22°C and a freezing time of 10 hours;

[0032] (2) Thaw the garlic cloves frozen in step (1) naturally, put them into a breathable polyethylene bag, seal the bag, and place it in a water bath with constant temperature;

[0033] (3) Fermentation is divided into two stages: the first stage fermentation temperature is 35°C, constant temperature fermentation for 10 days, the second stage fermentation temperature is 90°C, constant temperature fermentation for 4 days;

[0034] (4) After the fermentation, the black garlic was taken out from the bag and dried at a temperature of 40°C for 25 hours to obtain a finished black garlic product.

Embodiment 2

[0036] (1) Freeze the fresh garlic cloves at a freezing temperature of -22°C and a freezing time of 10 hours;

[0037] (2) Thaw the garlic cloves frozen in step (1) naturally, put them into a breathable polyethylene bag, seal the bag, and place it in a water bath with constant temperature;

[0038] (3) Fermentation is divided into two stages: the first stage fermentation temperature is 40°C, constant temperature fermentation for 4 days, the second stage fermentation temperature is 90°C, constant temperature fermentation for 10 days;

[0039] (4) After the fermentation, the black garlic was taken out from the bag and dried at a temperature of 40°C for 25 hours to obtain a finished black garlic product.

Embodiment 3

[0041] (1) Freeze the fresh garlic cloves at a freezing temperature of -40°C and a freezing time of 10 hours;

[0042] (2) Thaw the frozen garlic in step (1) naturally, put it into a breathable polyethylene bag, seal the bag, and place it in a water bath with constant temperature;

[0043] (3) Fermentation is divided into two stages: the first stage fermentation temperature is 40°C, constant temperature fermentation for 4 days, the second stage fermentation temperature is 90°C, constant temperature fermentation for 10 days;

[0044] (4) After the fermentation, the black garlic was taken out from the bag and dried at a temperature of 70°C for 6 hours to obtain a finished black garlic product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com