Drying agent

A desiccant, polyacrylamide technology, applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as damage to items, and achieve the effects of long effective time, low cost of raw materials, and high moisture absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

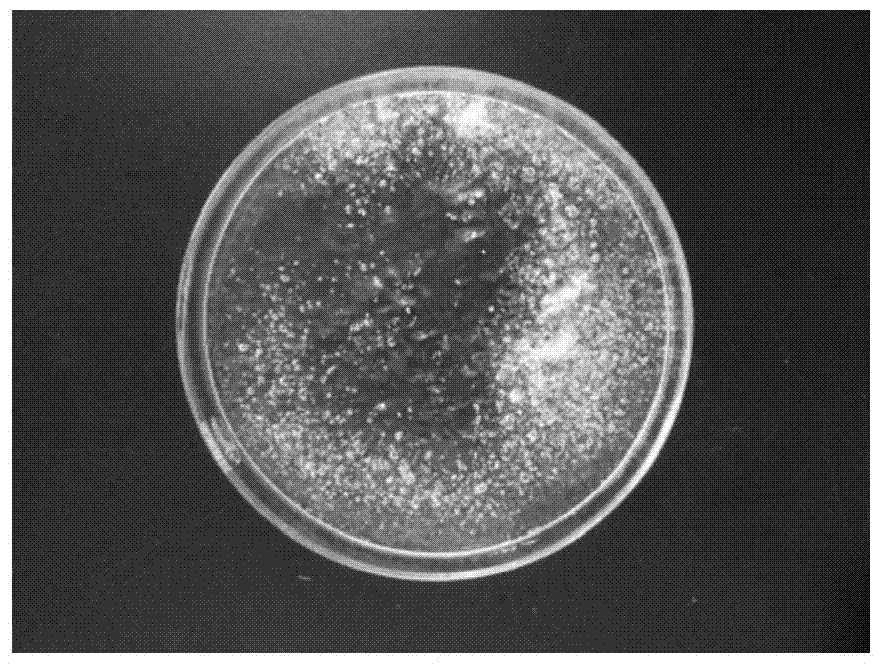

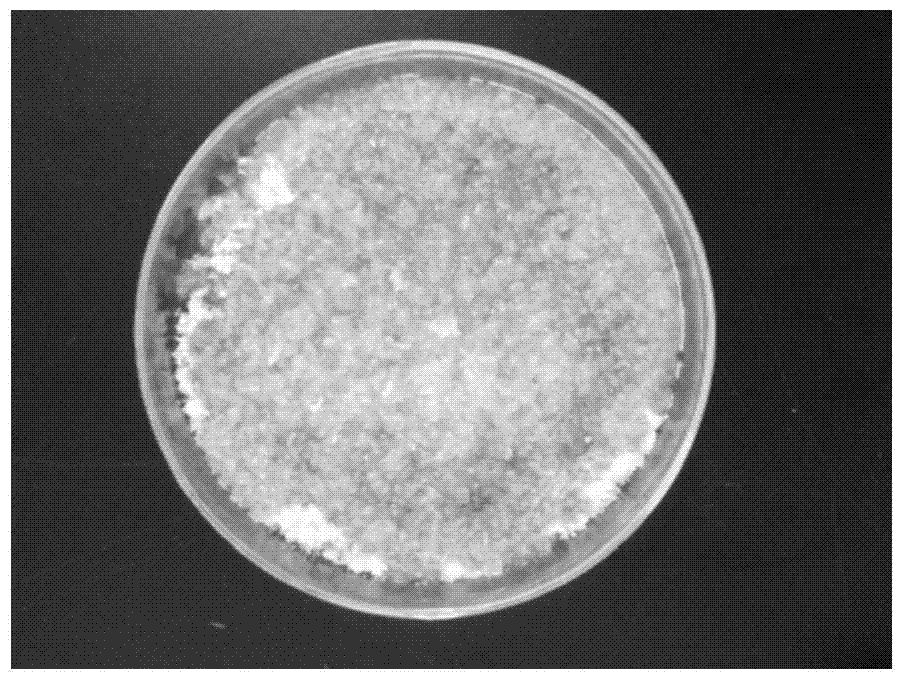

Image

Examples

Embodiment 1

[0018] Example 1 Container high moisture absorption desiccant

[0019] According to the application field, the adsorbent is anhydrous calcium chloride, the water-absorbent polymer is polyacrylamide with a polymerization measurement of 18 million, and the ion substitution degree is 40%.

[0020] According to the technical requirements, the moisture absorption capacity is greater than 280% under the conditions of 25°C and 90% relative humidity. Choose 2 parts of anhydrous calcium chloride and 1 part of polyacrylamide, mixed to prepare a high moisture absorption desiccant mixed adsorbent.

[0021] The moisture absorption performance comparison between the desiccant of this embodiment and the traditional high-hygroscopic desiccant (test conditions, 25° C., RH 90%, the sample is a bare sample) is shown in Table 1.

[0022] Table 1: Comparison of moisture absorption performance

[0023] Moisture absorption time (hr)

[0024] 12

[0025] The desiccant was left for one month, and no liqui...

Embodiment 2

[0027] According to the application field, the adsorbent is anhydrous calcium chloride, the water-absorbent polymer is polyacrylamide with a polymerization measurement of 18 million, and the ion substitution degree is 40%. 4 parts of anhydrous calcium chloride; 1 part of polyacrylamide, 0.1 part of vegetable starch (cured corn starch), mixed to prepare a high moisture absorption desiccant mixed adsorbent.

[0028] The moisture absorption performance comparison between the desiccant of this embodiment and the traditional high-hygroscopic desiccant (test conditions, 25° C., RH 90%, the sample is a bare sample) is shown in Table 2.

[0029] Table 2: Comparison of moisture absorption performance

[0030] Moisture absorption time (hr)

[0031] The desiccant was left for one month, and no liquid water seeped out. The traditional high-hygroscopic desiccant has water analysis.

Embodiment 3

[0033] The water-absorbent polymer is polyacrylamide with a polymerization measurement of 18 million and an ion substitution degree of 40%. 2 parts of anhydrous calcium chloride, 3 parts of calcium chloride dihydrate, 1 part of polyacrylamide, 0.3 parts of plant lake (cured potato starch), the four are mixed to prepare a high-hygroscopic desiccant mixed adsorbent.

[0034] The moisture absorption performance comparison between the desiccant of this embodiment and the traditional high-hygroscopic desiccant (test condition, 25°C, RH90%, the sample is a bare sample) is shown in Table 3.

[0035] Table 3: Comparison of moisture absorption performance

[0036] Moisture absorption time (hr)

[0037] The desiccant was left for one month, and no liquid water seeped out. The traditional high-hygroscopic desiccant has water analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com