Method for crystallizing large-grained industrial ammonium dihydrogen phosphate

An industrial-grade monoammonium phosphate technology, which is applied in the direction of phosphate, phosphorus oxyacids, etc., to achieve the effect of improving the product's easy agglomeration, large particle size, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Wet process phosphoric acid pretreatment

[0024] Take wet-process phosphoric acid and place it in a three-necked flask, add potassium carbonate and phosphate rock powder, where in molar ratio, wet-process phosphoric acid: potassium carbonate: phosphate rock powder=1:1.2:1.5, cover the bottle stopper, and place in a constant temperature water bath , the reaction temperature is 90°C, the stirring speed is 200r / min, the reaction time is 3h, and filtered; the filtrate is placed in a reaction vessel, and barium carbonate is added, wherein in terms of molar ratio, wet-process phosphoric acid: barium carbonate=1:1.1, Cover the bottle with a stopper, place it in a constant temperature water bath at 50°C, control the stirring speed to 200r / min, react with suction for 60min, and filter with suction. The filtrate is the pretreatment solution of wet-process phosphoric acid.

[0025] 2. Preparation of neutralizing solution

[0026] Weigh a certain amount of wet-process phosphor...

Embodiment 2

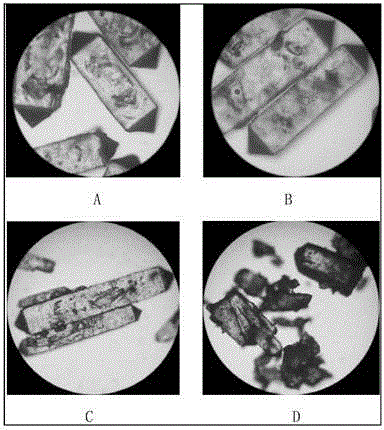

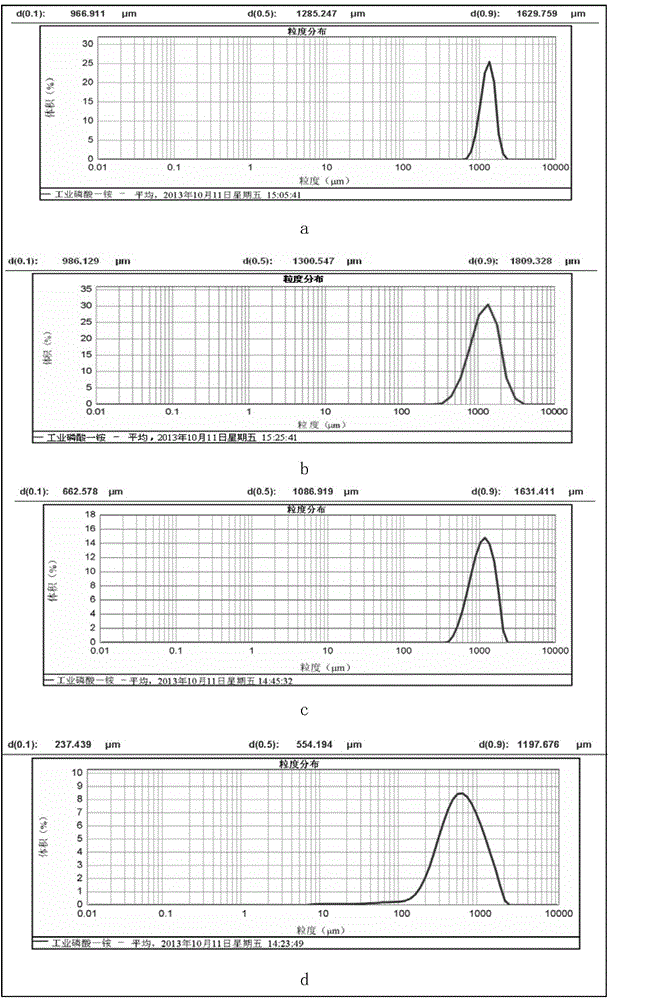

[0030] The preparation of wet-process phosphoric acid pretreatment and neutralizing liquid is as described in Example 1, and the density of neutralizing liquid of the present invention is concentrated to 1.36g / cm 3 , the concentrated solution was cooled and crystallized, and the temperature was lowered to 44°C under the conditions of a rotation speed of 270r / min and a temperature drop gradient of 0.1°C / min. Obtain 68.80 g of industrial grade monoammonium phosphate, with a purity of 98.24%. The product is a white crystal that is more uniform than industrial products, and the particle size distribution is too wide.

Embodiment 3

[0032] The preparation of wet-process phosphoric acid pretreatment and neutralizing liquid is as described in Example 1, and the density of neutralizing liquid of the present invention is concentrated to 1.37g / cm 3 , the concentrated solution was cooled and crystallized, and the temperature was lowered to 43°C under the conditions of a rotation speed of 280rmp and a temperature drop gradient of 0.5°C / min. Obtain 81.19g of industrial grade monoammonium phosphate with a purity of 98.53%. The product is a relatively uniform white crystal with an average surface area particle size of 1119.241 μm, a volume average particle size of 998.051 μm, and an average particle size of 1086.919 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com