Flame-retardant epoxy floor coating and preparation method thereof

A technology of epoxy flooring and coatings, which is applied in the direction of epoxy resin coatings, fireproof coatings, coatings, etc., can solve the problems of low temperature resistance, pungent nose, etc., and achieve the effect of easy operation, convenient construction, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

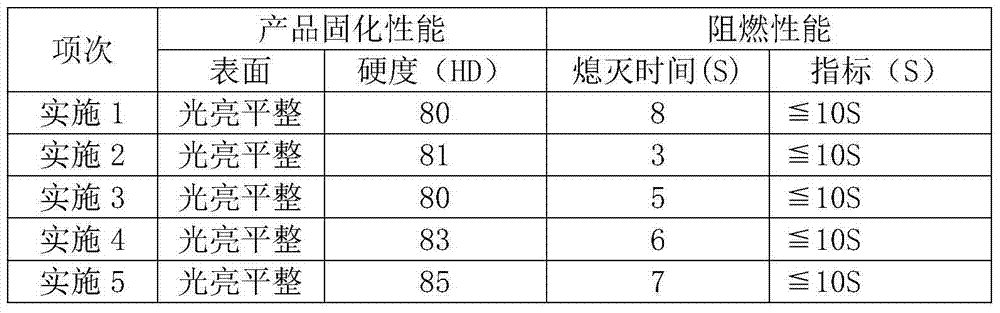

Examples

Embodiment 1

[0028] Parts by weight:

[0029] Main ingredient:

[0030] E-51 40 copies,

[0031] AGE 2 servings,

[0032] 20 parts of tetrabromobisphenol A,

[0033] 30 parts of antimony trioxide,

[0034] BYK-525 0.01 parts,

[0035] BYK-111 2 copies,

[0036] BYK-320 0.01 parts,

[0037] 1 part green agent,

[0038] Curing agent: D-230 30 parts, IPAD modification 10 parts, DMP-30 10 parts.

[0039] Mix and cure the main agent and curing agent according to the weight ratio of 100:20, make 3 samples with a thickness of 3 mm, a width of 13 mm, and a length of 125 mm. The samples are placed vertically and installed; when installing, the lower end of the sample is kept away from the burning Put a blue flame with a height of 3 / 4" on the center of the lower end of the sample at the top 3 / 8" of the tube, burn it for 10 seconds, then remove the flame and extinguish it for 8 seconds to make a flame-retardant epoxy floor coating.

Embodiment 2

[0041] Parts by weight:

[0042] Main agent:

[0043] E-51 40 copies,

[0044] E-44 30 copies,

[0045] BGE 10 parts,

[0046] 15 parts of ammonium polyphosphate, 15 parts of aluminum hydroxide,

[0047] BYK-A530 2 copies,

[0048] BYK-110 0.01 parts,

[0049] BYK-315 2 parts,

[0050] Gray agent 5 parts,

[0051] Hardener:

[0052] D-230 90 copies,

[0053] 70 parts of MXDA modified amine,

[0054] 1 part of triethylamine.

[0055] Mix and cure the main agent and curing agent according to the ratio (weight ratio) of 100:30, and make 3 samples with a thickness of 3 mm, a width of 13 mm, and a length of 125 mm. The samples are placed vertically and installed; when installing, make the lower end of the sample 3 / 8" away from the top of the combustion tube, place a blue flame with a height of 3 / 4" in the center of the lower end of the sample, burn for 10 seconds, then remove the flame and extinguish for 5 seconds to make a flame-retardant epoxy floor coating.

Embodiment 3

[0057] Parts by weight:

[0058] Main ingredient: 38 parts of E-51, 7 parts of E-20,

[0059] 4 parts of benzyl alcohol, 5 parts of isobutanol,

[0060] 15 parts of antimony trioxide, 20 parts of aluminum hydroxide, 5 parts of ammonium chloride, 5 parts of boric acid,

[0061] BYK-A530 0.3 parts,

[0062] BYK-110 0.2 parts,

[0063] BYK-315 0.02 parts,

[0064] 1.48 parts of green agent,

[0065] Curing agent: 45 parts of D-230, 50 parts of MXDA modified amine, 5 parts of K-54,

[0066] Mix and cure the main agent and curing agent according to the ratio (weight ratio) of 100:25, and make 3 samples with a thickness of 3 mm, a width of 13 mm, and a length of 125 mm. The samples are placed vertically and installed; when installing, make the lower end of the sample 3 / 8" from the top of the combustion tube, place a blue flame with a height of 3 / 4" in the center of the lower end of the sample, burn for 10 seconds, then remove the flame and extinguish for 3 seconds to make a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com