Electric-working abdicating and unloading linkage permanent-magnet-drive vertical type pumping unit

A permanent magnet drive, pumping unit technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of high failure rate of rigid couplings, unloading and hanging pumping is not easy to achieve, and the driving rope is easy to slip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

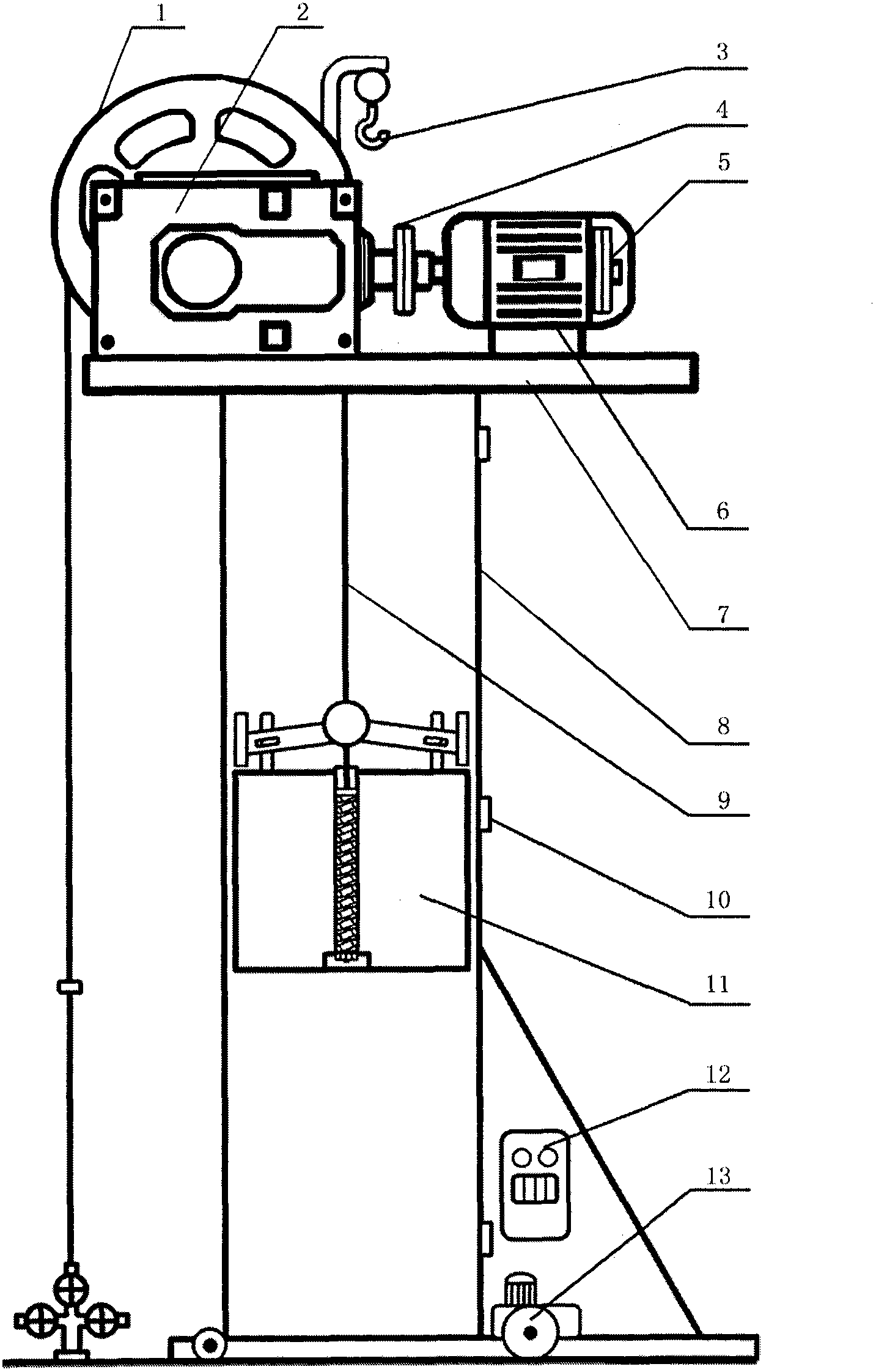

[0040] Such as figure 1 Shown: the permanent magnet drive vertical pumping unit of the present invention with electric operation step-off and unloading linkage linkage includes the frame (8) and the top of the frame (8) which are moved by the electric operation step-off device (13) on the frame base. On the platform (7), the driving device that connects the motor (6) with electromagnetic brake (5), the reducer (2), and the driving wheel (1) in series by the permanent magnetic coupling (4), and the auxiliary device for unloading and pulling out (3) and the intelligent controller (12) installed in the control cabinet at the lower part of the frame (8) by the sensor (10) to control the stroke, wherein the driving wheel (1) is hung in the rope groove on both sides of the axial direction to hang the sucker rod , the other end is suspended with a drive rope (9) with a counterweight (11) for the anti-fall device, and the drive wheel (1) is fixed in the rope groove in the middle of th...

Embodiment 2

[0056] Such as figure 1 Shown: the main body structure of the permanent magnet drive vertical pumping unit of the present invention is the same as that of embodiment 1, and only the following transmission mechanism has been improved:

[0057] The driving wheel (1) is covered with a strong fiber belt in the rope groove on both sides of the axial direction, and the sucker rod is suspended at one end of the strong fiber belt, and the anti-falling device balance weight (11) is suspended at the other end; the driving wheel (1) shaft Fix the loss of load protection and anti-skid strong fiber belt one end in the rope groove in the middle part, and the other end is connected with the anti-falling device balance weight (11).

[0058] The permanent magnet coupling (4) is a wheel type radial synchronous permanent magnet coupling in which permanent magnets are alternately densely or dispersedly arranged on the surface of the driven rotor according to N and S polarity symmetry.

[0059] T...

Embodiment 3

[0069] Such as figure 1 Shown: the main body structure of the permanent magnet drive vertical pumping unit of the present invention is the same as that of embodiment 1, only the following transmission structure has been improved:

[0070] One end of the drive rope (9) is fixed in the rope groove on both sides of the drive wheel (1) axially, and the sucker rod is suspended at the other end; one end of the drive rope (9) is fixed in the rope groove in the middle of the drive wheel (1), One end is suspended with a counterweight (11) with a fall arrester.

[0071] The permanent magnet coupling (4) is to change the surface of the driven rotor into a copper ring, and rely on the rotation of the permanent magnet active rotor to make the copper ring on the driven rotor cut the magnetic force lines to generate an eddy current magnetic field and transfer the eddy current slip of the torque permanent magnet coupling

[0072] The fixed end of the electromagnetic brake (5) is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com