Multifunctional composite natural cellulose brucite powder material and its modified material and composite mother granules manufacturing method

A natural fiber and composite powder technology, which is applied in the direction of fibrous fillers, chemical instruments and methods, botanical equipment and methods, etc., can solve the problems of unsightly appearance and color, lack of tensile strength, energy consumption, high cost, etc. , to achieve remarkable bactericidal effect, wide application range and low cost

Inactive Publication Date: 2004-04-21

SIWOTE SCI & TECH MIANYANG CITY

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The reinforcing effect of glass fiber is also quite remarkable, the mechanical properties are almost the same as those of aramid fiber, and it has good flame resistance, formability, aging resistance, yellowing, strong adhesion, good tensile strength and friction resistance, but the cost is high. Complex production process, easy to bend, poor mechanical properties

Reinforcing material with mica as raw material, excellent electrical properties (high strength, insulation resistance, low dielectric loss, corona resistance), excellent mechanical properties, and good heat resistance, moisture resistance, chemical stability and high-energy radiation resistance , but the production cost is high, the viscosity and toughness are poor, and it is not wear-resistant

Other mineral reinforcing materials represented by carbon black have the advantages of better reinforcement, wear resistance and anti-aging performance, but high energy consumption and cost, no tensile strength, easy deformation, and unattractive appearance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

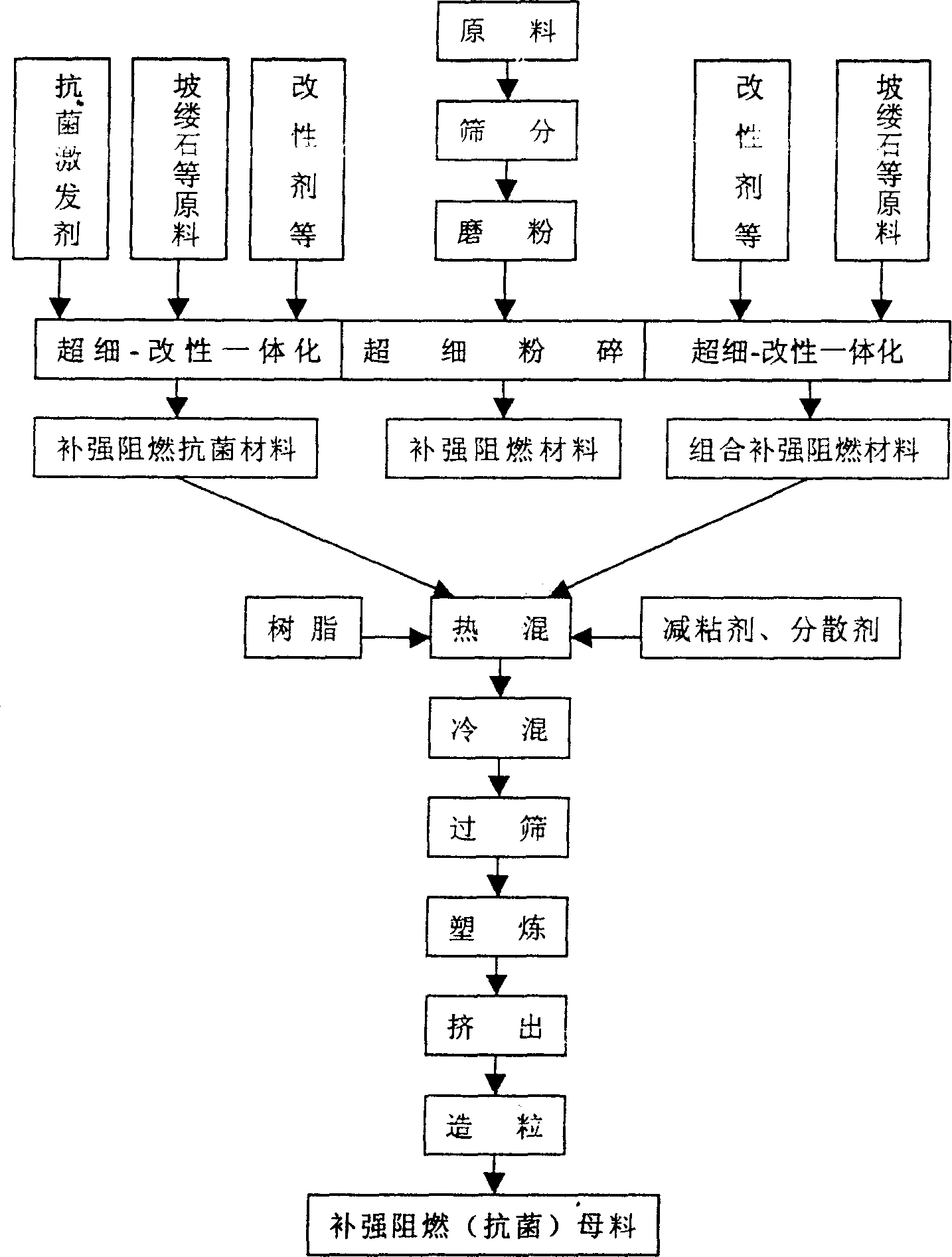

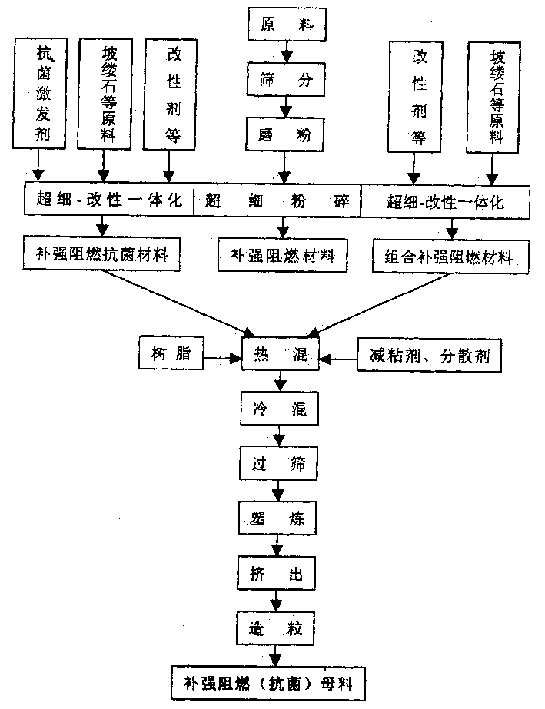

[0011] In the present invention, the method of using natural fiber brucite as raw material to prepare multifunctional composite powder material is relatively simple, which has been mentioned above. The method for further producing modified materials and composite masterbatches will be described in detail below.

[0012] Example

[0013] Example

[0014] Example

[0015] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

A multifunctional composite powder of natural fibres and brucite, its modifier and the process for preparing its composite mother particles are disclosed. Said flame-retarding, antibacterial and reinforcing composite powder is prepared through superfine pulverizing for brucite, suspension atomizing of modifier, and directional loosening. Its modifier is composed of coupling agent and antibacterial trigger. The process for preparing said mother particles includes mixing modifier, antibacterial material, high-molecular organic polymer and viscosity decreaser, plasticizing, extruding out and cutting to become particles.

Description

[0001] (1) Technical field: the present invention relates to a kind of method that takes natural fiber brucite as raw material to prepare multifunctional composite powder material and its modified material and composite masterbatch, which belongs to the technical field of magnesium compounds. (two) background technology: [0002] 1) Flame retardant material Background technology: There are two types of flame retardant materials, one is inorganic flame retardant material, and the other is organic flame retardant material. Inorganic flame retardant materials generally have the disadvantage of decomposing at low temperature, such as aluminum hydroxide and antimony chloride, aluminum hydroxide is easy to decompose at low temperature, and antimony chloride is toxic and expensive. However, organic flame-retardant materials such as groups containing chlorine, phosphorus, and bromine have the disadvantages of being toxic, easy to decompose, easy to age, and high in cost. Therefore, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01N25/08C08K9/08C08L101/00C09C3/00

Inventor 董发勤张宝述袁昌来

Owner SIWOTE SCI & TECH MIANYANG CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com