Frozen buckwheat bean curd skin and production method thereof

A technology of buckwheat bean curd and bean curd, which is applied in the field of frozen buckwheat bean curd and its production, can solve the problems affecting the edible quality of bean curd, the product is not resistant to boiling, and the bean curd is broken, so as to avoid the interference of bad weather factors and overcome Effects of starch aging and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

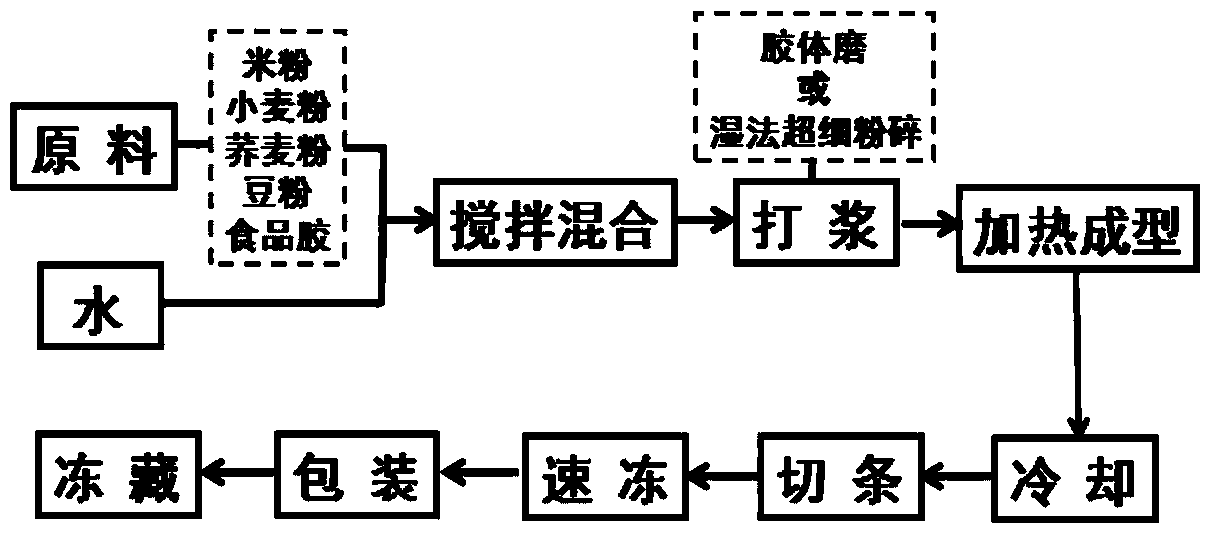

[0039] Weigh 30kg80 purpose early rice flour, 45kg80 purpose wheat flour, 20kg80 purpose sweet buckwheat flour, 5kg80 purpose mung bean powder, 0.15kg konjac powder, 0.05kg soybean polysaccharide, according to figure 1 The production process is to add 130kg of water, grind it into a paste-like slurry with a particle size of 200-300 mesh through a wet ultra-fine pulverizer, let it stand for 15 minutes, and skim off the surface foam; pour the evenly stirred slurry on a flat-bottomed heating plate on the Spread pancakes at 180°C into 1-2mm thick pancakes; after fully cooling, cut into strips with a width of 1cm by a strip cutter; freeze the sliced bean curds in a freezer at -35°C for 15 minutes to keep the center temperature of the bean curds reach -15°C; the quick-frozen bean curds are packed with low moisture permeability barrier materials at an ambient temperature not higher than 5°C; the packed bean curds are stored in a freezer at -18°C to obtain The frozen buckwheat bean ...

Embodiment 2

[0049] Weigh 45kg80 purpose late rice flour, 35kg80 purpose wheat flour, 17.5kg80 purpose tartary buckwheat flour, 2.5kg80 purpose red bean powder, 0.03kg konjac fine powder, 0.02kg soybean polysaccharide, according to figure 1 The production process is to add 150kg of water, pass through a colloid mill and grind it into a paste-like slurry with a particle size of 200-300 mesh, let it stand for 30 minutes, and skim off the surface foam; pour the evenly stirred slurry on a flat-bottomed heating plate and spread it at 150°C. Pancakes with a thickness of 1-2mm; after fully cooling, cut into strips with a width of 1.5cm by a strip cutter; put the sliced bean curds in a freezer at -30°C for 20 minutes to make the center temperature of the bean curds reach -18 ℃; the quick-frozen bean curds are packed with low moisture permeability barrier materials at an ambient temperature not higher than 5°C; the packed bean curds are frozen in a freezer at -20°C to obtain the present invention....

Embodiment 3

[0053] Weigh 50kg80 purpose early rice flour, 25kg80 purpose wheat flour, 15kg80 purpose sweet buckwheat flour, 10kg80 purpose soybean powder, 0.15kg konjac powder, 0.35kg soybean polysaccharide, according to figure 1 In the production process, add 180kg of water, grind it into a paste slurry with a particle size of 200-300 mesh through a wet ultrafine pulverizer, let it stand for 30 minutes, and remove the surface foam; pour the uniformly stirred slurry on a flat-bottomed heating plate at 200 ℃ into pancakes with a thickness of 1-2mm; after fully cooling, cut into strips with a width of 1.5cm by a strip cutter; put the sliced bean curds in a freezer at -30°C for 30 minutes to make the center temperature of the bean curds reach -20°C; the quick-frozen bean curds are packed with low moisture permeability barrier materials at an ambient temperature not higher than 5°C; the packed bean curds are stored in a freezer at -18°C to obtain this The invention provides the frozen buckw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com