Solenoid valve

A solenoid valve and magnetic core technology, applied in the field of solenoid valves, can solve problems such as difficult manufacturing and complex structure, and achieve the effects of reducing manufacturing costs, improving work reliability, and excellent responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail with reference to the accompanying drawings. Hereinafter, in describing the embodiments of the present invention, and in attaching reference numerals to components, the same components are denoted by the same reference numerals as much as possible even if they are shown in different drawings.

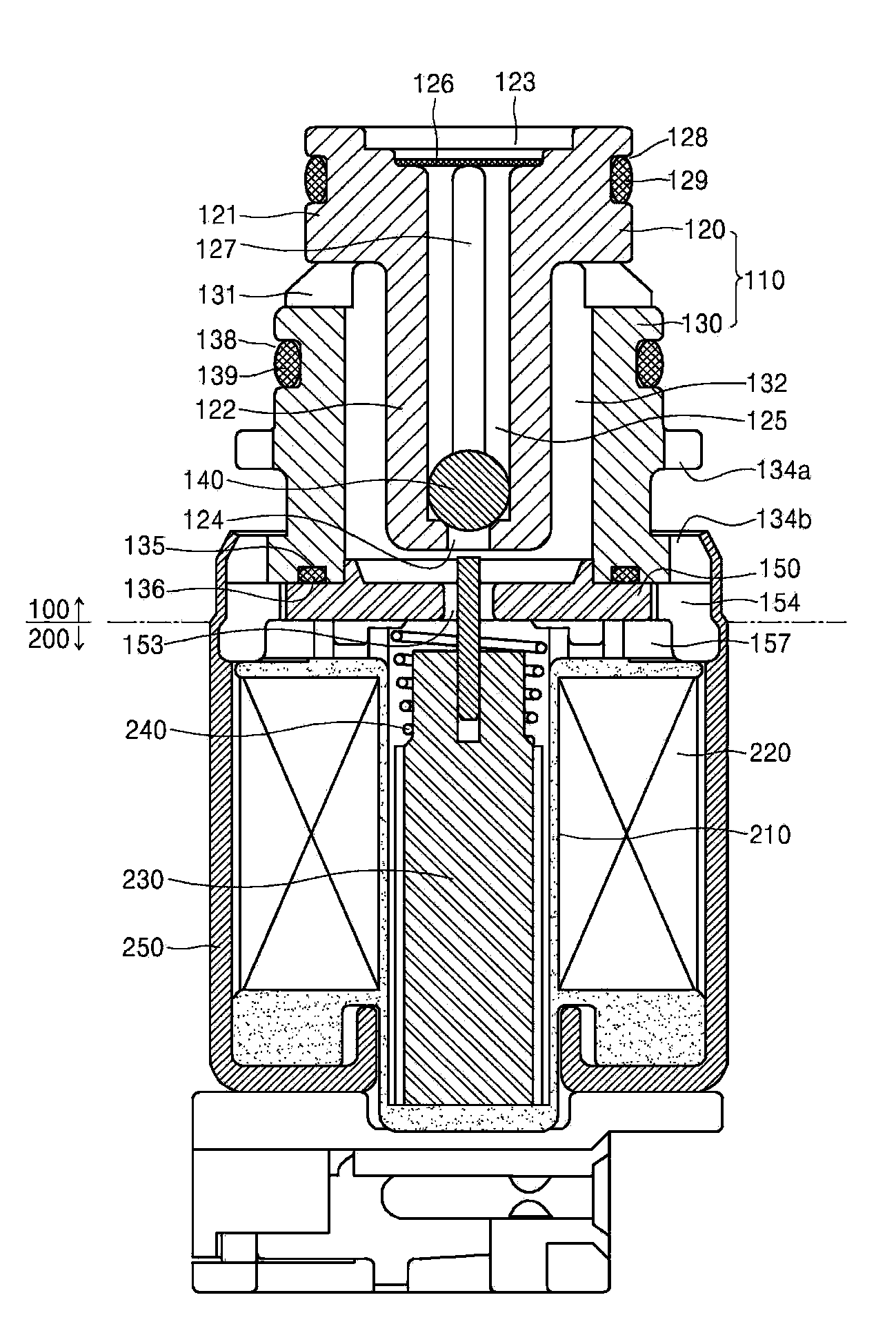

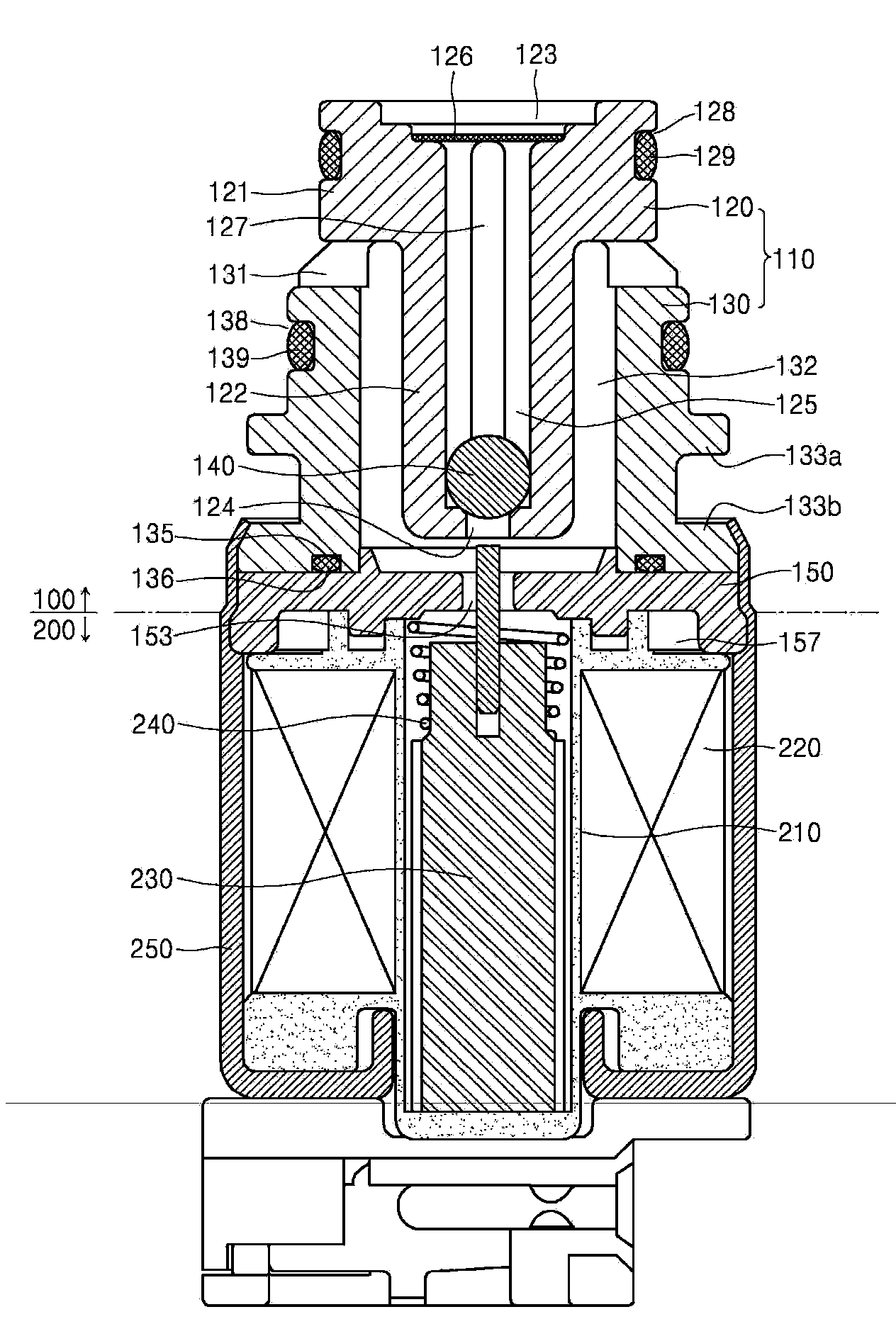

[0032] A solenoid valve according to an embodiment of the present invention includes a valve 100 for controlling the flow of fluid and a solenoid 200 for operating the valve 100 .

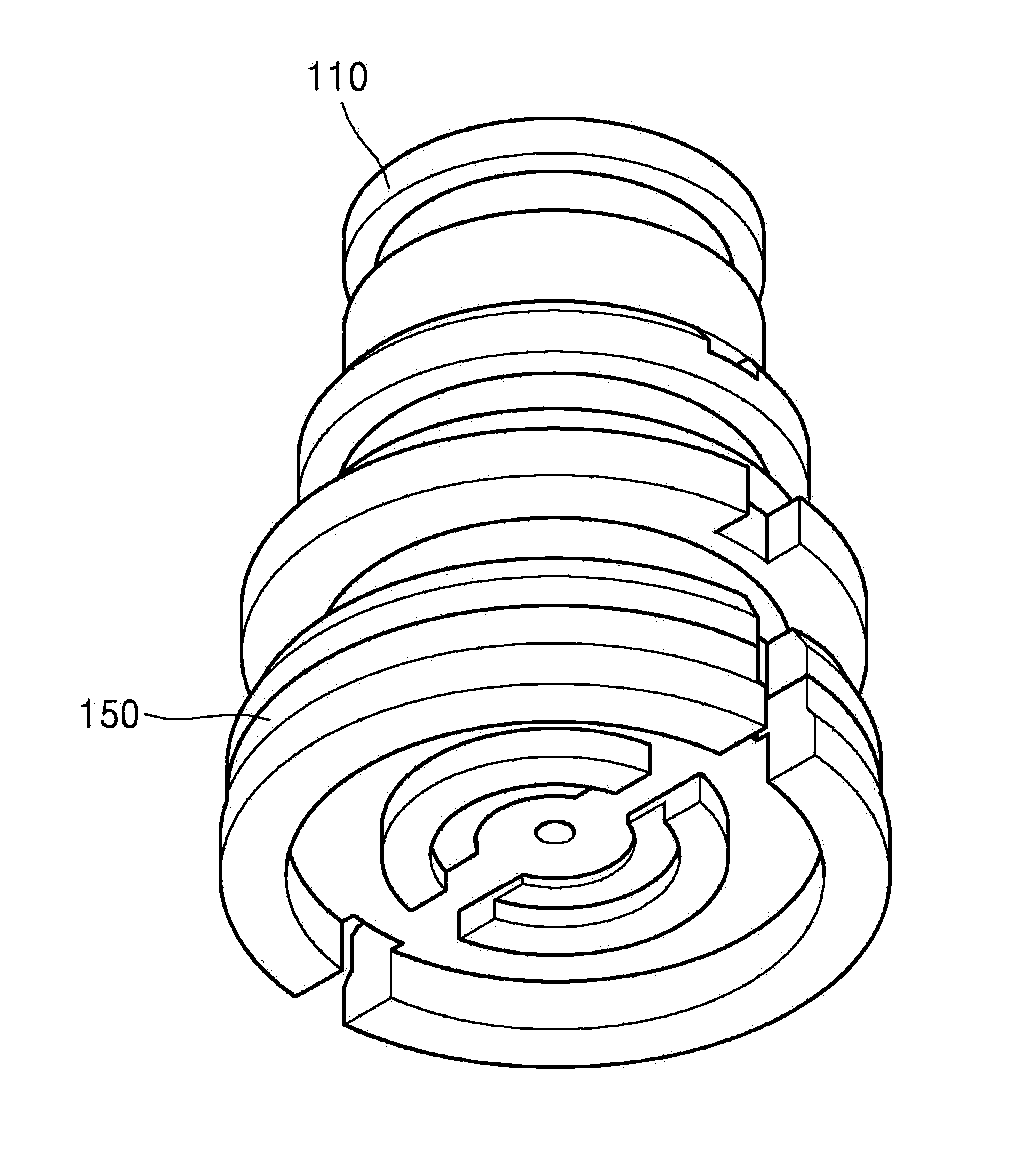

[0033] like figure 1 and figure 2 As shown, the valve 100 includes: a bracket 110 ; a ball 140 arranged inside the bracket 110 ; a magnetic core 150 combined with the lower end of the bracket 110 ;

[0034] The stent 110 is a double tube structure composed of an inner tube 120 and an outer tube 130 . The outer tube 130 surrounds the middle and lower ends of the inner tube 120 , and the lower end of the outer tube 130 is longer than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com