LED (light emitting diode) light source for plant growth

A technology for LED light source and plant growth, applied in the field of plant supplementary light source, can solve the problems of high cost and uneven light mixing of LED light source, and achieve a well-developed root system, good uniformity and consistency of light color, and enhanced resistance and immunity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

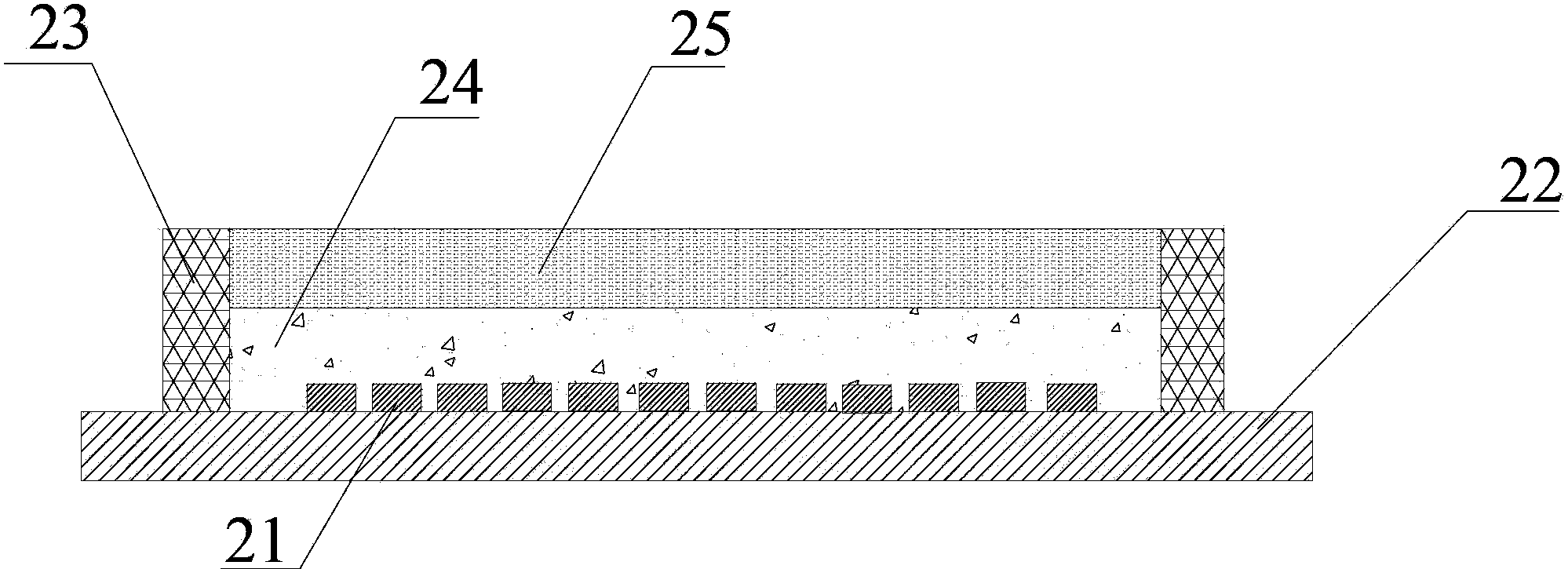

[0032] see figure 2 , on the ceramic heat dissipation substrate 22, use a dam dispenser to dispense glue to form a closed resin ring 23. The closed resin ring 23 can be square or circular. Other situations, such as rhombus or hexagon, are also allowed. In ceramic Several gallium nitride-based blue light chips 21 are mounted in the space formed by the heat dissipation substrate 22 and the closed dam 23. The gallium nitride-based blue light chips 21 are arranged in an array, and each row of gallium nitride-based blue light chips There are 12 chips 21 (but not limited to 12). Gallium nitride-based blue-ray chips 21 are sealed with silica gel, and then baked at 150°C for 1-3 hours to form a silica gel layer 24, and finally coat the surface of the silica gel layer 24 with Spread a layer of red phosphor powder 25, test its color coordinates when coating red phosphor powder 35, ensure that the color coordinates are near x==0.41, y==0.16, control the amount of red phosphor powder 35 ...

Embodiment 2

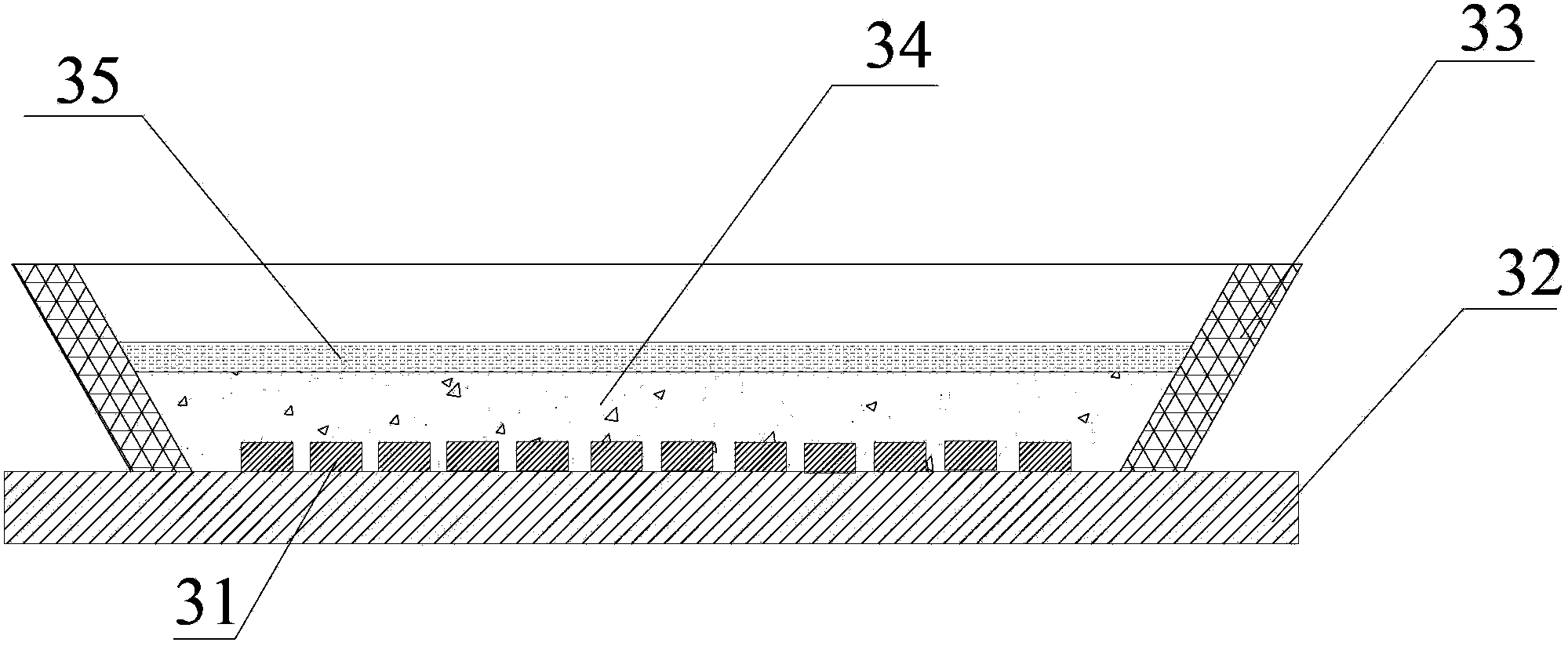

[0034] see image 3, above the metal-based heat dissipation substrate 32, a closed ring layer 33 formed of epoxy resin is fixed, and the closed resin ring layer 33 can be square or circular. Other situations, such as rhombus or hexagon, are also allowed. Several gallium nitride-based blue-ray chips 31 are mounted in the space formed by the heat-dissipating substrate 32 and the closed epoxy resin ring layer 33. The blue-ray chips 31 are arranged in an array, and each row of gallium nitride-based blue-ray chips 21 is 12 pieces (but not limited to 12 pieces), the gallium nitride-based blue-ray chip 31 is sealed with silica gel, and then baked at 150°C for 1-3 hours to form a silica gel layer 34, and finally coat a layer on top of the silica gel layer. Layer silicate-based red phosphor 35, test its color coordinates when coating red phosphor 35, ensure that the color coordinates are near x=0.41, y=0.16, control the amount of red phosphor 35 added through the color coordinates, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com