Stereoimaging test system and method for three-dimensional crystal surface growth kinetics model of crystals

A growth dynamics and three-dimensional imaging technology, which is applied in the direction of measuring devices, scientific instruments, and material analysis through optical means, can solve the problems of impracticality and low operation processing speed, and achieve fast image processing speed and high practicability , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

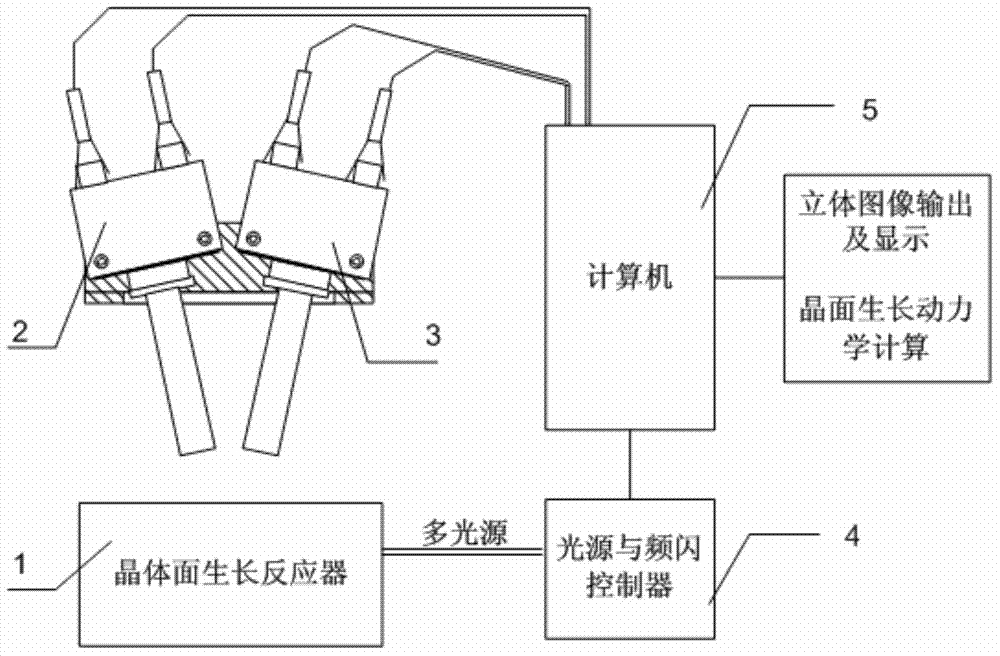

[0066] Such as figure 1 , 2 As shown, the three-dimensional imaging measurement system for crystal three-dimensional crystal plane growth kinetics includes a crystal plane growth reactor 1 equipped with a crystal to be measured, two camera heads 2 and 3 corresponding to the crystal plane growth reactor, and camera heads 2 and 3. 3 corresponding light source, light source and strobe controller for controlling the work of the light source 4, a computer 5 for image processing the images taken by the two camera heads and a display connected to the computer, the light source and the strobe controller are connected to the computer ,in

[0067] The two camera heads 2 and 3 are set at a fixed solid angle, and the angle range between the camera head and the central axis of the solid angle is 10 to 80 degrees, preferably 45 degrees, and the camera parameters are set to be the same and focus on the same sample area. The obtained 2D image of the crystal sample is transmitted to the comp...

Embodiment 2

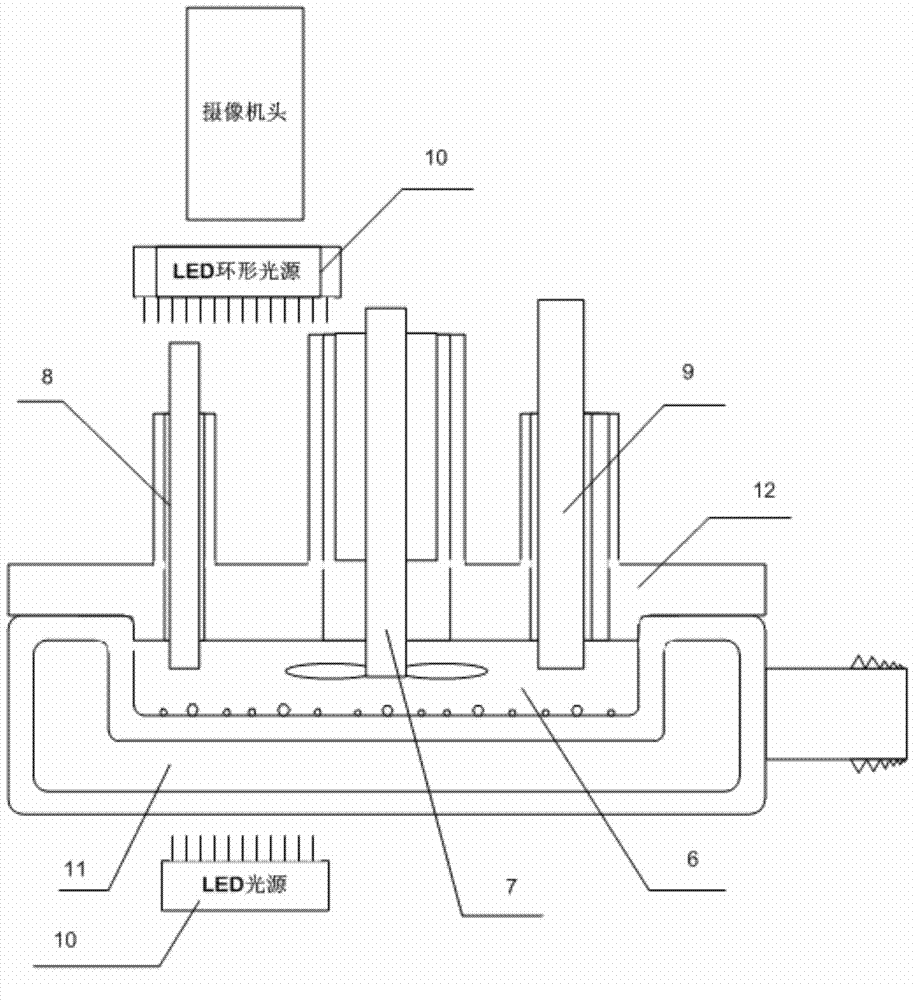

[0070] Such as figure 1 , 3 , the present embodiment has the same structure as embodiment 1 except the following features:

[0071] The crystal plane growth reactor includes a reactor cavity 13, a magnetic stirrer 15 arranged inside the reactor cavity 13, and probes for detecting solution parameters, such as a temperature probe 16 and a concentration probe 17. The light source 14 is arranged above and below the corresponding positions of the reactor cavity 13, and its irradiated position is consistent with the area where the camera focuses. A heating / cooling jacket 18 is arranged outside the reactor cavity 13, and the light source 14 is LED ring light source, the upper cover 19 of the reactor cavity 13 is quartz glass with ultra-low reflectivity.

Embodiment 3

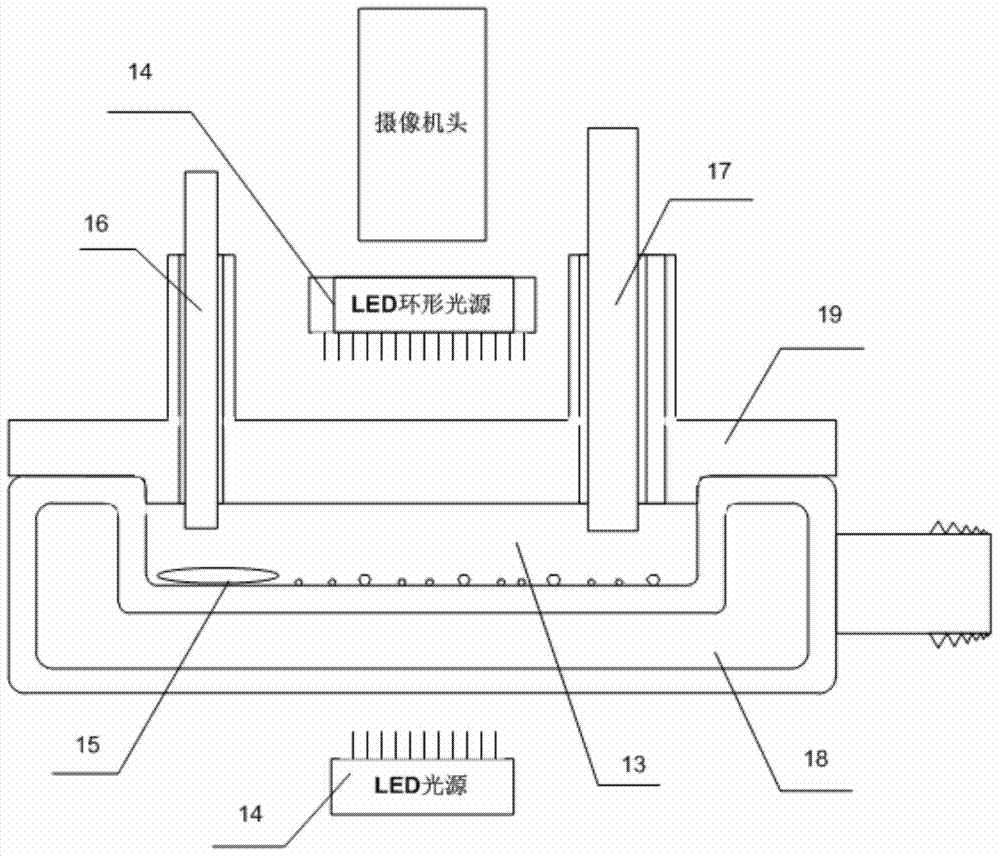

[0073] Such as figure 1 , 4 , the present embodiment has the same structure as embodiment 1 except the following features:

[0074] The crystal plane growth reactor includes a reactor cavity 20 and a crystal flow unit 21. A light source 22 is arranged above and below the crystal flow unit. The unit 21 is connected to the reactor chamber 20 through a conduit 23, and the reactor chamber 20 is provided with a blade stirrer 24 and probes for detecting solution parameters, such as a temperature probe 25, a concentration probe 26, and a pH probe 27.

[0075] For the above three embodiments, the following explanations need to be made:

[0076] 1. Whether the crystal to be tested needs to be fixed:

[0077] 1. When the stirring speed of the stirrer in the reactor cavity is slow or not stirring, and the flow speed of the solution in the crystal flow unit is slow or not flowing, the crystal to be tested does not need to be fixed, that is, in the actual operation process, Under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com