Three methods for detecting operation state of motor in rotation resisting switch

A technology of running state and anti-rotation is applied in the field of detecting the running state of the motor in the three kinds of anti-rotating switches, which can solve the problems of motor damage, adverse production influence, and high working environment temperature, and achieves the effects of intuitive display, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, this design patent is described in further detail.

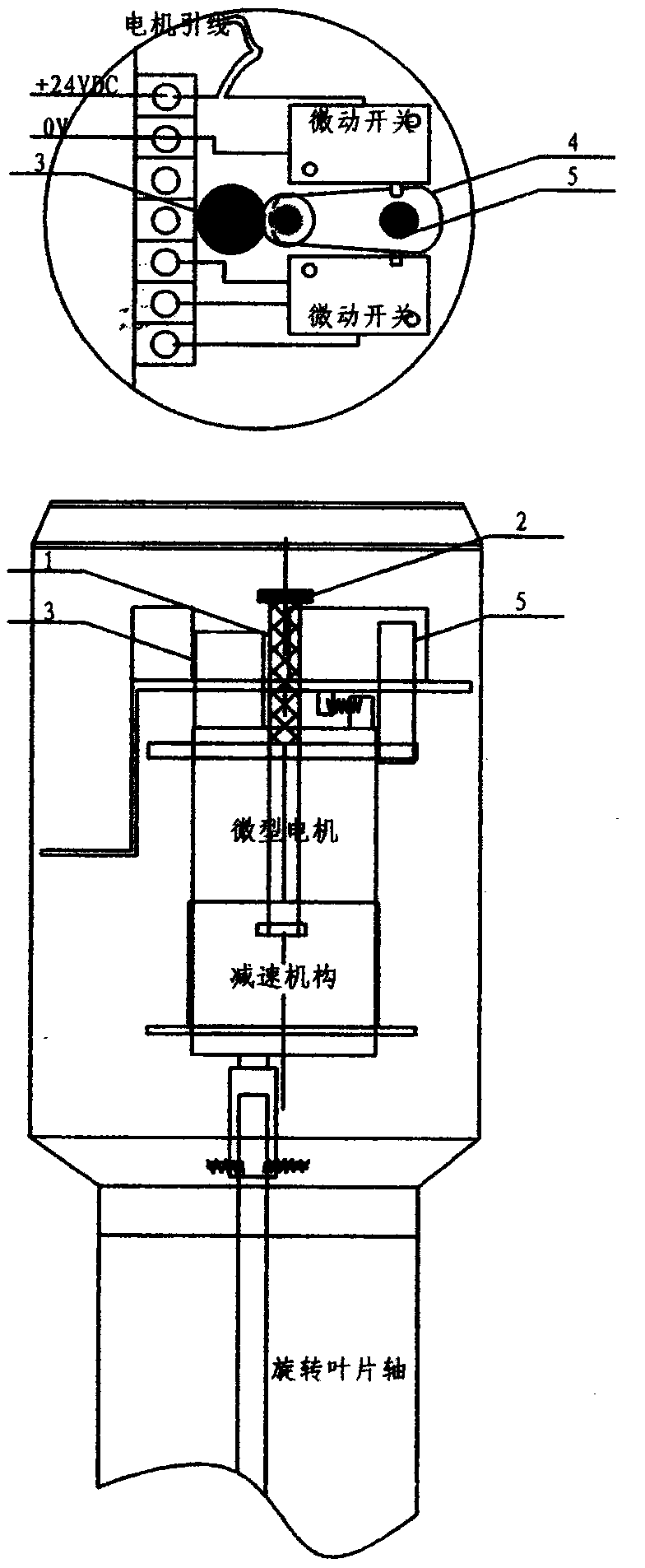

[0020] figure 1 . As shown, the driving mechanism of the rotary resistance type material level switch is composed of a micro motor and a reduction mechanism. The shaft of the micro motor is extended by about 30MM, slightly higher than the micro switch. See figure 1 The middle shaded part (1); and install a rotating indicator piece (2) at the end of the extended motor shaft. The extended shaft (1) of the micromotor needs to be explained when ordering the micromotor. Because the micro motor has a certain deflection margin in the controller, it is necessary to cut an irregular movable hole (4) on the panel of the controller to ensure the movement of the micro motor shaft (1) and the motor deflection shaft (5) . (3) is the fixing pin of micromotor and control panel.

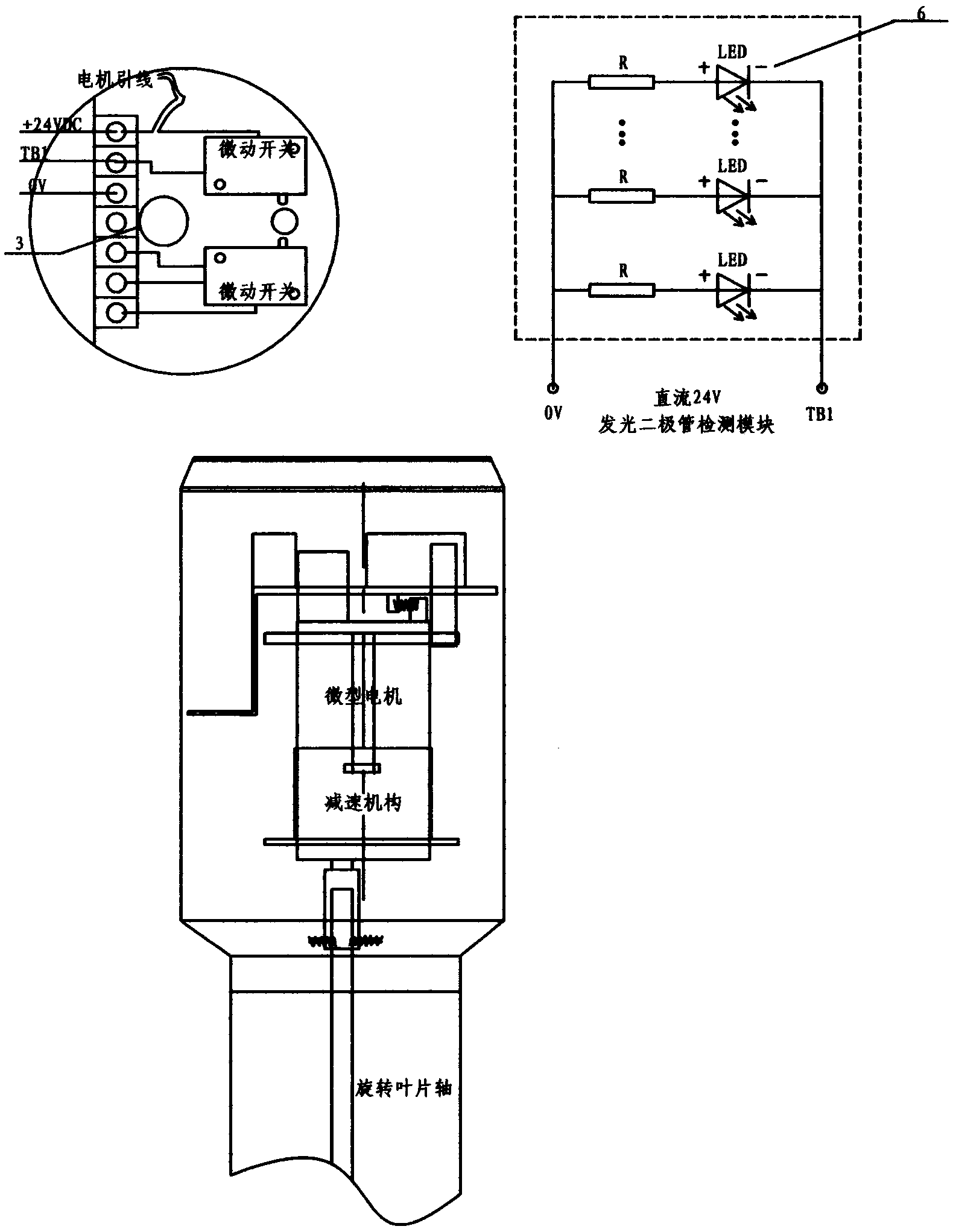

[0021] figure 2 As shown in ., the light emitting diode module (6) is only for the resistive rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com