Bismuth-doped yttrium vanadate semiconductor for photocatalytic degradation of ethylene

A yttrium vanadate and semiconductor technology, applied in the field of inorganic nano-photocatalytic materials, can solve the problems that have not yet been reported, and achieve the effect of promoting practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 1.628g of yttrium nitrate and 0.364g of bismuth nitrate, dissolve them in 50mL of acetic acid and water mixed solution, add 5.006g of acetylacetone and 7.010g of acetylacetone and stir for 1 hour after they are completely dissolved. Weigh 0.585g of ammonium metavanadate, dissolve it in 50mL of hot aqueous solution, add it to the above solution after it is completely dissolved, heat and stir until reflux, the solution changes from light yellow to reddish brown, keep for 3 hours, and then cool to room temperature. Take an appropriate amount of the solution and place it in a vacuum constant temperature drying oven, evaporate to dryness at 60°C, grind it into powder, put it into a muffle furnace and bake it at 550°C for 3 hours to obtain a bismuth-doped yttrium vanadate photocatalyst.

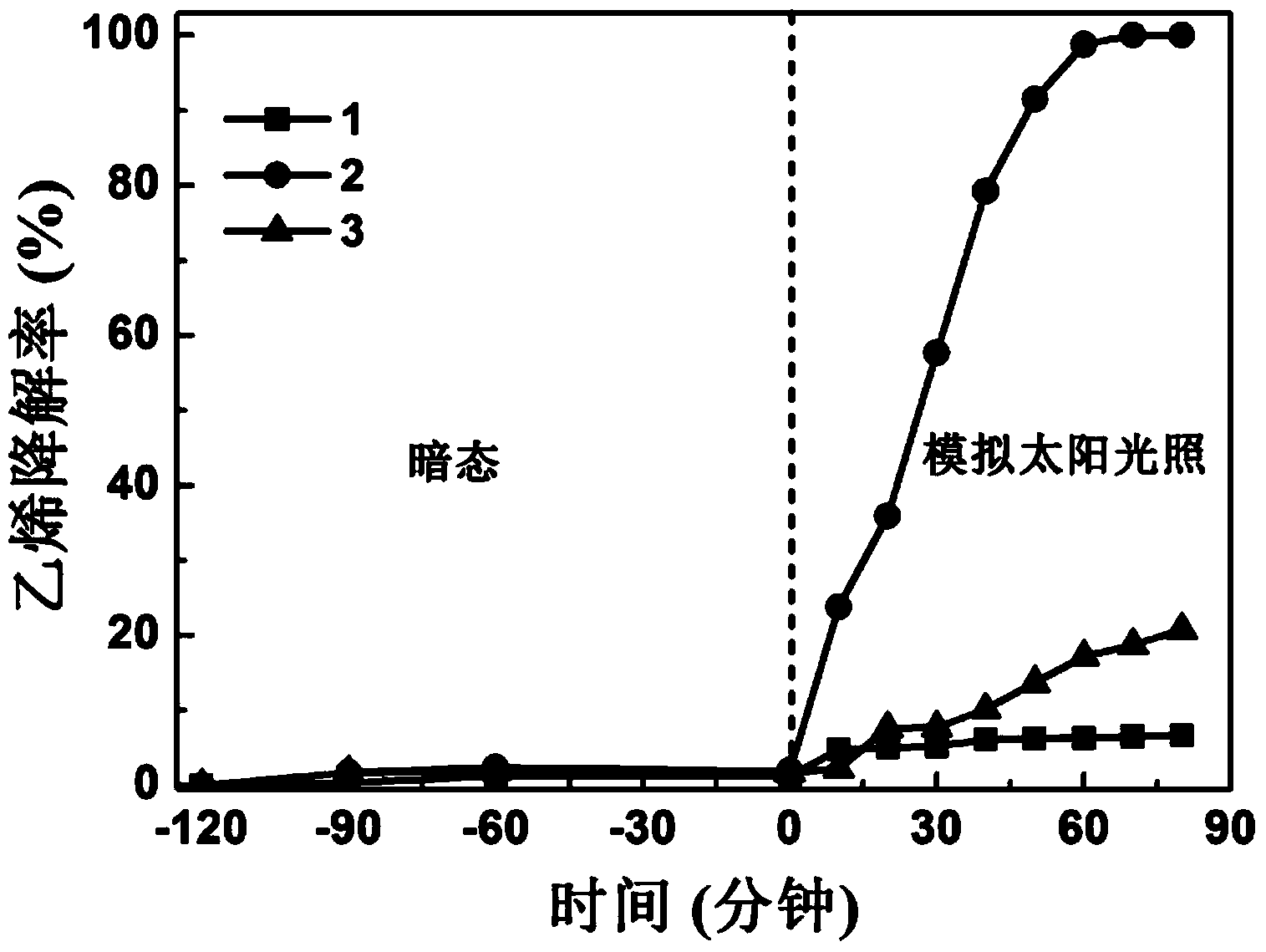

[0017] The photocatalytic performance test of the photocatalyst fixed bed degrading ethylene gas of the present invention is carried out under simulated sunlight. The experimental proc...

Embodiment 2

[0021] Weigh 1.628g of yttrium nitrate and 0.364g of bismuth nitrate, dissolve them in 50mL of acetic acid and water mixed solution, add 5.006g of acetylacetone and 7.010g of acetylacetone and stir for 1 hour after they are completely dissolved. Weigh 0.585g of ammonium metavanadate, dissolve it in 50mL of hot aqueous solution, add it to the above solution after it is completely dissolved, heat and stir until reflux, the solution changes from light yellow to reddish brown, keep for 3 hours, and then cool to room temperature. Take an appropriate amount of the solution and place it in a vacuum constant temperature drying oven, evaporate to dryness at 60°C, grind it into powder, put it into a muffle furnace and bake it at 550°C for 3 hours to obtain a bismuth-doped yttrium vanadate photocatalyst.

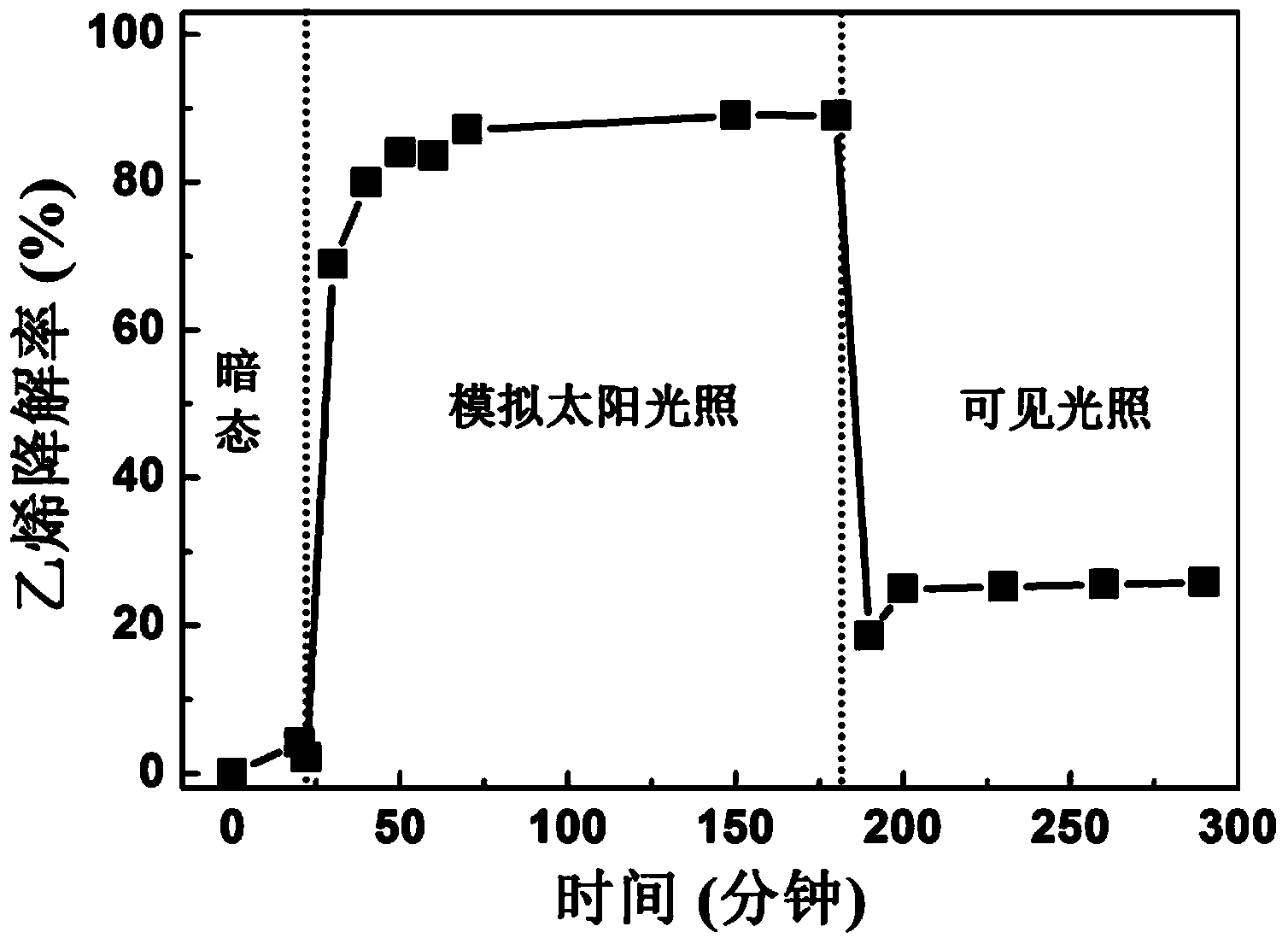

[0022] The photocatalytic performance test of the photocatalyst fluidized bed degrading ethylene gas of the present invention is carried out under simulated sunlight. The experimental ...

Embodiment 3

[0026] Weigh 1.4363g of yttrium nitrate and 0.6063g of bismuth nitrate, dissolve them in 50mL of acetic acid and water mixed solution, add 5.006g of acetylacetone and 7.010g of acetylacetone and stir for 1 hour after they are completely dissolved. Weigh 0.585g of ammonium metavanadate, dissolve it in 50mL of hot aqueous solution, add it to the above solution after it is completely dissolved, heat and stir until reflux, the solution changes from light yellow to reddish brown, keep for 3 hours, and then cool to room temperature. Take an appropriate amount of the solution and place it in a vacuum constant temperature drying oven, evaporate to dryness at 60°C, grind it into powder, put it into a muffle furnace and bake it at 550°C for 3 hours to obtain a bismuth-doped yttrium vanadate photocatalyst. Under simulated sunlight irradiation, the performance test results of gas-phase degradation of ethylene in fixed bed: the ethylene degradation rate reached 65% within 60 minutes; the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com