Patents

Literature

32 results about "Yttrium orthovanadate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium orthovanadate (YVO₄) is a transparent crystal. Undoped YVO₄ is also used to make efficient high-power polarizing prisms similar to Glan–Taylor prisms.

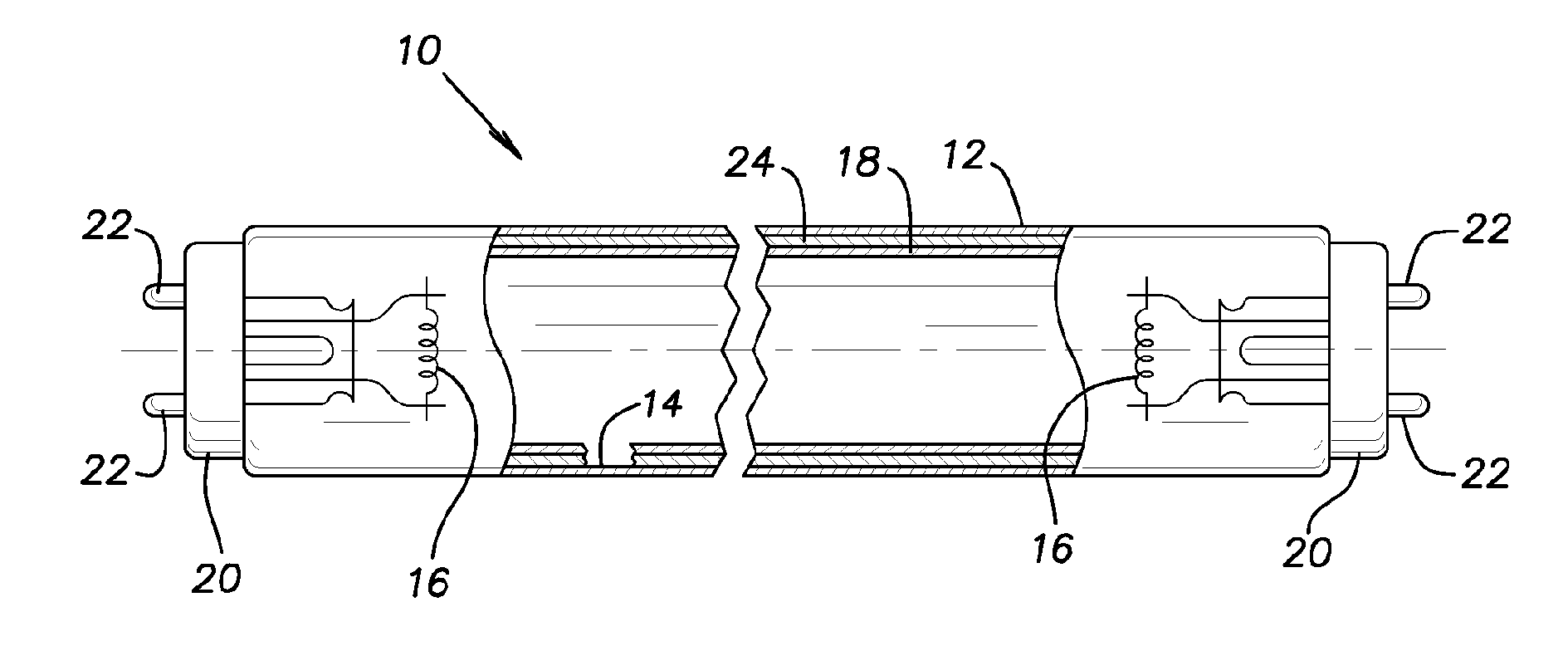

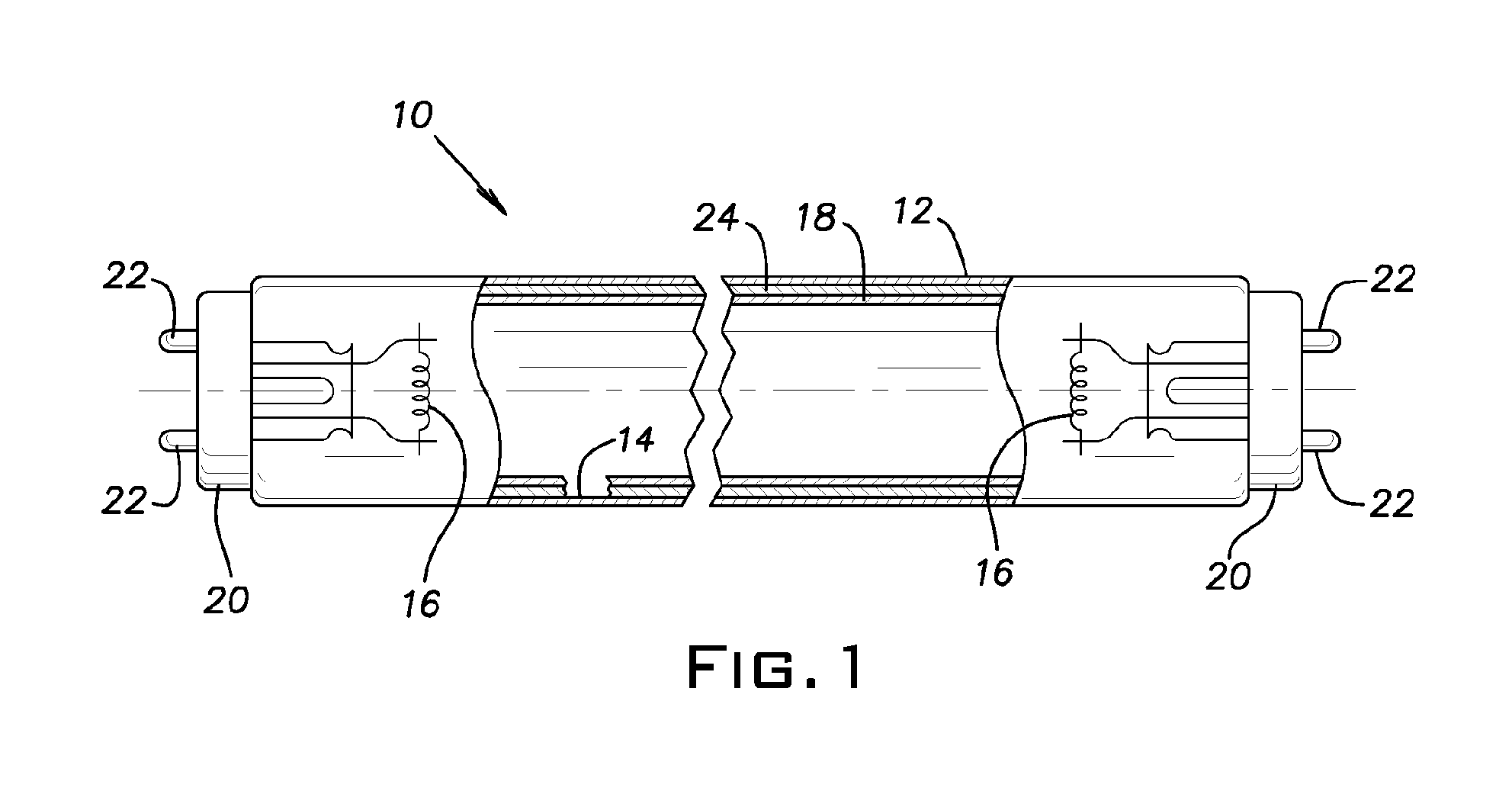

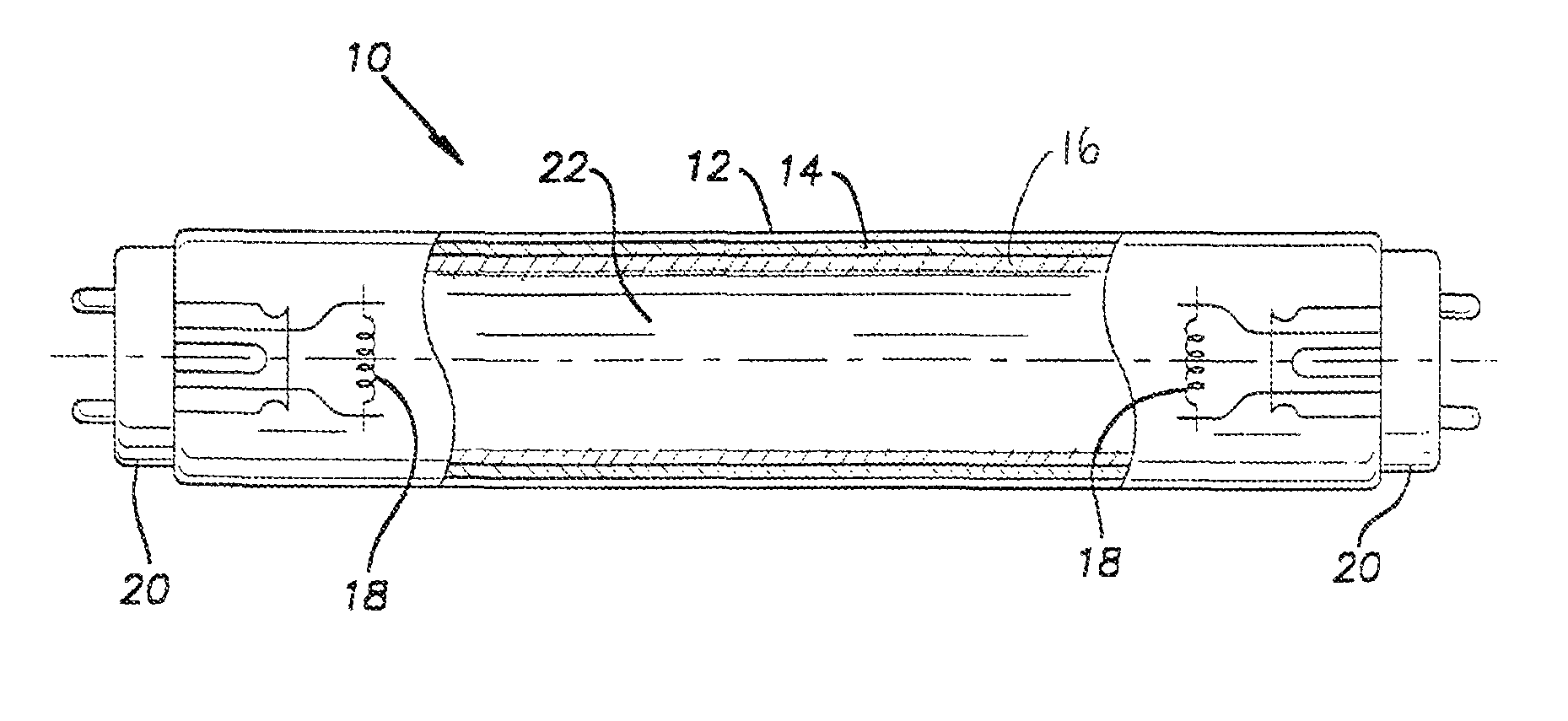

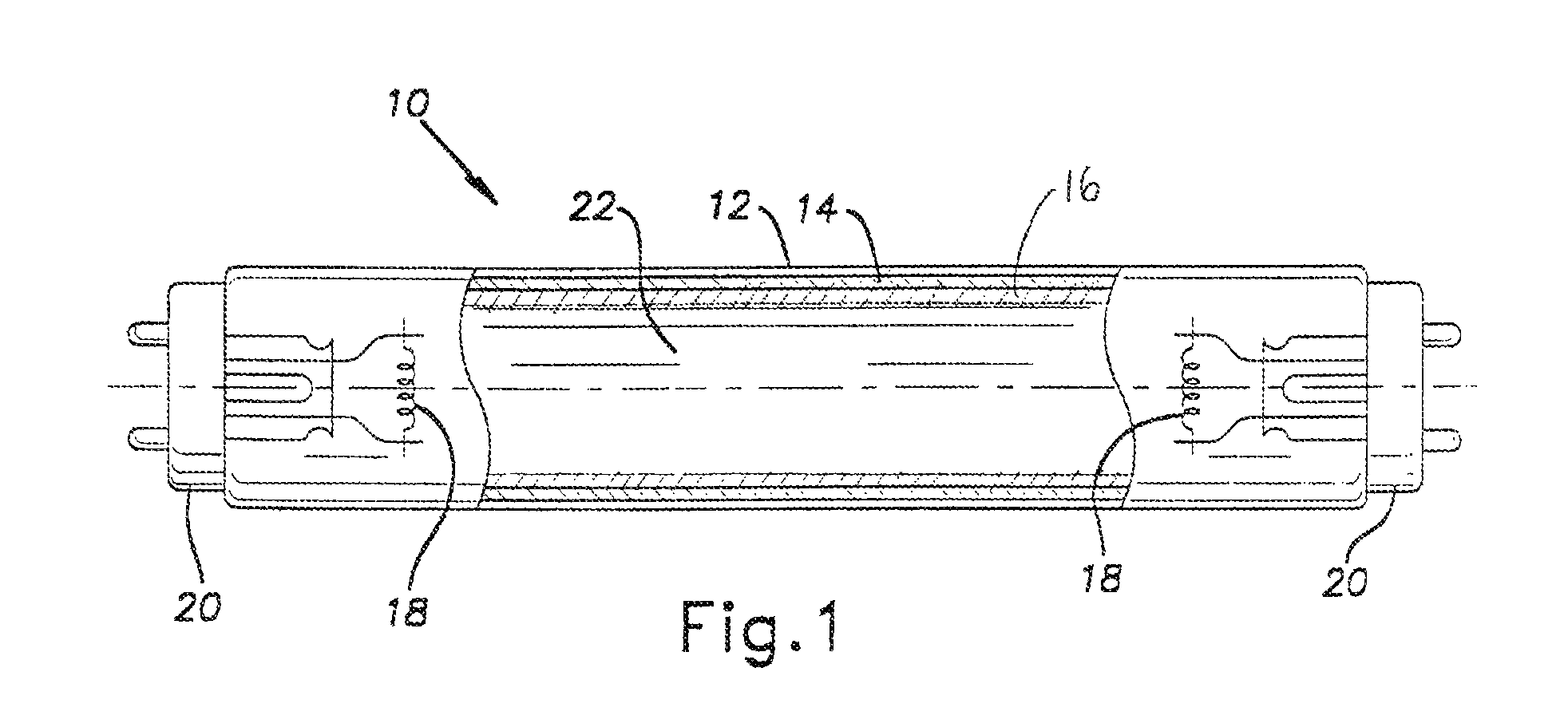

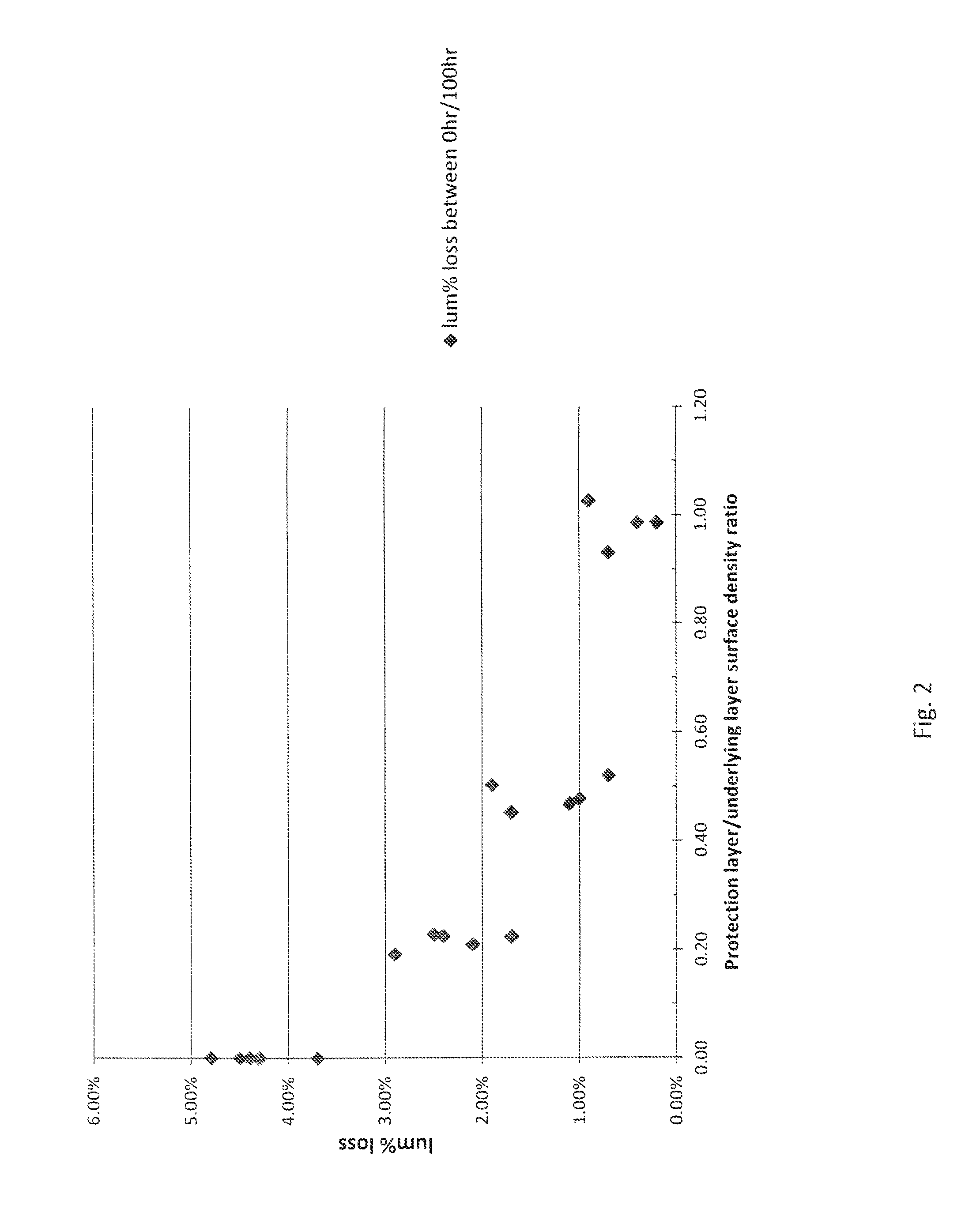

Fluorescent lamp with coated phosphor particles

This disclosure features fluorescent lamps that include a phosphor layer including at least one phosphor, which in the past has not been commercially usable in lamps or in some cases suffers from performance problems such as poor brightness. These problems of the phosphors were caused, for example, by mercury ion bombardment or exposure to 185 nm radiation from the discharge. These problems are expected to be avoided by coating particles of one or more of the phosphors, such as using atomic layer deposition in which the coating is not more than 500 nm in thickness. Examples of phosphors that can be coated are yttrium vanadate activated with europium or yttrium vanadate phosphate activated with europium. The coating can be selected from the group consisting of alumina, yttria, lanthanum oxide, magnesium aluminate spinel, magnesium oxide and combinations thereof.

Owner:GENERAL ELECTRIC CO

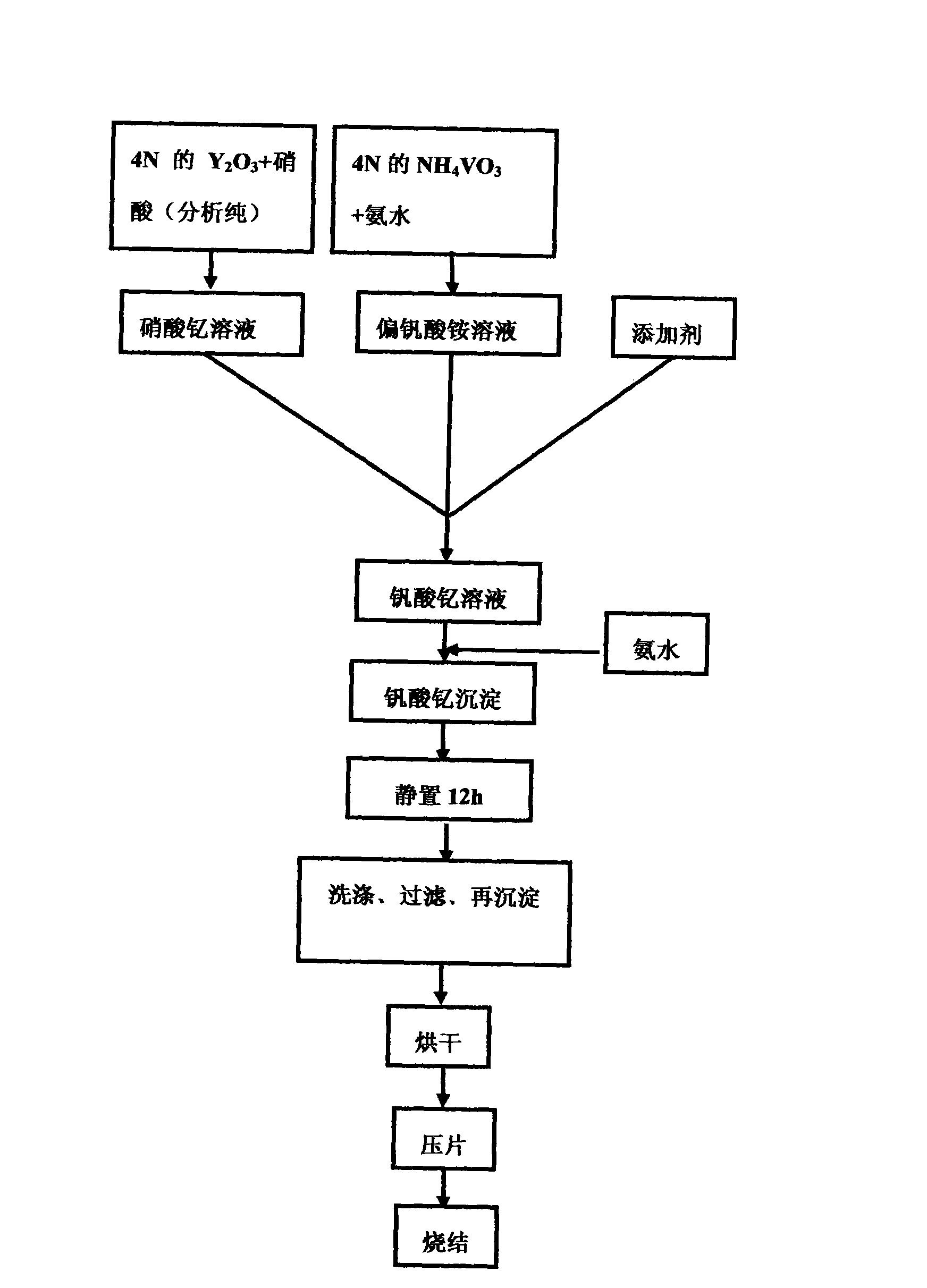

Raw material synthesis method for growing yttrium vanadate crystal through pulling method

ActiveCN101649489AQuality improvementReduce configuration requirementsPolycrystalline material growthSingle crystal growth detailsSal ammoniacSynthesis methods

The invention relates to a raw material synthesis method for growing yttrium vanadate crystal through pulling method and in particular to a preparation method of yttrium vanadate raw material doped with yttrium vanadate and rare earth ions (RE = Nd<3+>, Yb<3+> or Ce<3+>). The method is characterized in that the method comprises the following steps: dissolving ammonium metavanadate (NH4VO3) in aqueous solution of ammonia to obtain ammonium metavanadate solution; dissolving yttrium oxide in nitric acid to obtain yttrium nitrate solution; mixing the two solutions fully, adding proper additive solution, dropwise adding the mixed solution in aqueous solution of ammonia to maintain a certain pH value for the solution and obtain yttrium vanadate precipitate; standing precipitate for some time, washing, filtrating, performing reprecipitation; drying the obtained yttrium vanadate, tabletting and finally sintering the pressed yttrium vanadate at high temperature for some time. The yttrium vanadate raw material obtained by the invention can be used for growing monocrystal through pulling method, the obtained crystal has good quality, no obvious scattering, stripe and dark spot, and the finished product ratio of yttrium vanadate crystal is high.

Owner:保山鑫隆电子科技有限公司

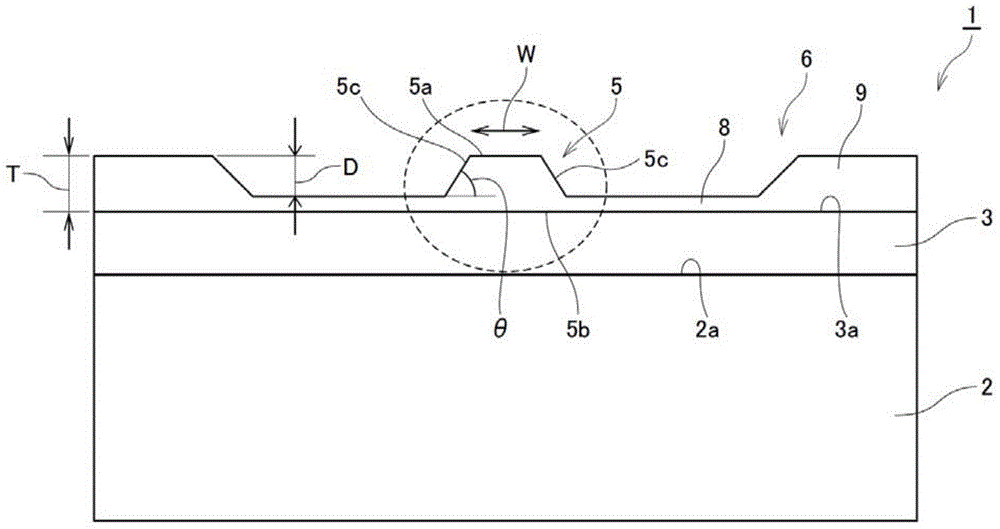

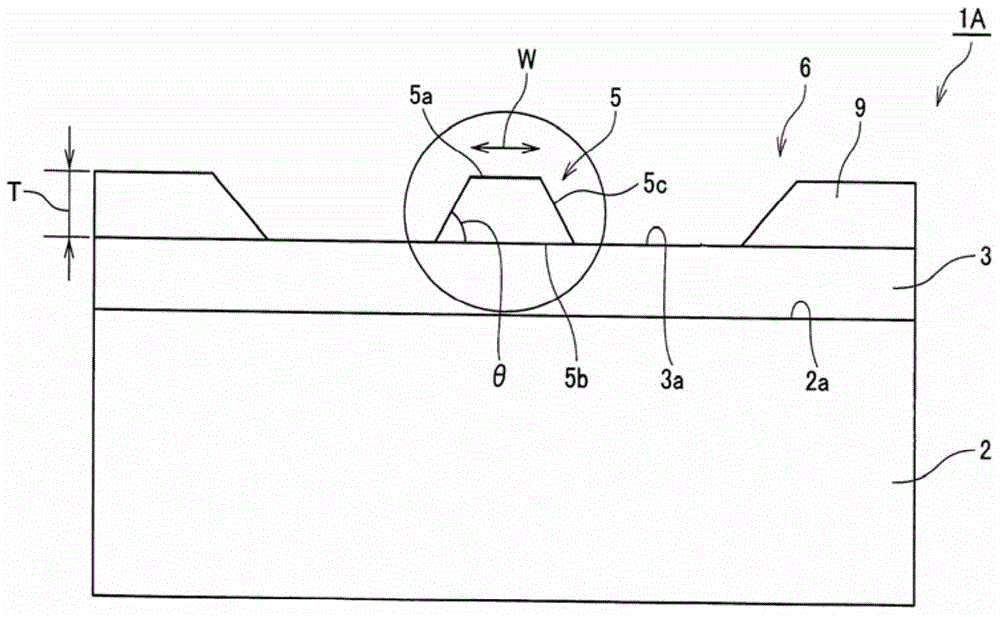

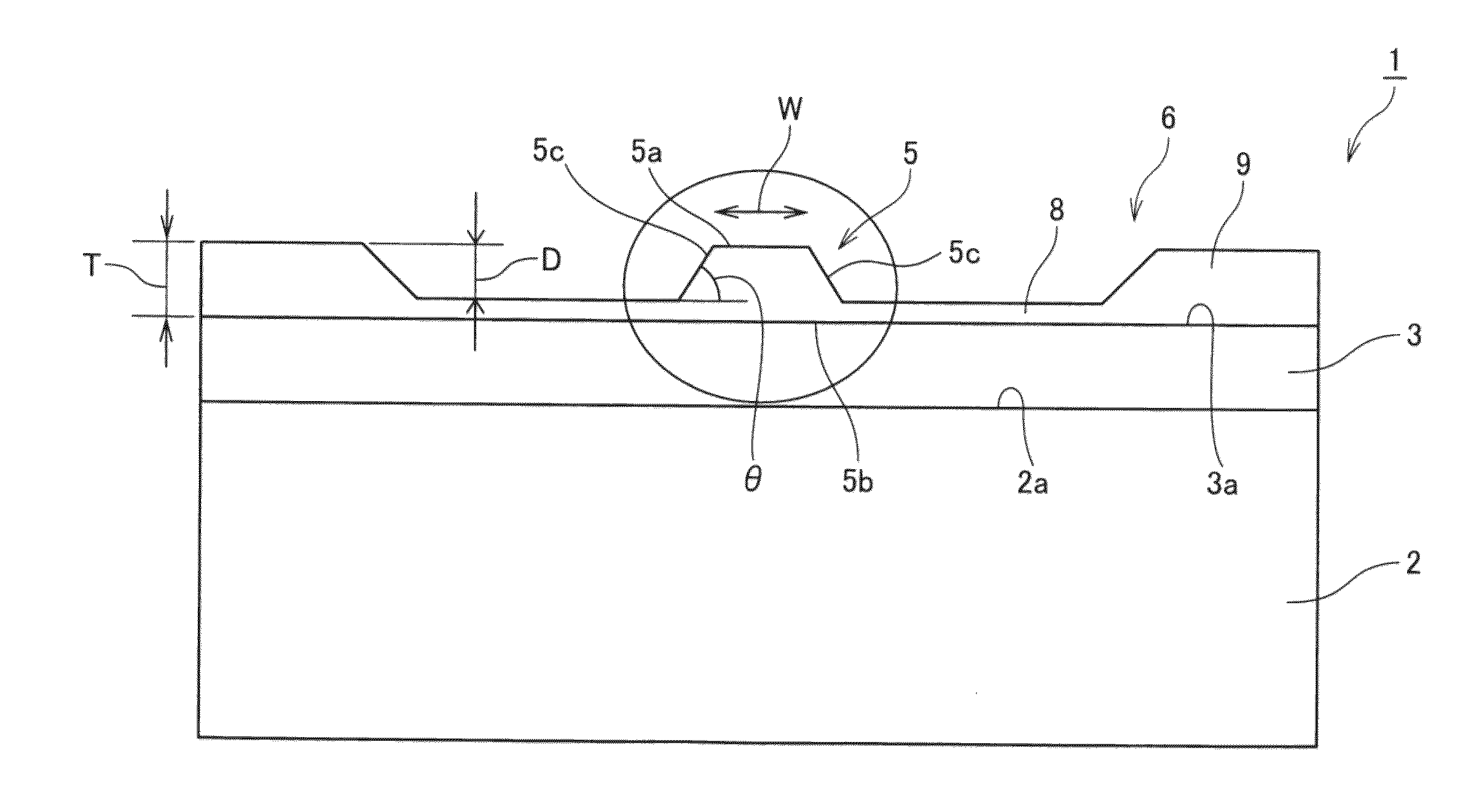

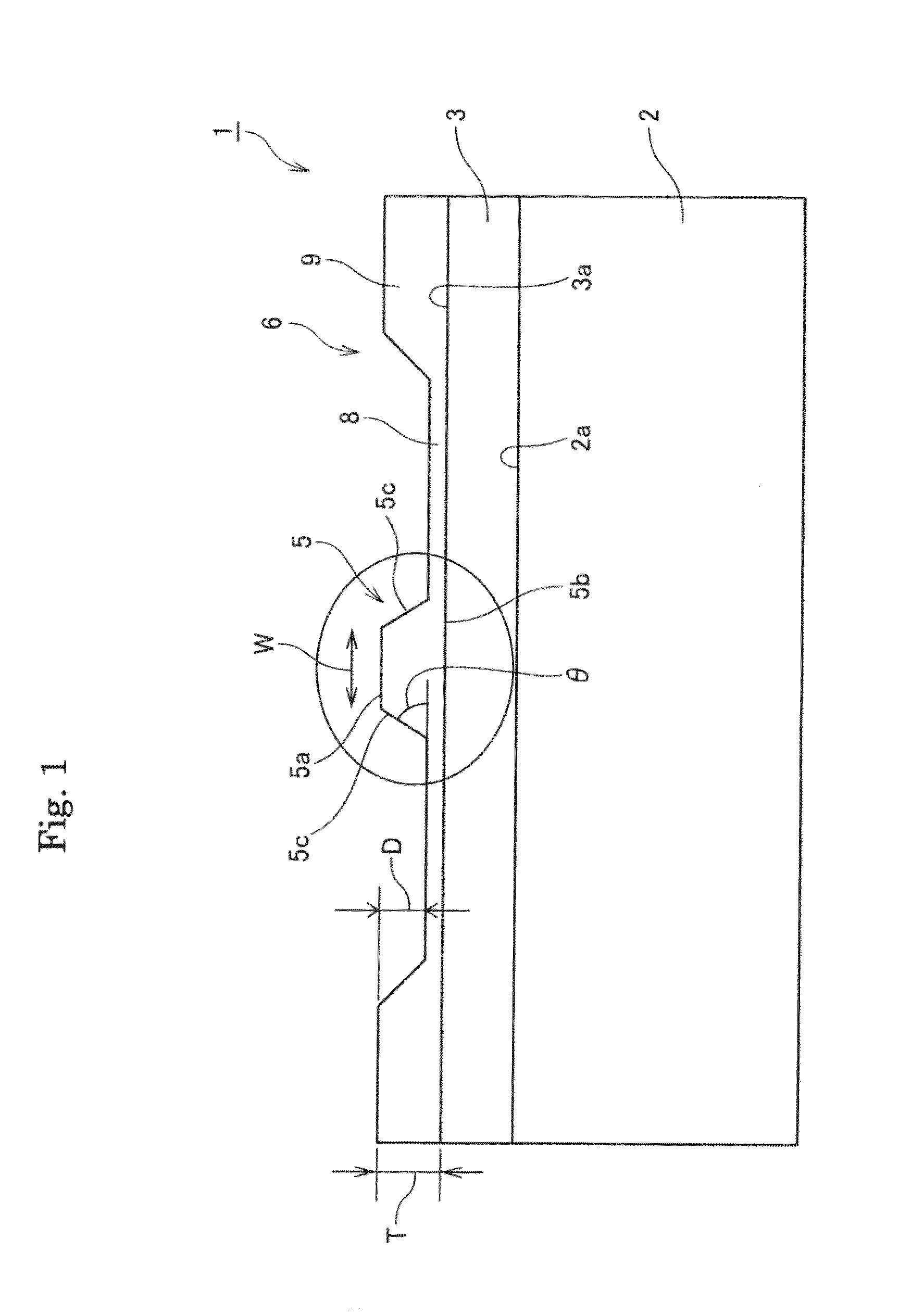

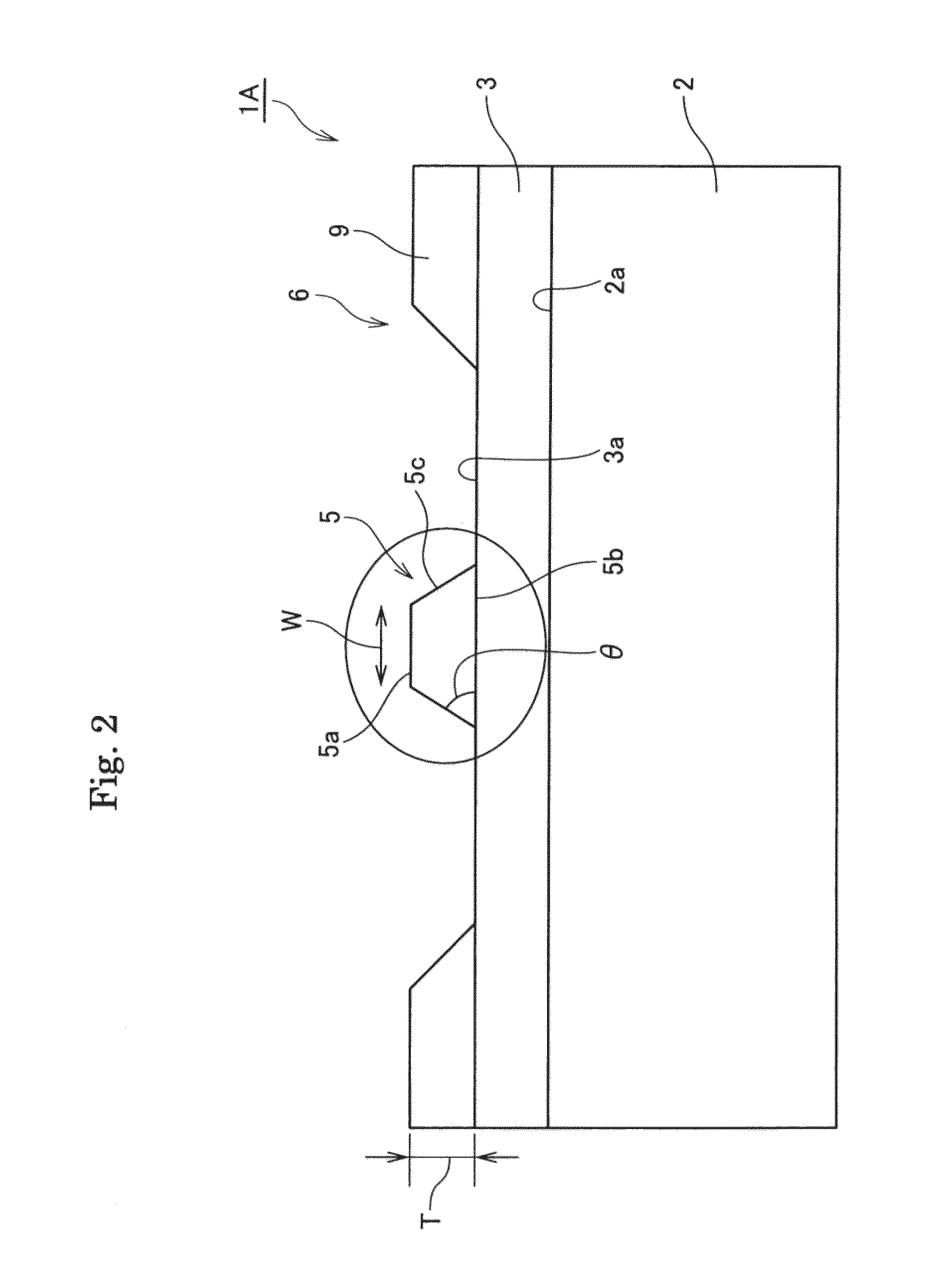

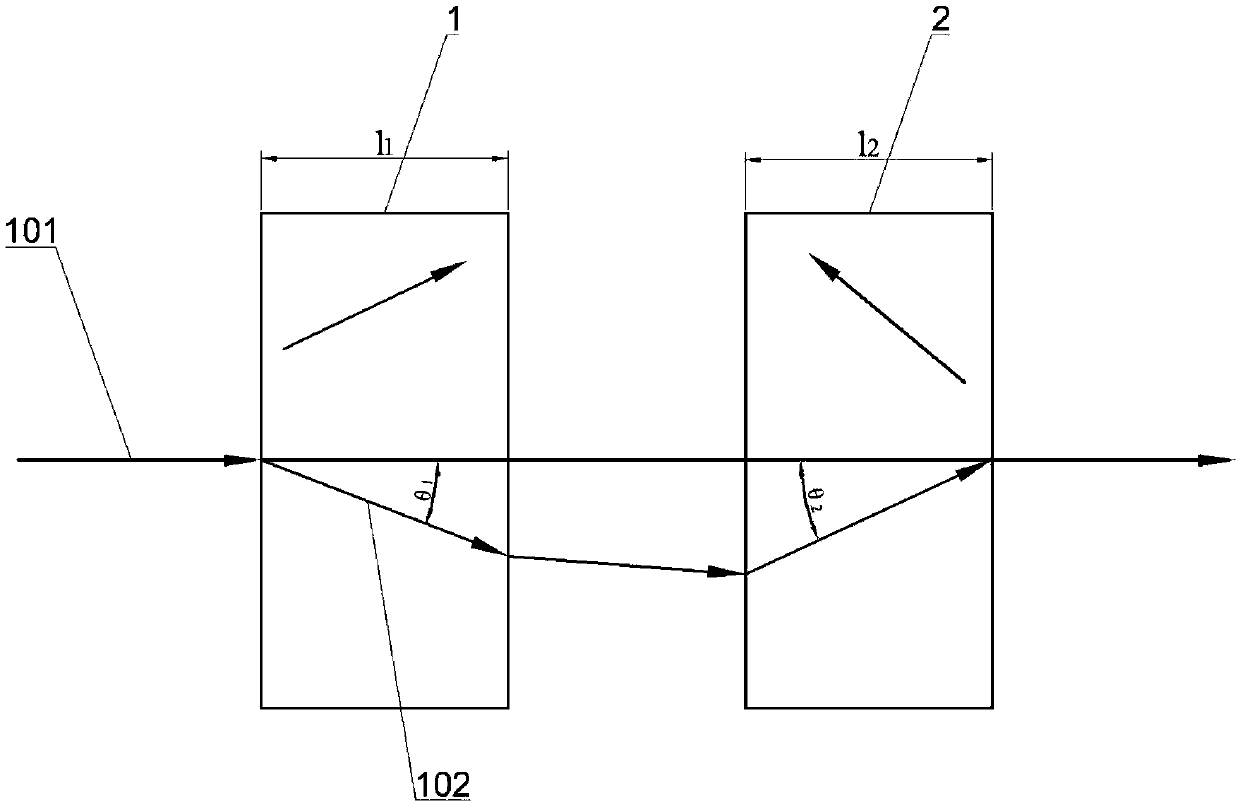

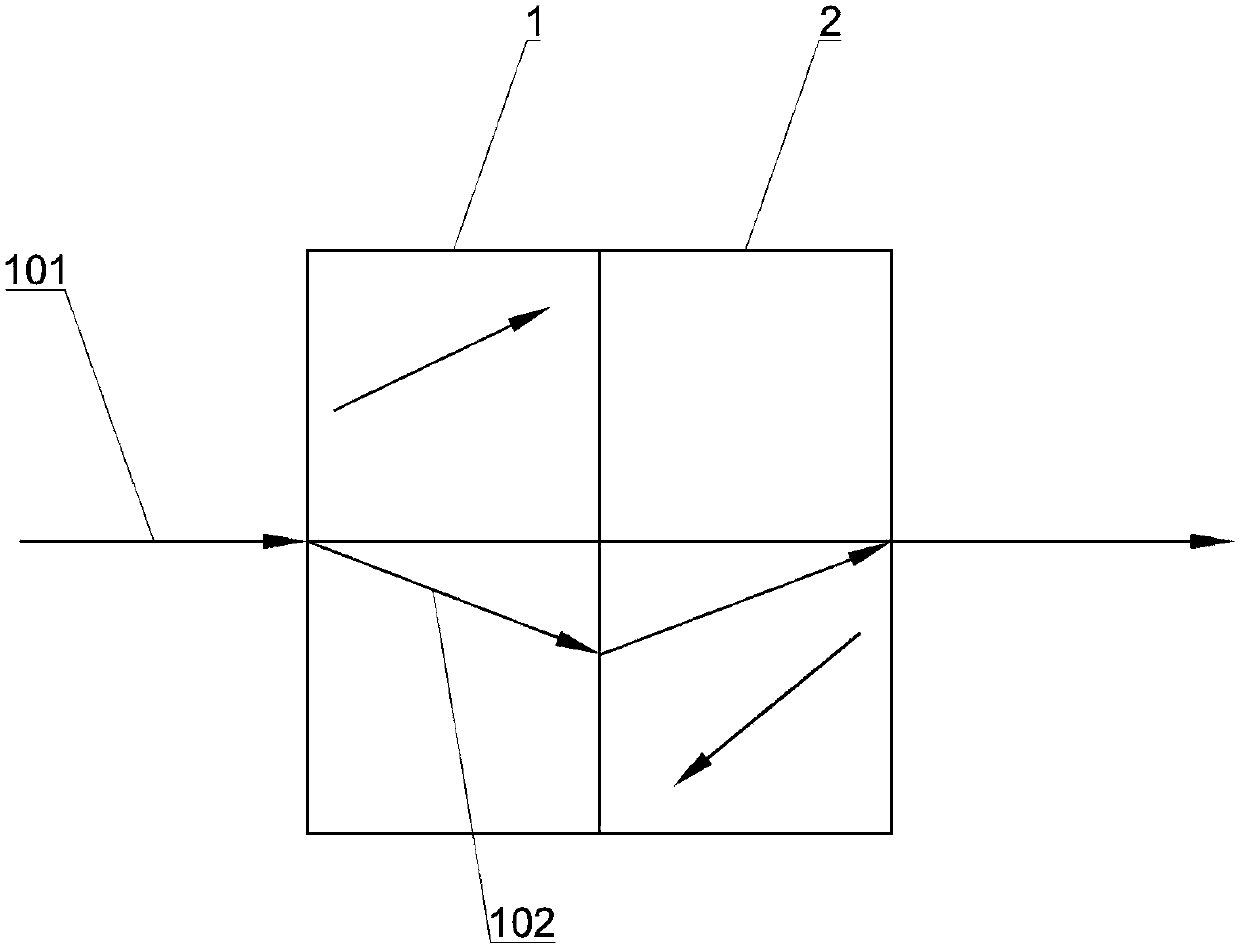

Optical waveguide devices

ActiveCN104678494ADesign freedomSuppression of propagation lossOptical light guidesNon-linear opticsTungstatePotassium

An optical waveguide device 1 includes a thin layer 3 and a ridge portion 5 loaded on the thin layer 3. The thin layer 3 is made of an optical material selected from the group consisting of lithium niobate, lithium tantalate, lithium niobate-lithium tantalate, yttrium aluminum garnet, yttrium vanadate, gadolinium vanadate, potassium gadolinium tungstate; and potassium yttrium tungstate. The ridge portion 5 is made of tantalum pentoxide and has a trapezoid shape viewed in a cross section perpendicular to a direction of propagation of light. The ridge portion is not peeled off from the thin layer in a tape peeling test.

Owner:NGK INSULATORS LTD

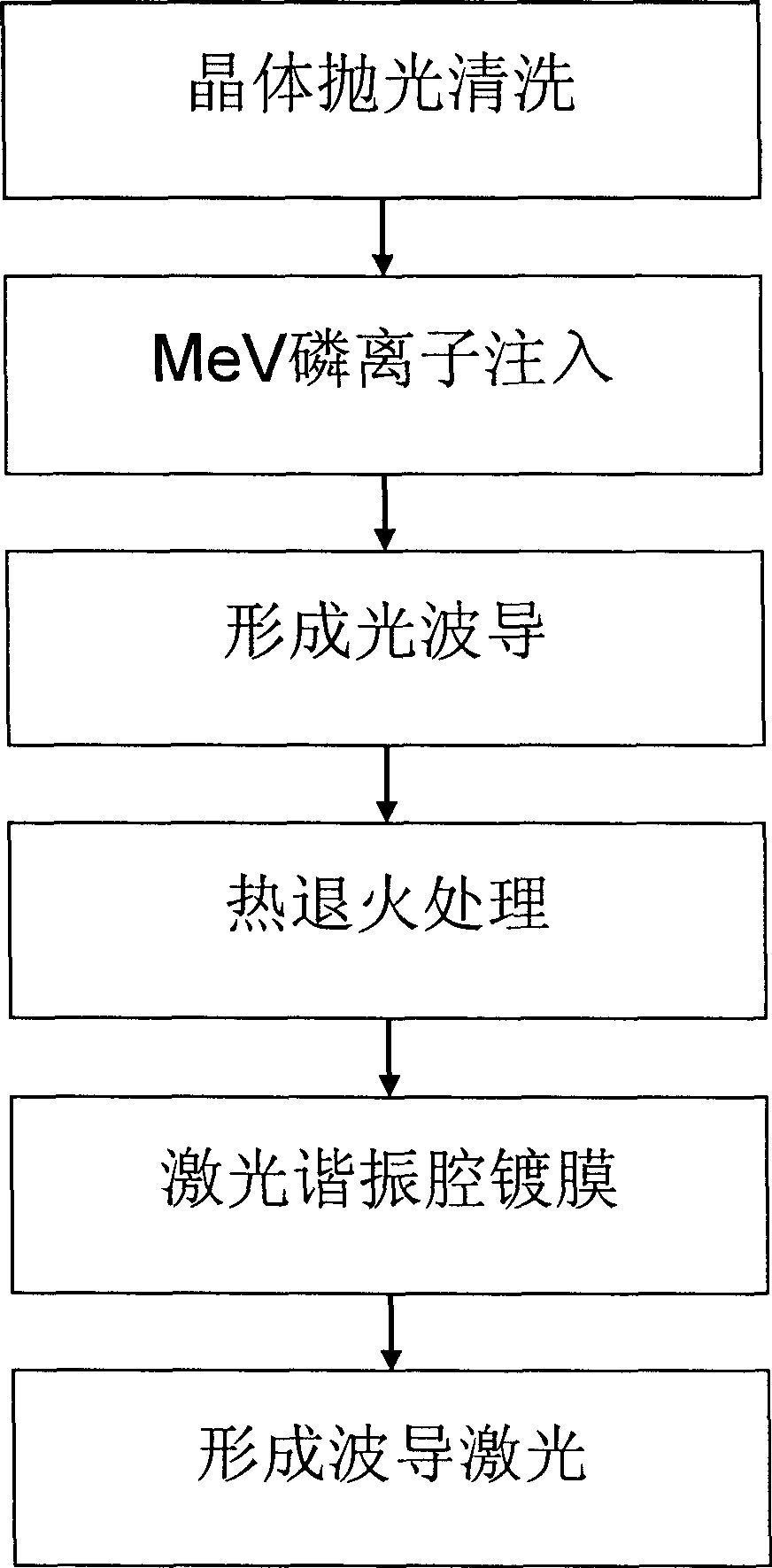

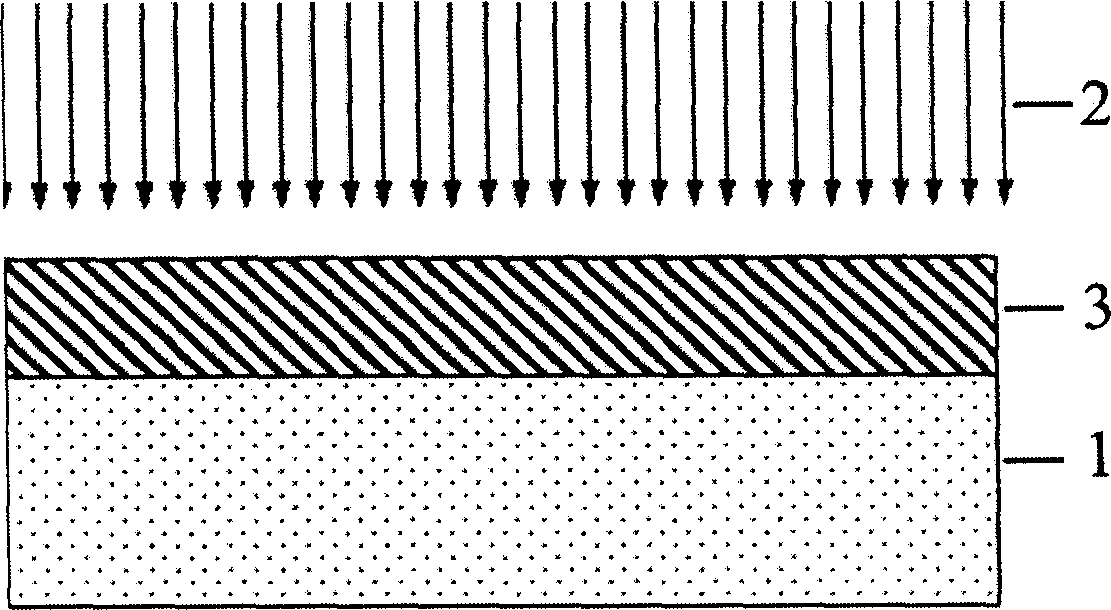

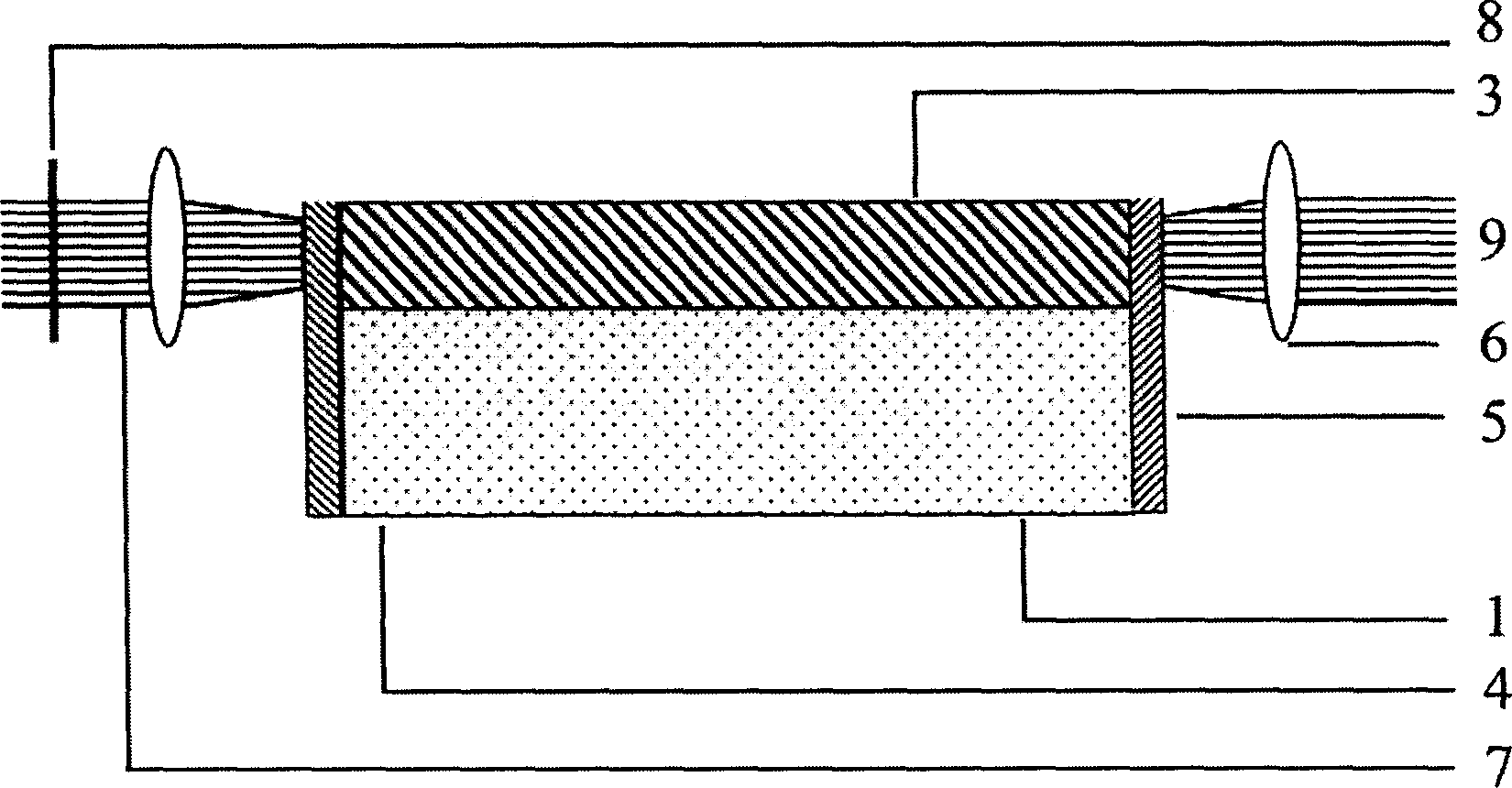

Method for preparing neodymium doped yttrium vanadate crystal waveguide laser by ion implantation

This invention relates to a method for preparation of crystal waveguide laser with ion implantation, mainly forming a plane and strip waveguide in Nd:YVO4 crystal and strip waveguide laser output, applying P ion implantation with energy power of 2.0-6.0 Mev, dose of 1X10 to the power 12 - 5X10 to the power 15 ions / cm2 to form plane light waveguide on Nd3+: YVO4 crystal surface or form a strip mask first, then to proceed with P ion implantation to form the Nd3+: YVO4 strip light waveguide to pump the plane or strip waveguide with a certain wavelength and power laser, to output infrared laser with the wavelength of about 1064nm after laser cavity coating to its end face.

Owner:SHANDONG UNIV

White fluorescent powder of Yt-doped vanadic acid, preparation method and application thereof

InactiveCN101381603AChange in luminescenceHigh luminous intensityCathode ray tubes/electron beam tubesVanadium compoundsHead-up displayIndium

The invention discloses yttrium vanadate doped indium white fluorescent powder, which has a general formula of composition: Y1-xInxVO4, wherein x is the value of the molar ratio of indium as an activating agent and is more than 0 and less than or equal to 0.07. The invention adopts the prior solid-phase synthesis method, creatively adds In<3+> into YVO4 fluorescent powder to obtain the yttrium vanadate doped the indium white fluorescent powder which can emit white light; and the white fluorescent powder has strong luminous intensity and can be applied to equipment and a device which utilize photoluminescence and luminous property excitated by cathode ray of the fluorescent powder, in particular to a projection television display, an FED and a Head-up Display and other occasions which have high requirement on the luminous brightness and the luminous efficiency of the fluorescent powder and has important industrial application value. In addition, the method for preparing the white fluorescent powder is simple and easy to operate; raw materials are cheap and easy to obtain; and the white fluorescent powder is suitable for industrialized production, has no three industrial wastes basically in the reaction process and belongs to an industry with environmental protection, low energy consumption and high benefit.

Owner:SHANGHAI NORMAL UNIVERSITY

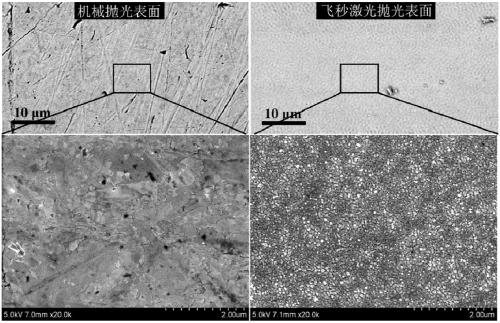

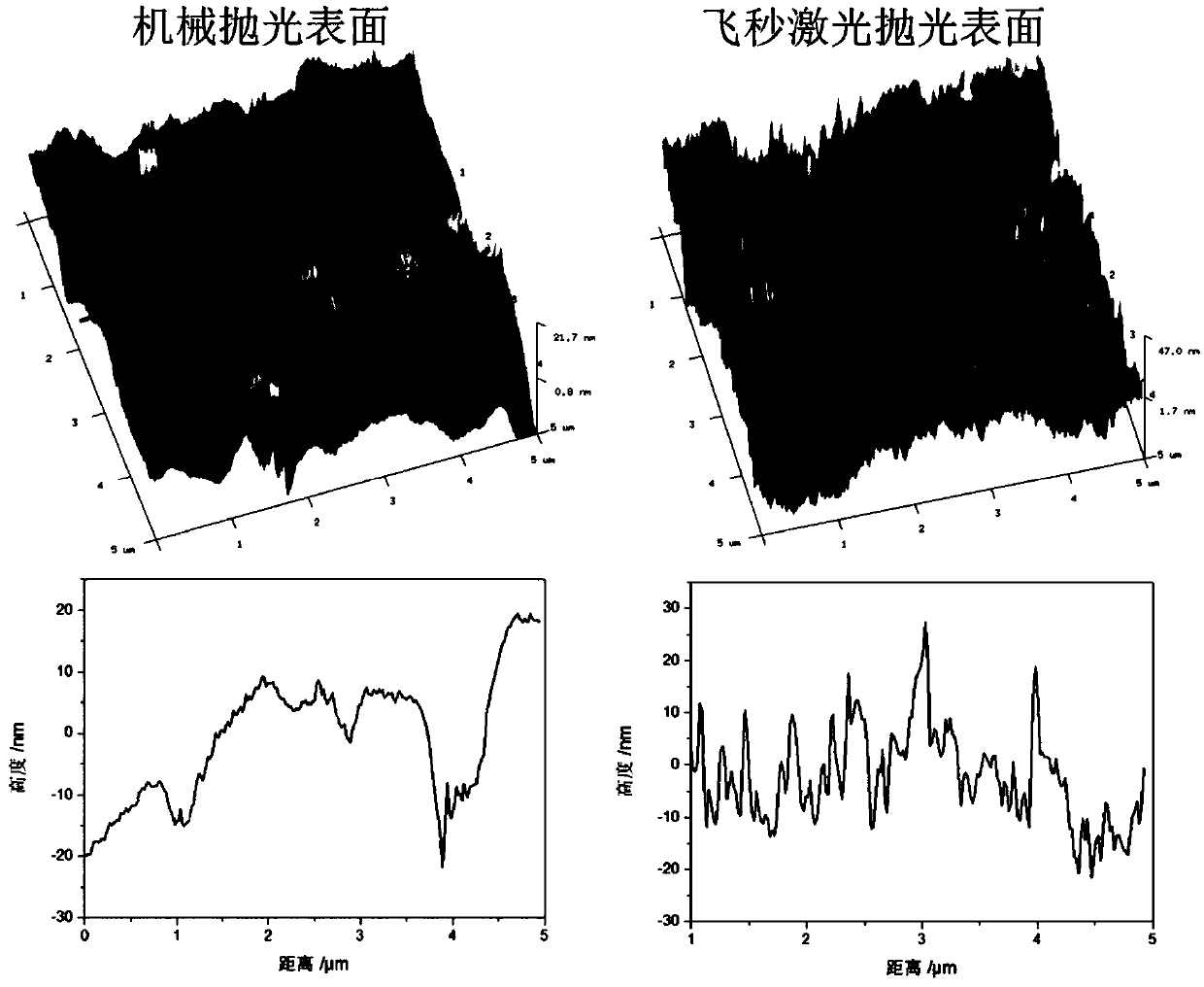

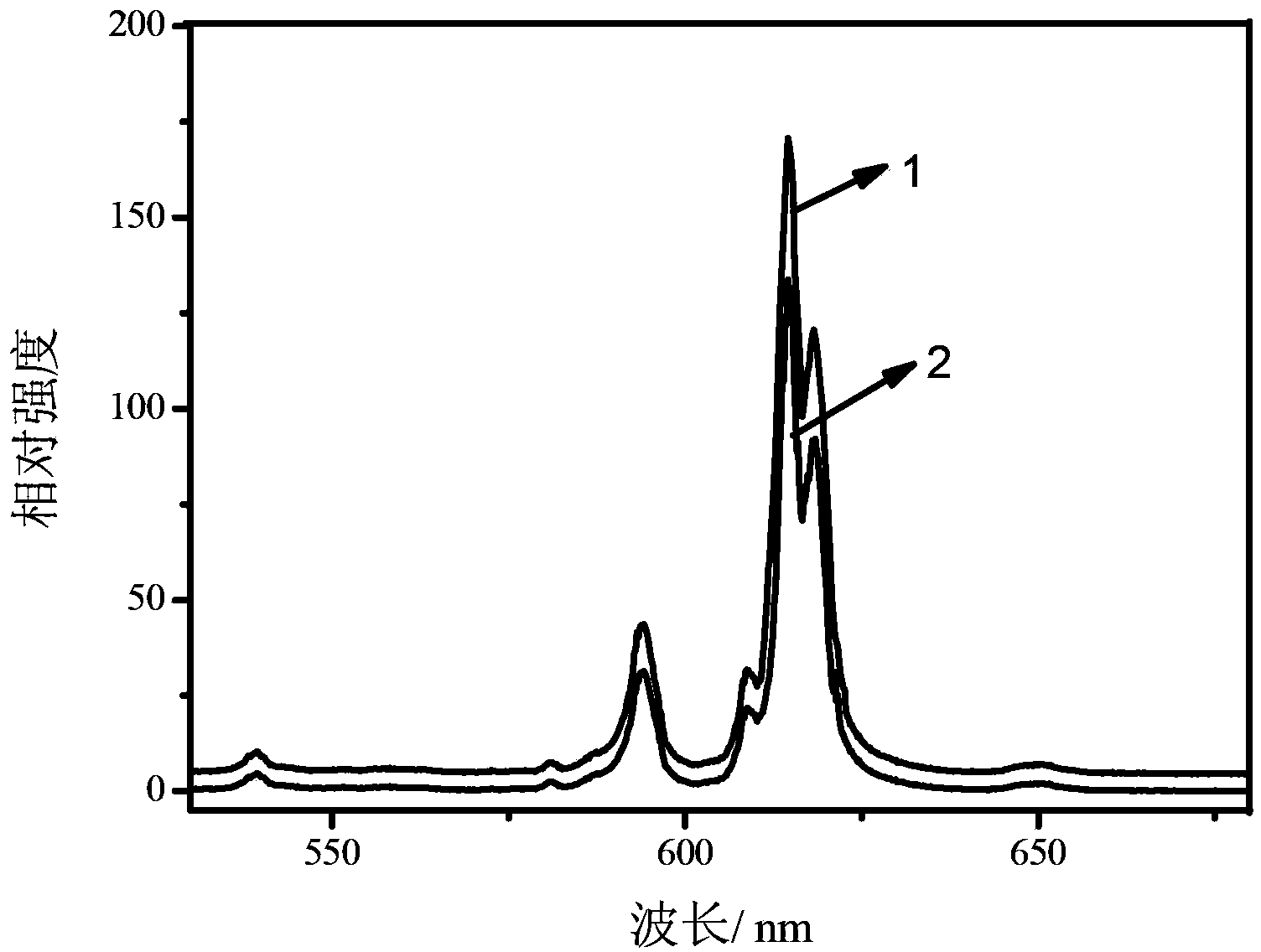

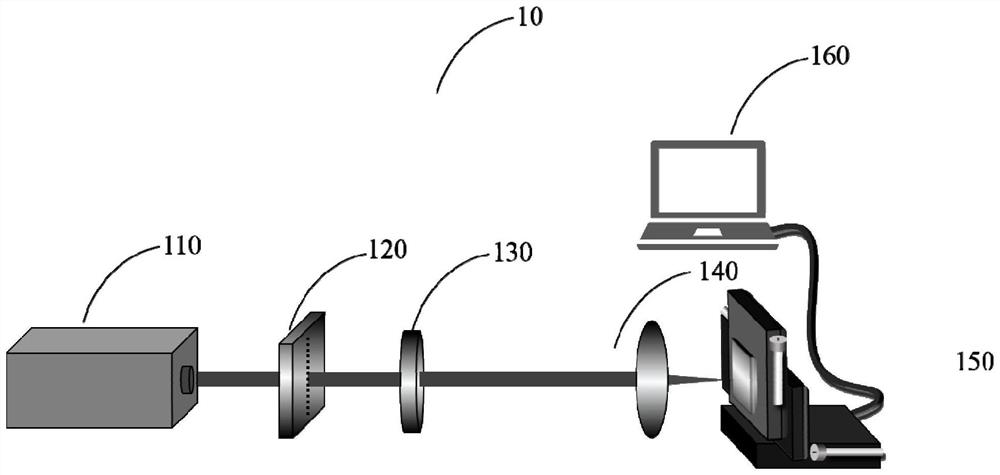

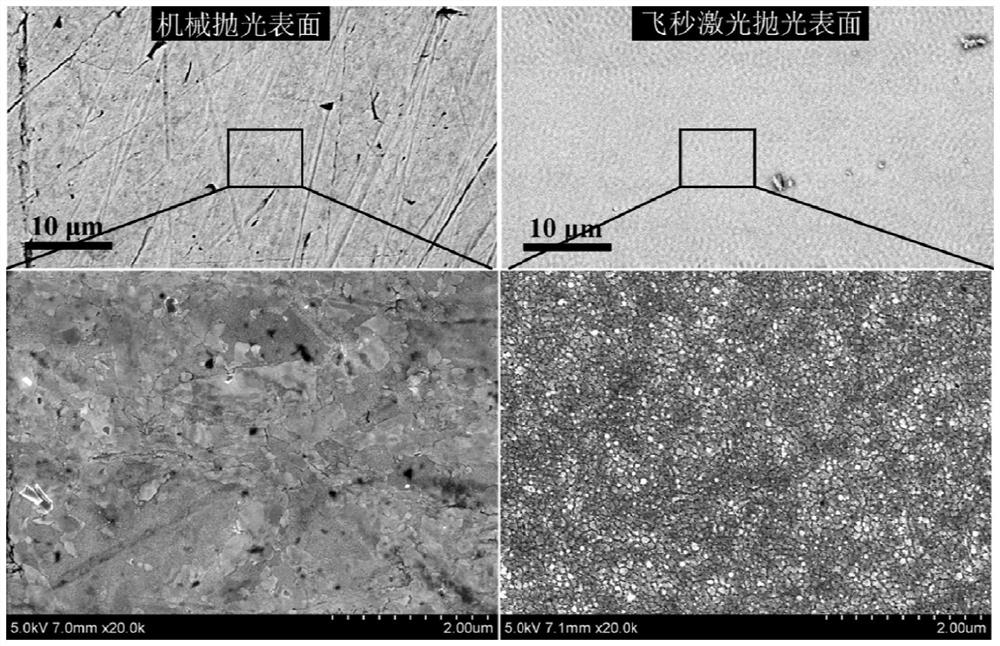

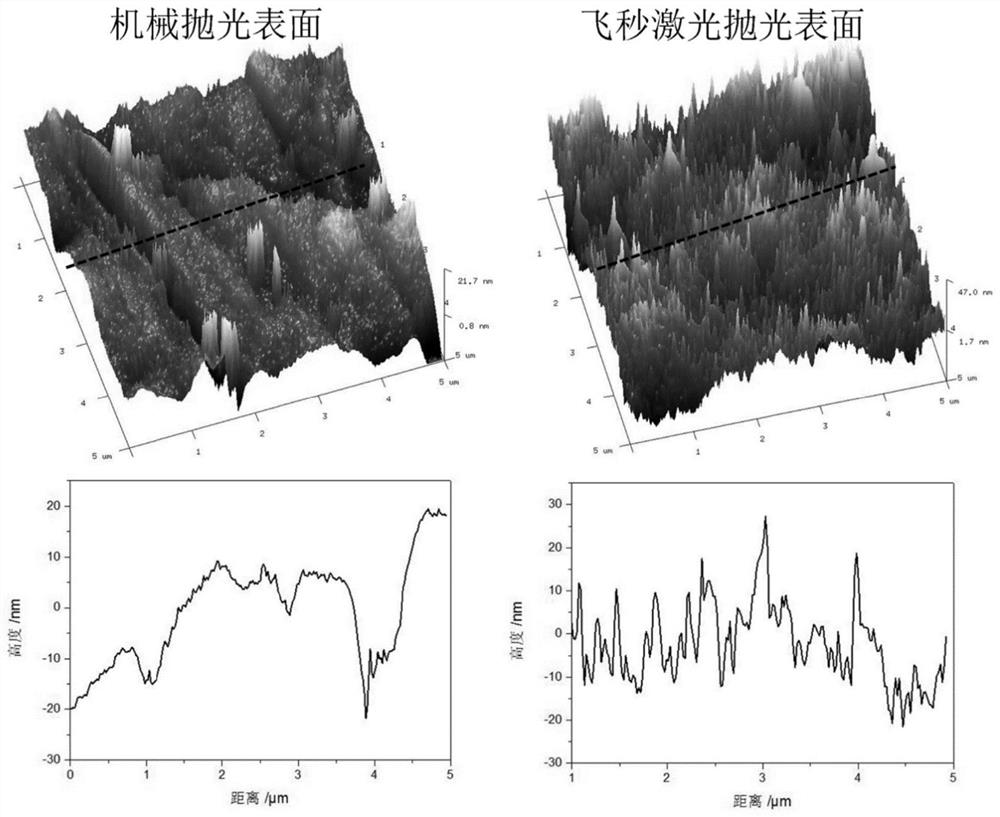

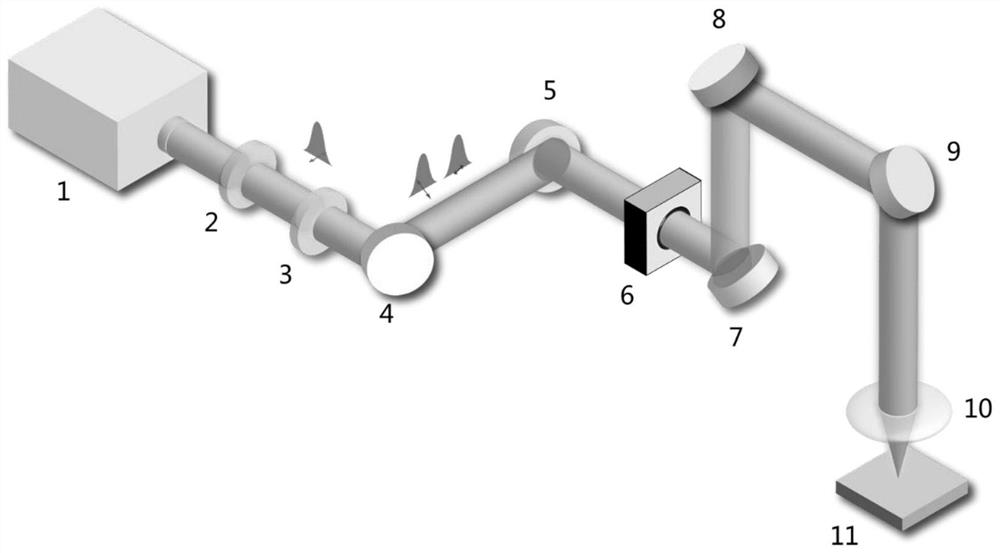

Optical device for metal surface polishing

ActiveCN111375897AAvoid destructionAvoid contaminationLaser beam welding apparatusBirefringent crystalFemto second laser

The invention provides an optical device for metal surface polishing. A laser beam emitted from a femtosecond laser light source passes through a yttrium vanadate birefringent crystal, an attenuationpipe and a focusing objective lens to be focused on a metal surface on a 3D mobile platform and conduct laser polishing treatment on the metal surface to obtain the smooth polished surface. The optical device for metal surface polishing, provided by the invention, realizes polishing on the metal surface by controlling related femtosecond laser machining parameters. Compared with an existing mechanical polishing method, one-time large-area quick polishing and micro-area polishing can be realized without abrasive paper, abrasive paste, chemical corrosive agents and other auxiliary materials. Moreover, the whole machining process is simple and easy to operate, the thermal effect can be neglected, and the high-precision polishing effect can be achieved. Meanwhile, through non-contact machining, damage, contamination and the like of stress to the surface of metal tungsten sample can be effectively avoided.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

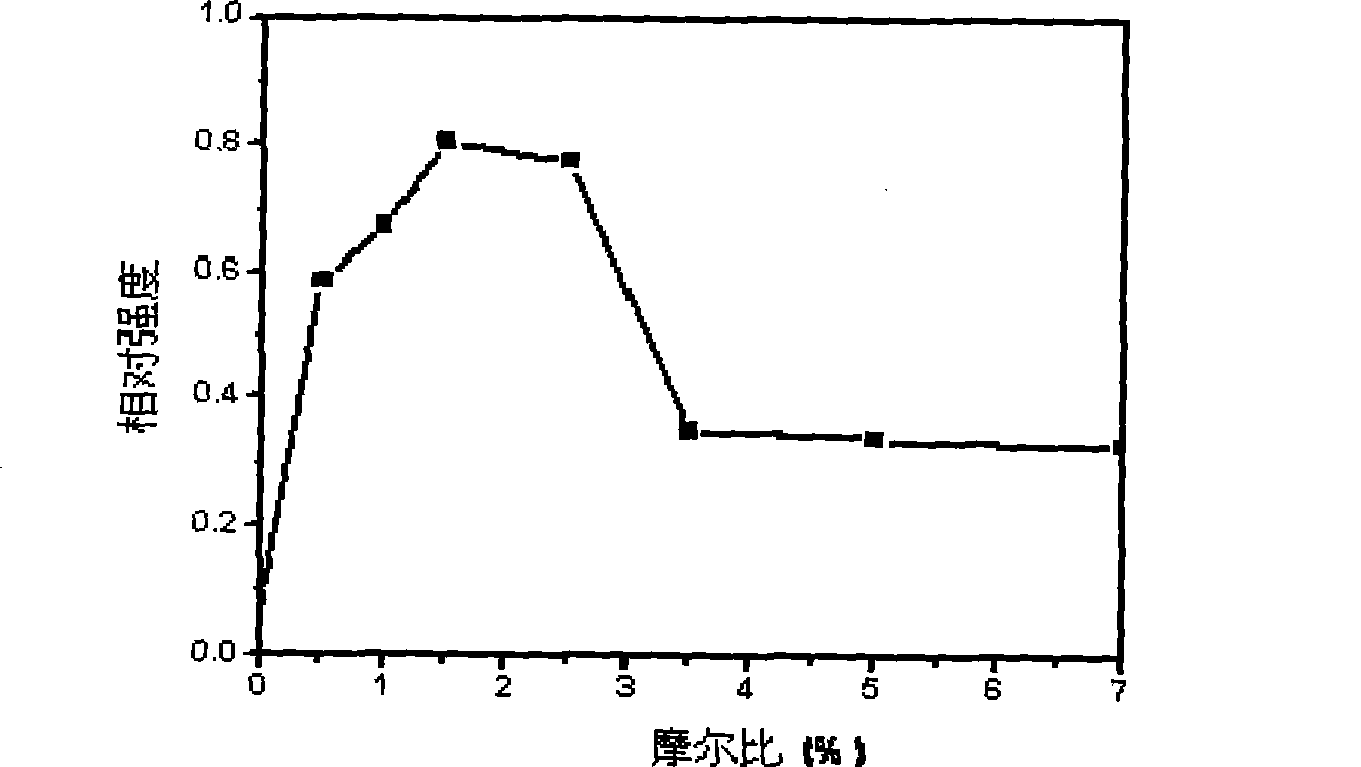

Metal nanoparticle-doped yttrium vanadate luminescent material and preparation method thereof

InactiveCN104059667AImprove luminous efficiencyWavelength does not changeLuminescent compositionsMetal particleLength wave

The invention discloses a metal nanoparticle-doped yttrium vanadate luminescent material and a preparation method thereof, belonging to the field of luminescent materials. The general chemical formula of the luminescent material is Y1-x-yVO4:Eux,Aly,Mz, wherein M is at least one selected from metal nanoparticles consisting of Ag, Au, Pt, Pd and Cu, x is more than 0 and no more than 0.2, y is more than 0 and no more than 0.1, and z is the mol ratio of M to Y1-x-yVO4:Eux,Aly and is more than 0 and no more than 1 * 10<-2>. In the metal nanoparticle-doped yttrium vanadate luminescent material, the M metal particle is introduced, so the yttrium vanadate luminescent material has greatly improved luminous efficiency under same excitation conditions and the wavelength of emitted light is not changed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

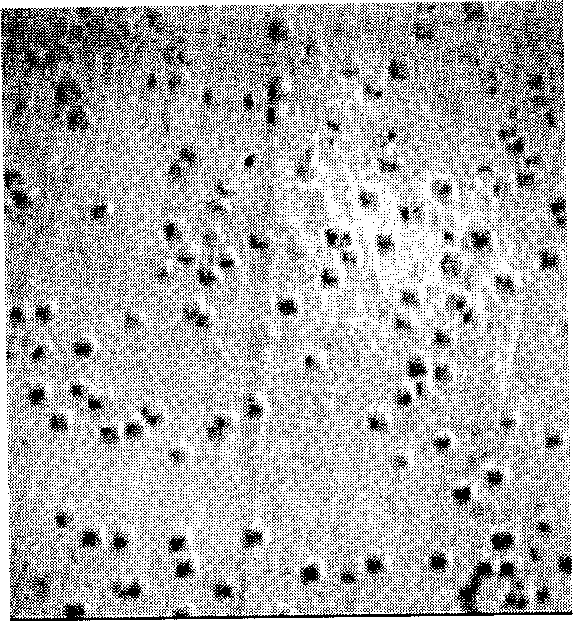

Vanadate for measuring dislocation density and etching process of doped monocrystal

InactiveCN1366098APolycrystalline material growthAfter-treatment detailsHydrofluoric acidPhosphoric acid

An etching process for vanadate and doped monocrystal used to measure dislocation density includes polishing the vanadate (yttrium vanadate or gadolinium vanadate) and doped rare-earth monocrystal, then immersing in etching liquid containing concentrated phosphoric acid and hydrofluoric acid in vol ratio of 100 (0-10) at 60-180 deg.c for 1-30 min, flushing, drying by rubbing, observing dislocation etched pit, and measuring and testing. It can be used for judging the quality of crystal.

Owner:BEIJING UNIV OF TECH

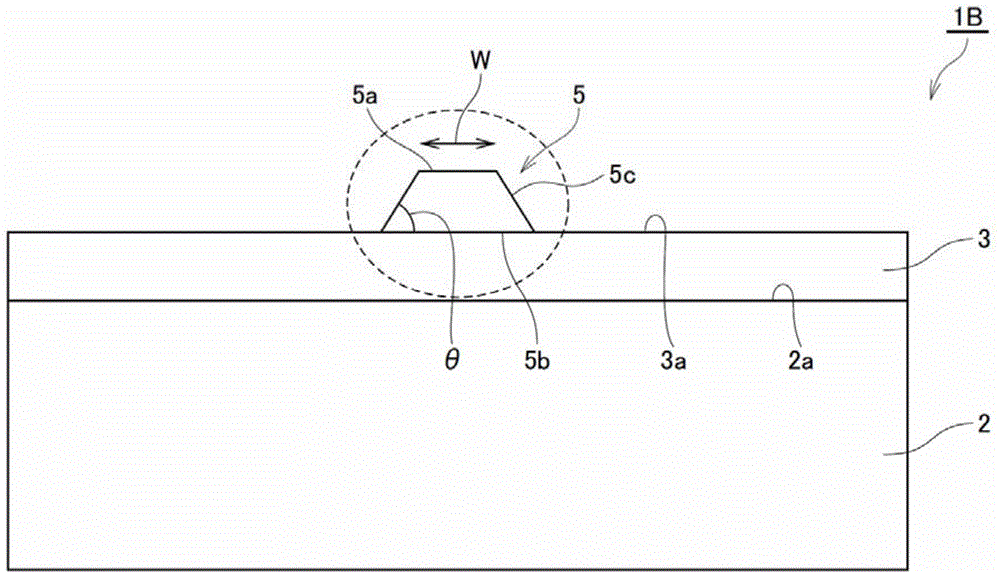

Optical Waveguide Devices

ActiveUS20150147038A1Design freedomReduced propagation lossOptical waveguide light guideNon-linear opticsTungstatePotassium

An optical waveguide device 1 includes a thin layer 3 and a ridge portion 5 loaded on the thin layer 3. The thin layer 3 is made of an optical material selected from the group consisting of lithium niobate, lithium tantalate, lithium niobate-lithium tantalate, yttrium aluminum garnet, yttrium vanadate, gadolinium vanadate, potassium gadolinium tungstate; and potassium yttrium tungstate. The ridge portion 5 is made of tantalum pentoxide and has a trapezoid shape viewed in a cross section perpendicular to a direction of propagation of light. The ridge portion is not peeled off from the thin layer in a tape peeling test.

Owner:NGK INSULATORS LTD

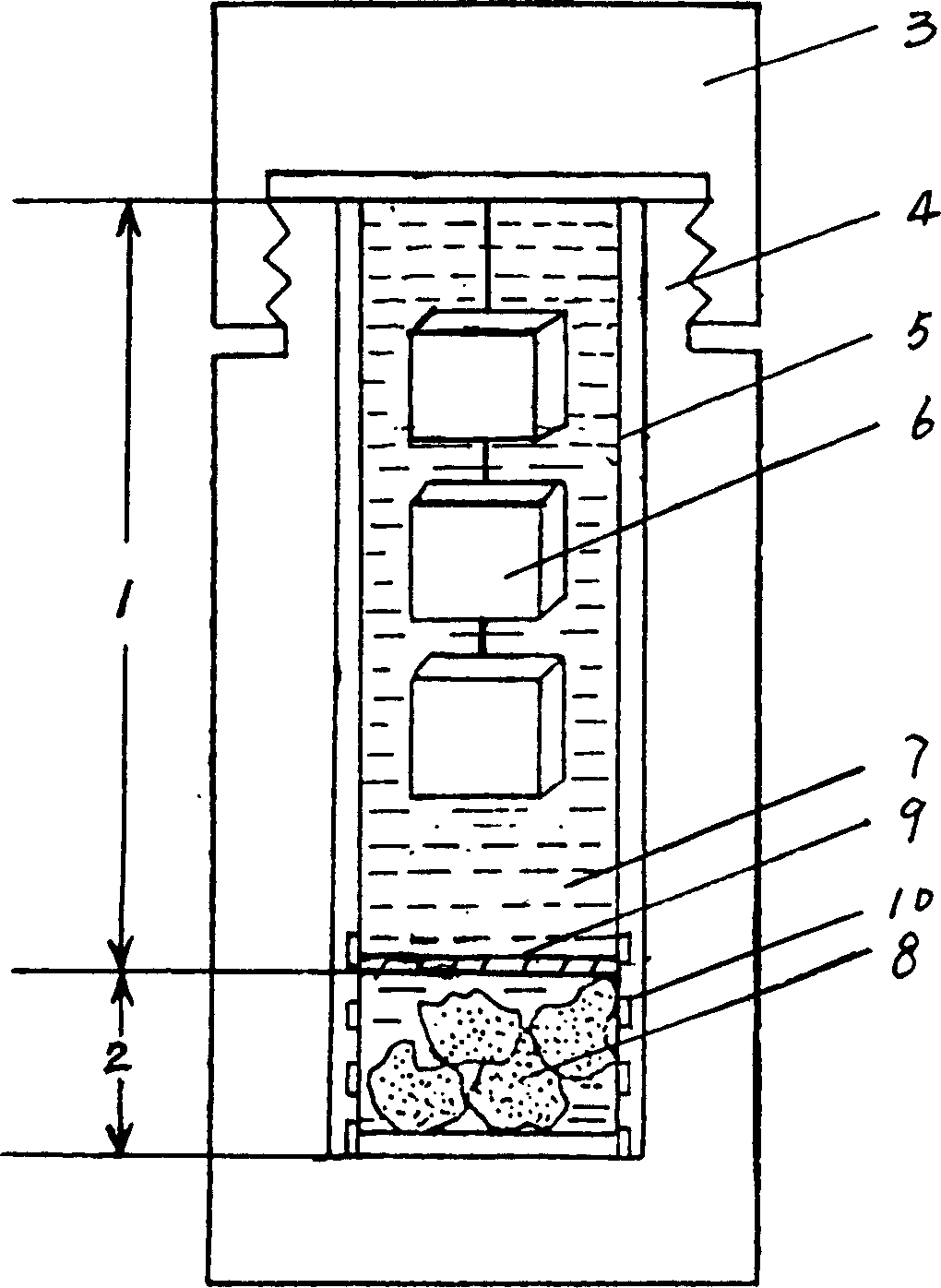

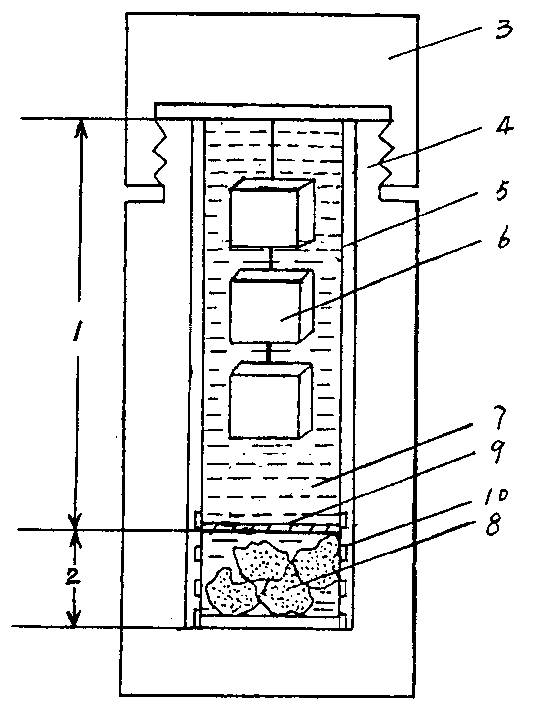

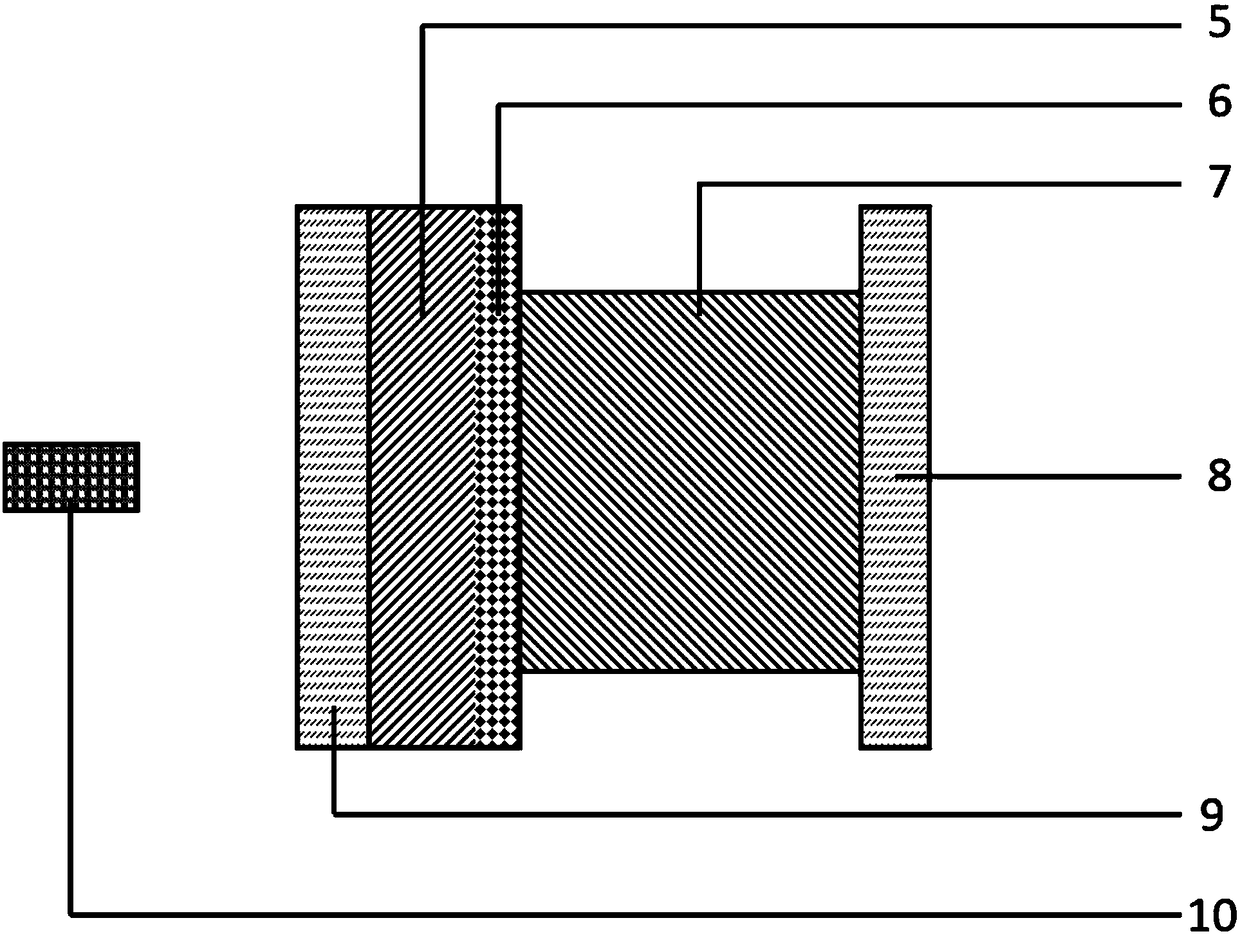

Liquid-phase automatic synthesis reactor of yttrium vanadate

InactiveCN103203209AQuality improvementImprove efficiencyChemical/physical/physico-chemical stationary reactorsVanadium compoundsChemical synthesisFiltration

The invention discloses a liquid-phase automatic synthesis reactor of yttrium vanadate. The liquid-phase automatic synthesis reactor can be used for the liquid-phase chemical synthesis of yttrium vanadate, and is especially suitable for the raw material synthesis of czochralski method growth yttrium vanadate and crystals doped therein. The intelligent synthesis reactor is composed of an automatic feeding zone, a raw material dissolving zone, a pumping-filtration impurity-removal zone, a synthetic reaction zone and a PLC intelligent control device. The liquid-phase automatic synthesis reactor can realize the streamline production comprising the operations of intelligent control, automatic feeding, raw material dissolving, pumping-filtration impurity-removal, and synthetic reaction of the whole raw material preparation process, has the characteristics of intelligence, saving, environmental protection, high efficiency, stability, reliability and the like, and can strongly push forward the standardized and large-scale development of the crystal industry.

Owner:FUJIAN CASTECH CRYSTALS

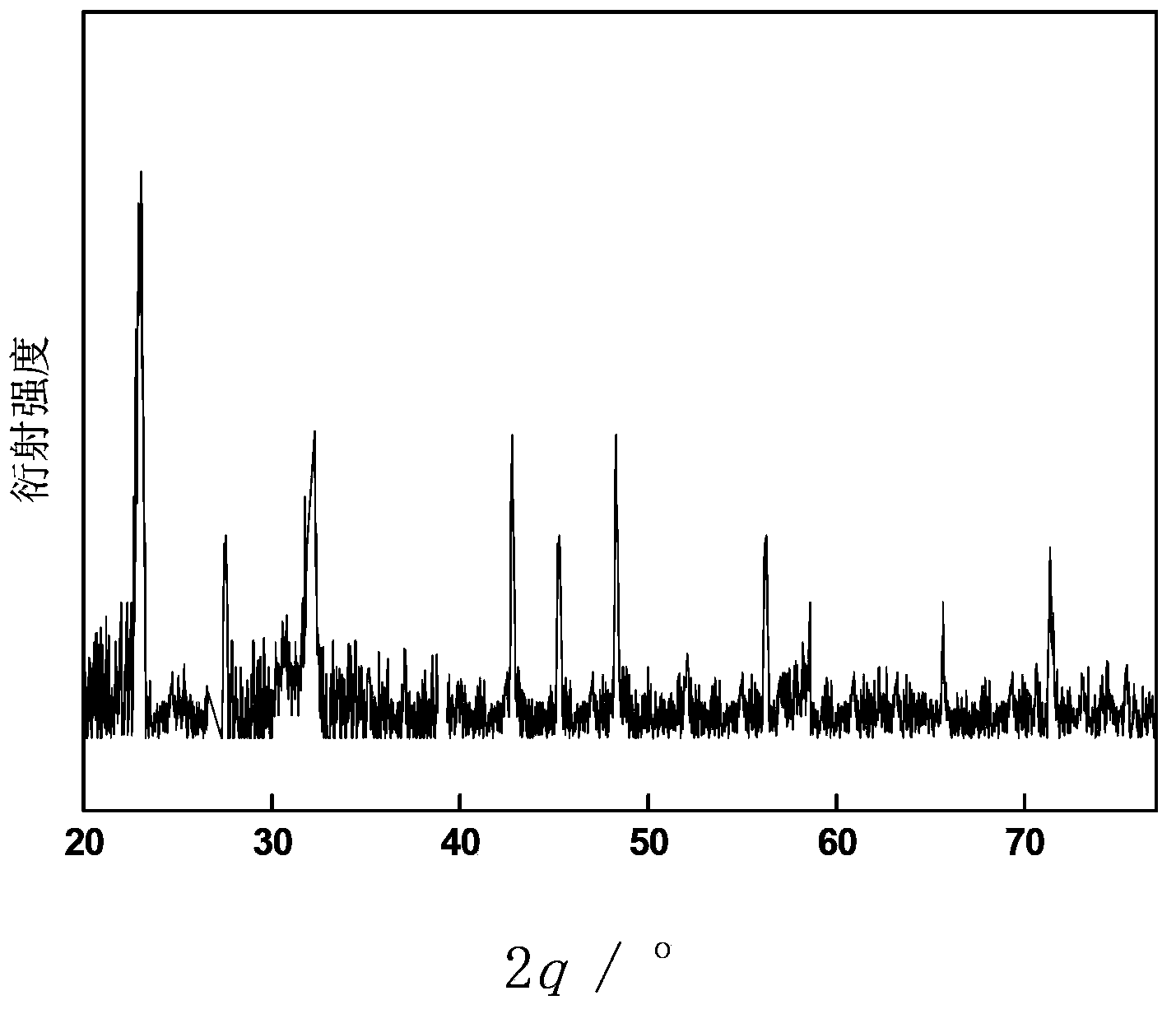

Preparation method of yttrium vanadate transparent ceramic

A preparation method of an yttrium vanadate transparent ceramic comprises the following steps: dissolving yttrium nitrate hexahydrate in deionized water at first, magnetically stirring to obtain an yttrium nitrate aqueous solution, then adding a proper amount of citric acid and ammonium metavanadate, and magnetically stirring to obtain a mixed solution; placing the mixed solution in an oven and evaporating to remove water so as to obtain a brown solid product, breaking the product and then annealing the product in a muffle furnace, and washing and drying the product with dilute nitric acid anddeionized water to obtain yttrium vanadate nano powder; and finally carrying out dry pressing forming on the obtained yttrium vanadate nano powder, and sintering in a pressure-free manner in an air atmosphere to obtain the yttrium vanadate transparent ceramic. The yttrium vanadate ceramic prepared by the invention is high in compactness and good in light transparency, and moreover, the method hasthe advantages of low sintering temperature, simple preparation process, short production period, low cost and the like, and is suitable for industrialized production of a yttrium vanadate transparent ceramic material.

Owner:JIUJIANG UNIVERSITY

Fluorescent lamp with underlying yttrium vanadate phosphor layer and protective phosphor layer

Owner:GENERAL ELECTRIC CO

Method for growing neodymium-doped yttrium vanadate and yttrium vanadate composite laser crystal

InactiveCN1206392CImprove integrityGood repeatabilityPolycrystalline material growthFrom normal temperature solutionsLaser processingSingle crystal

A growth method of neodymium-doped yttrium vanadate and yttrium vanadate composite laser crystals, which is formed by growing non-doped yttrium vanadate single crystals at both ends of neodymium-doped yttrium vanadate single crystals by using a hydrothermal growth furnace, and the crystal integrity Well, it is cut and processed to make a laser, which has broad application prospects in the field of miniaturized, high-efficiency, and low-threshold solid-state lasers.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

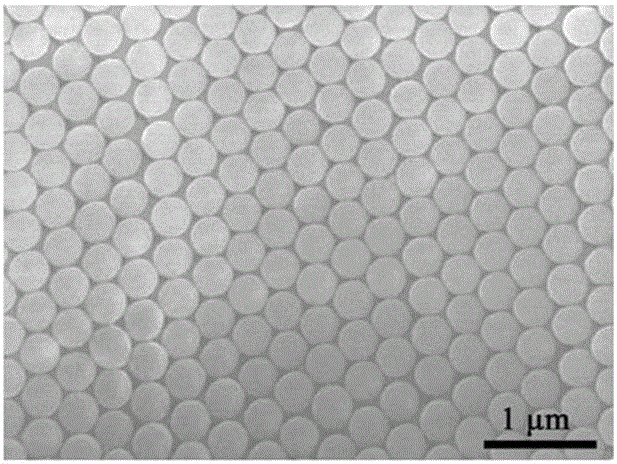

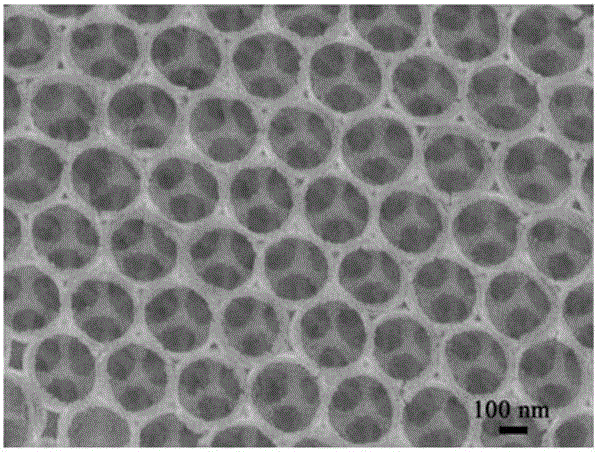

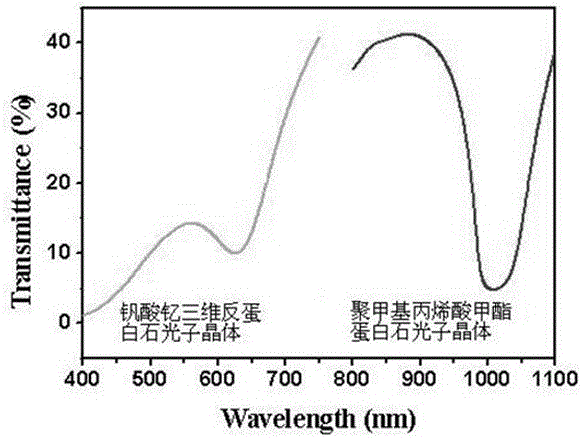

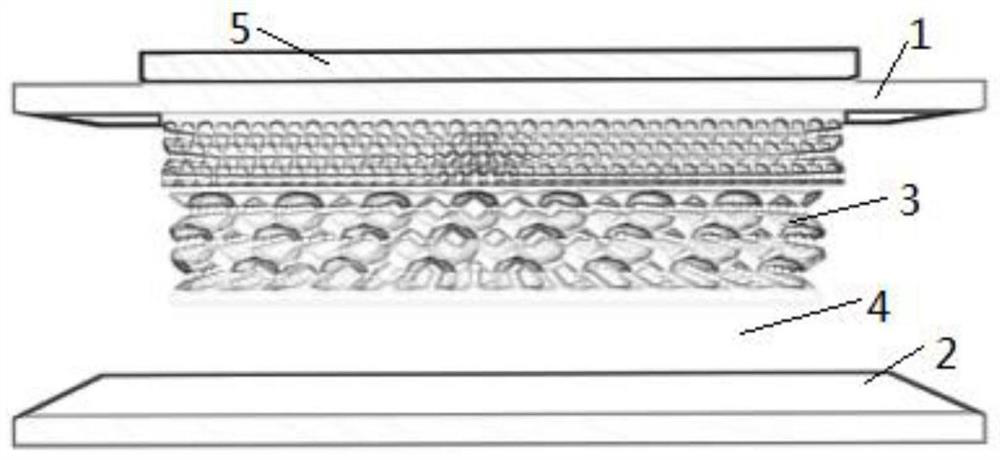

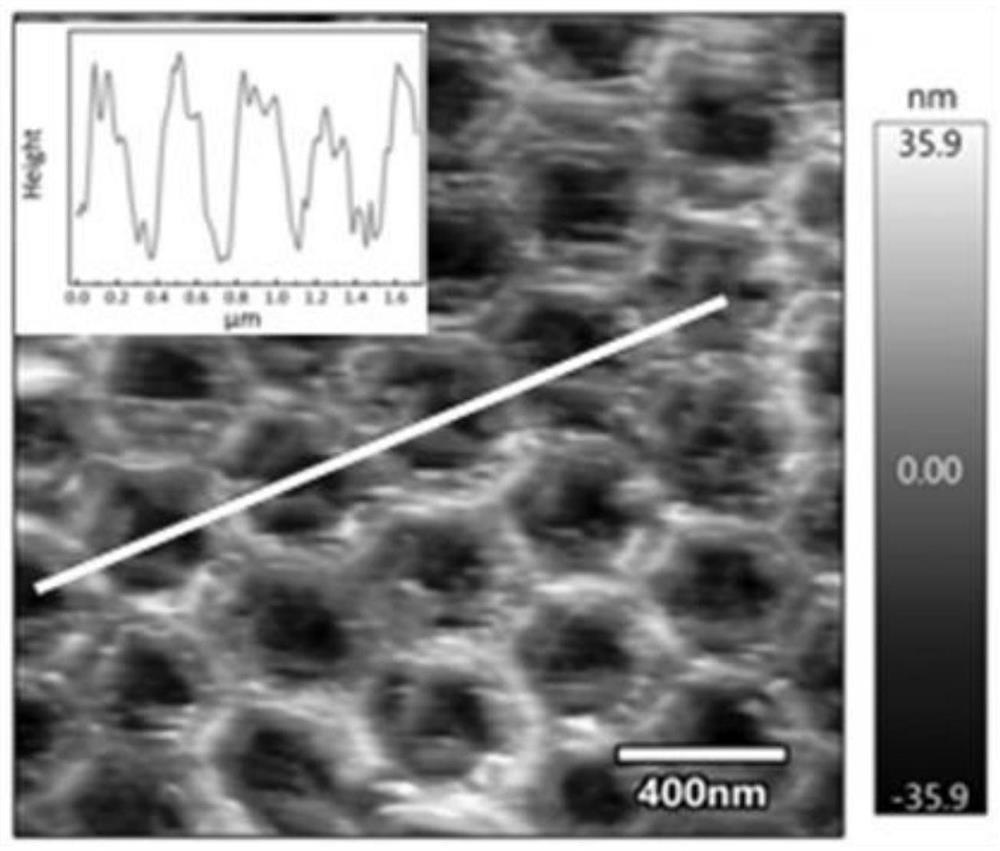

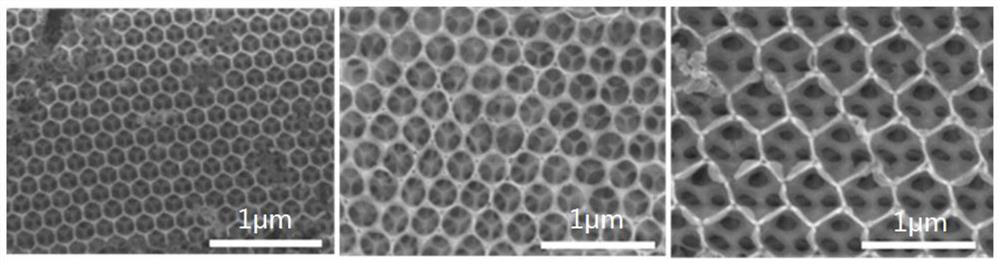

Preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal

InactiveCN106835281AUniform structurePhotonic bandgap precisionPolycrystalline material growthFrom normal temperature solutionsLaser etchingPhotonic crystal structure

The invention discloses a preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal. The method comprises the steps of (1) preparing polymethyl methacrylate nanospheres; (2) growing an opal structure photonic crystal; (3) preparing an inverse opal photonic crystal precursor solution; and (4) sintering the inverse opal photonic crystal. Compared with a laser etching method, the method has the advantages that the prepared photonic crystal is uniform in structure, accurate in photonic band gap and low in preparation cost, and the method can be used for massive production of the photonic crystal.

Owner:NANYANG NORMAL UNIV

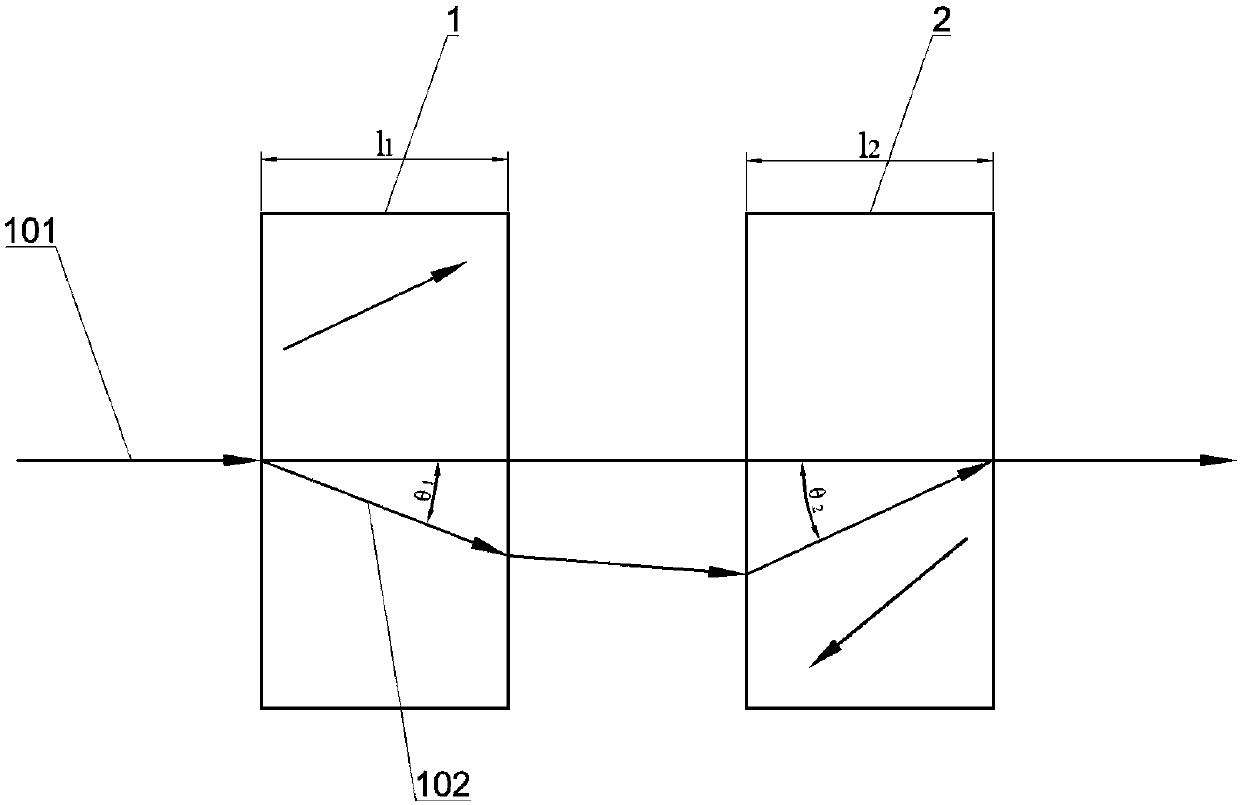

Device for improving spot quality of non-linear crystal frequency-conversion laser

PendingCN107561814AImprove spot qualityEasy to operateNon-linear opticsOptical powerUniaxial crystal

The invention discloses a device for improving spot quality of non-linear crystal frequency-conversion laser. The device comprises a non-linear crystal unit and a walk-off compensation crystal unit, wherein the non-linear crystal unit comprises a non-linear crystal which is composed of beta-barium borate crystals or caesium lithium borate; the walk-off compensation crystal unit comprises an uniaixal crystal which is composed of yttrium vanadate crystals or alpha-barium borate crystals. The device for improving the spot quality of the non-linear crystal frequency-conversion laser performs compensating and shaping treatment on laser spots frequency-converted by the non-linear crystal through the walk-off compensation crystal to obtain round laser spots under the premise of not losing the optical power of converting laser, thereby improving the spot quality. Meanwhile, the device for improving the spot quality of the non-linear crystal frequency-conversion laser is simple in operation, significant in effects, low in cost and capable of solving the technical problem of quality reduction of output laser spots.

Owner:福建科彤光电技术有限公司

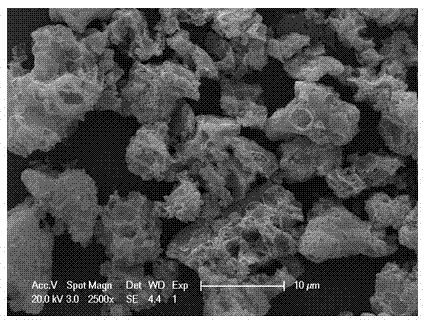

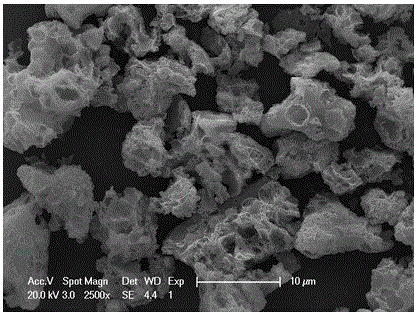

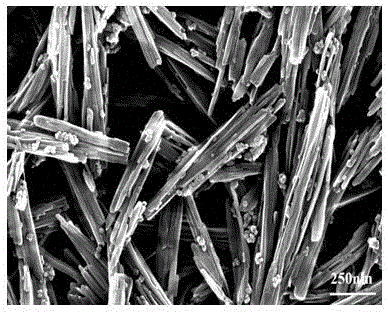

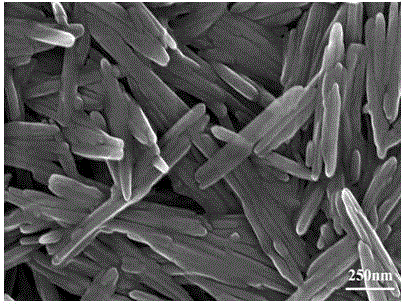

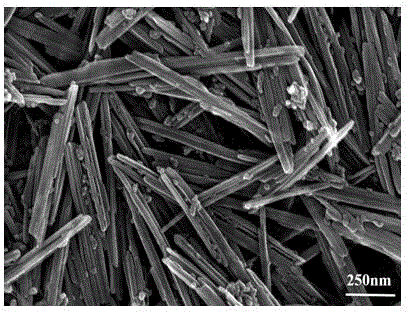

Preparation method of porous nano material yttrium vanadate

ActiveCN105439199ALarge specific surface areaFast responseNanotechnologyVanadium compoundsForming gasReaction rate

The invention discloses a preparation method of a porous nano material yttrium vanadate. The preparation method comprises the following steps: firstly, preparing nano carbon spheres; then covering surfaces of the nano carbon spheres with a layer of a yttrium vanadate nano material by applying a citric acid complexing method by taking the nano carbon spheres as a template; and calcining the carbon spheres to generate CO2 gas which breaks through yttrium vanadate covering the surfaces of the carbon spheres to form gas holes on the surface of yttrium vanadate so as to generate the porous nano material yttrium vanadate. The porous nano material YVO4 disclosed by the invention has a relatively large specific area which can reach 14.37m<2> / g and is nearly four times greater than that of YVO4 not doped with carbon spheres, and the relatively large specific area can improve the reaction rate and efficiency of a pholocatalyst.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Process for synthesizing yttrium n-vanadate and its derivative

A method for synthesizing yttrium orthovanadate and its derivatives is the low-temperature self-assembly solid-phase synthesis of yttrium orthovanadate and its derivatives in the presence of a template, including mixing and grinding, drying and loading, pre-sintering and grinding. sampling, burning and washing and drying steps. The method has the advantages of low cost, low energy consumption, low requirements for production equipment configuration, and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

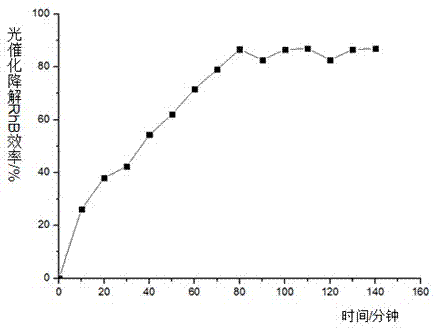

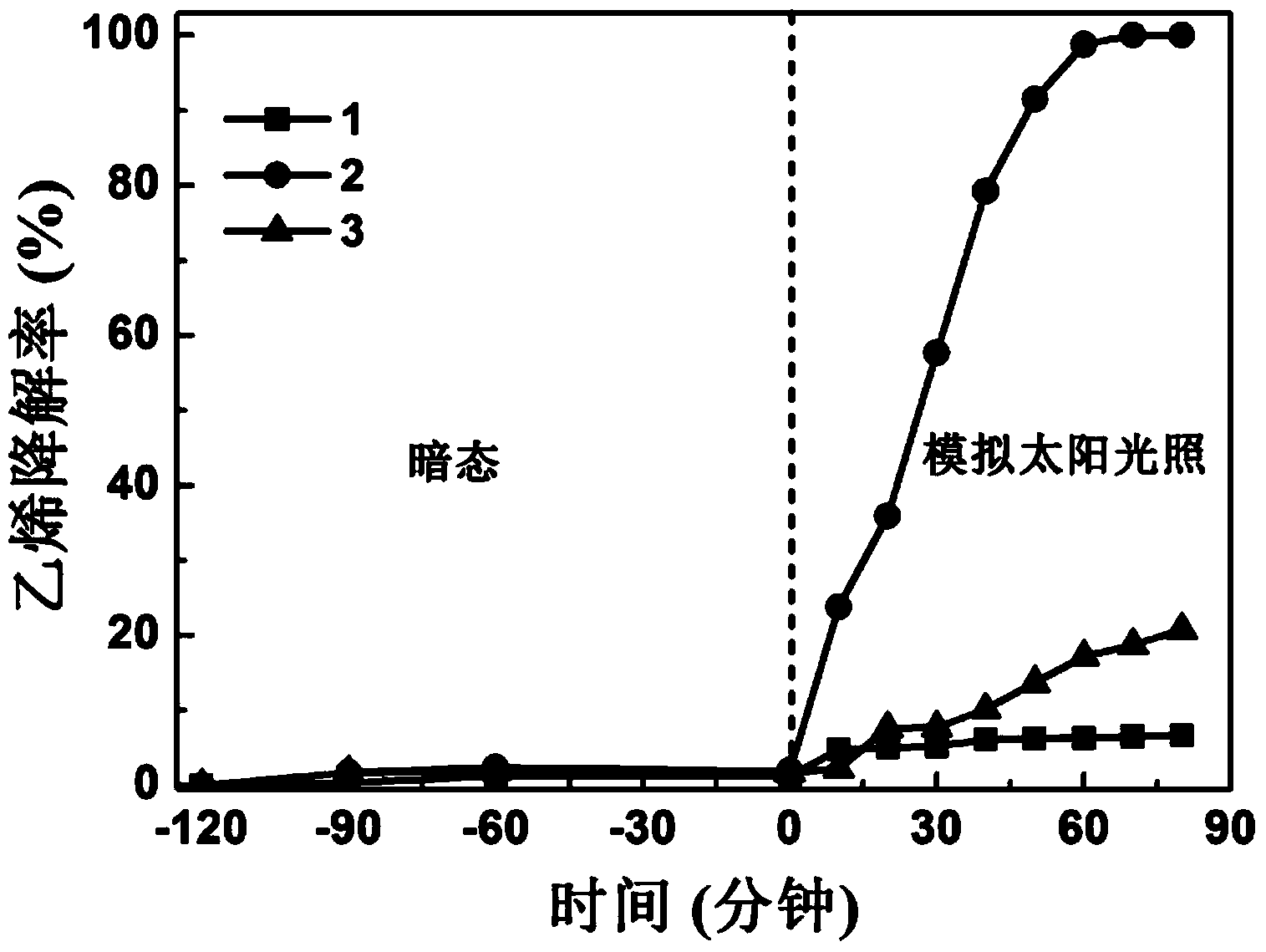

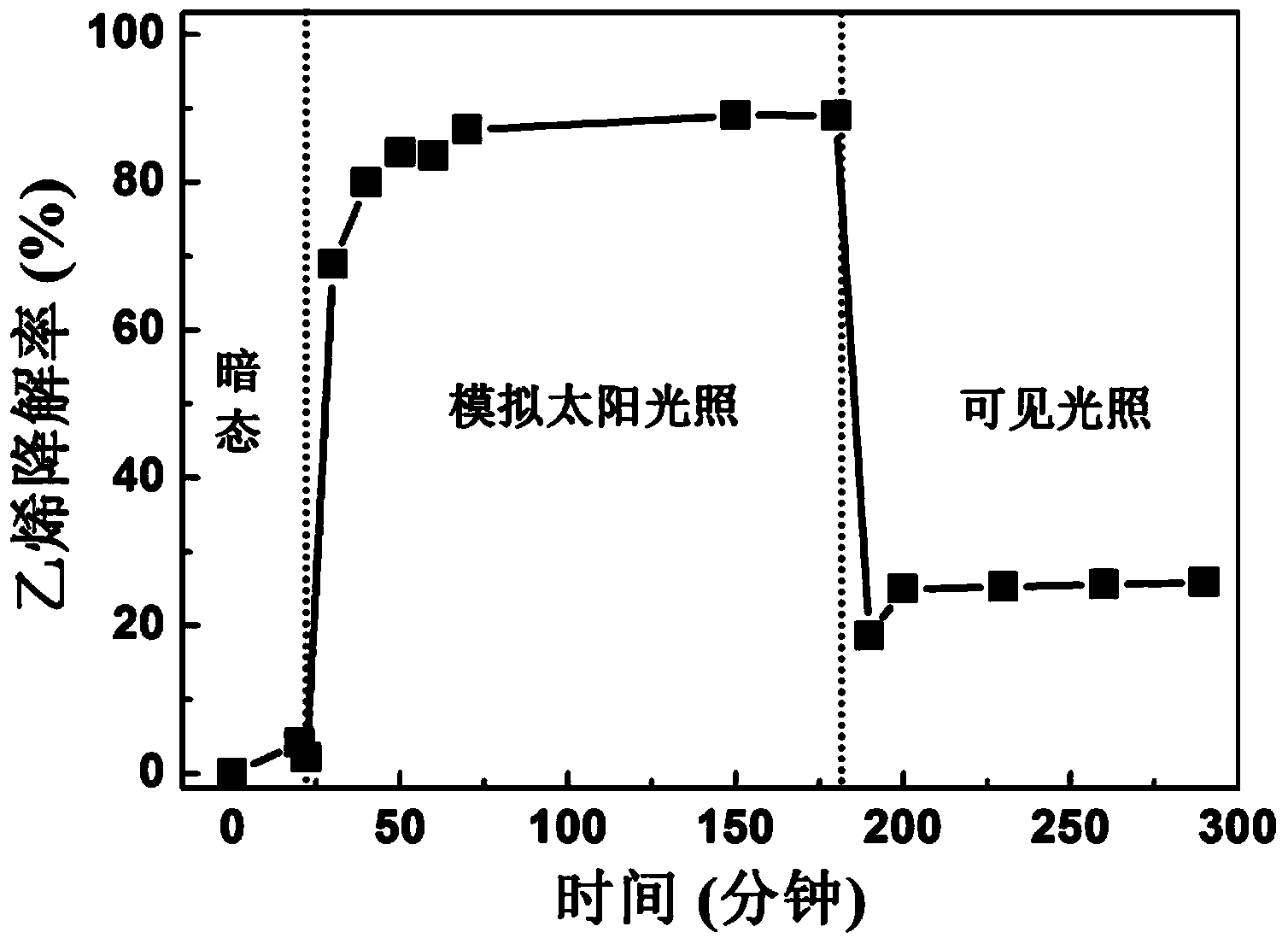

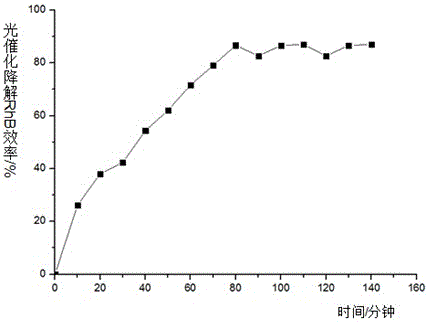

Bismuth-doped yttrium vanadate semiconductor for photocatalytic degradation of ethylene

InactiveCN103585884AImprove practicalityDispersed particle separationPhotocatalytic degradationVanadate

The invention relates to a bismuth-doped yttrium vanadate semiconductor for photocatalytic degradation of ethylene. A bismuth-doped yttrium vanadate photocatalyst is low in cost, high in photocatalytic activity and good in stability, a static bed and a fluid bed can efficiently perform the photocatalytic degradation on ethylene under simulated sunlight irradiation, and the photocatalyst is very easy to collect and recycle, and has a good application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

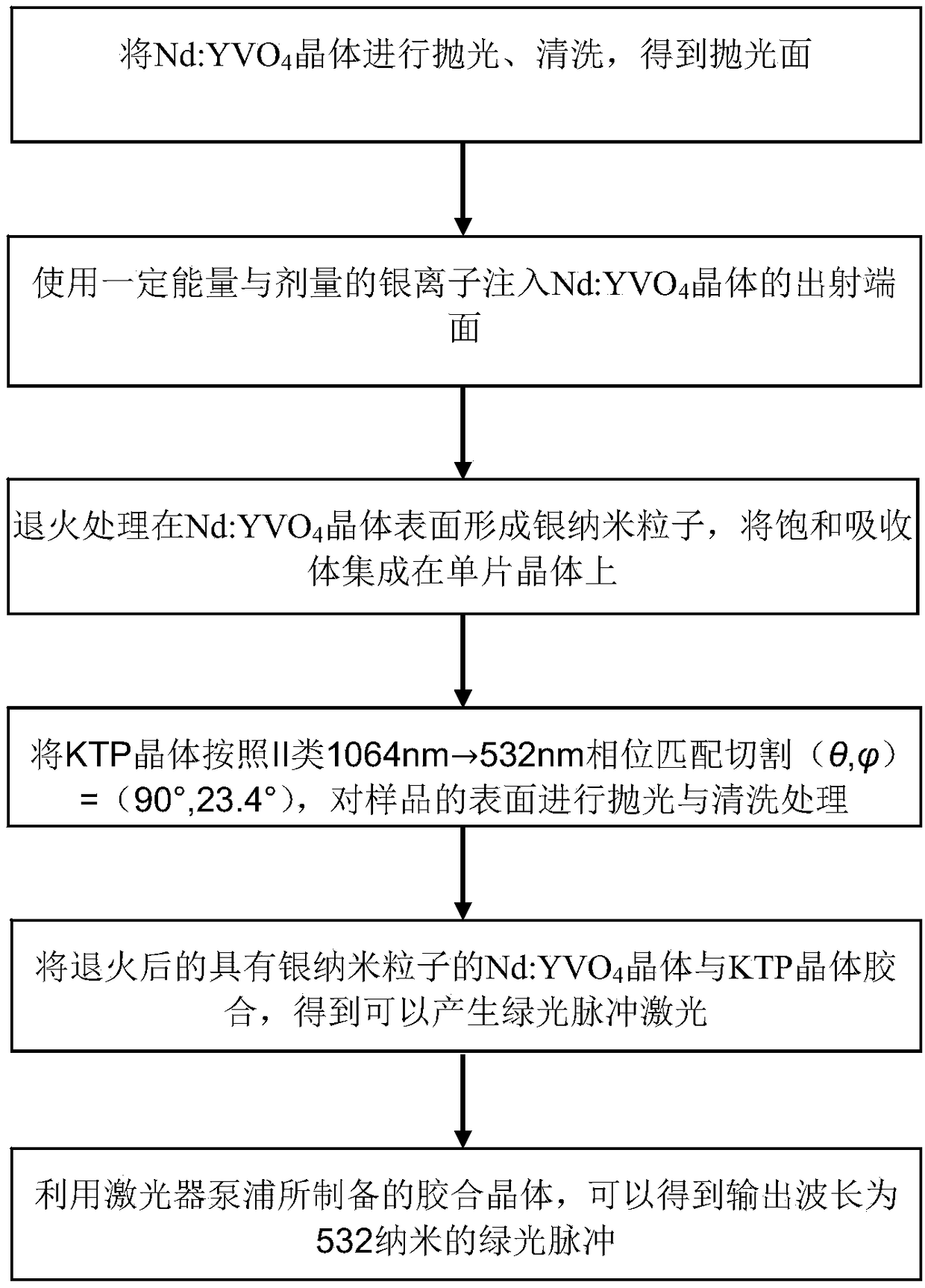

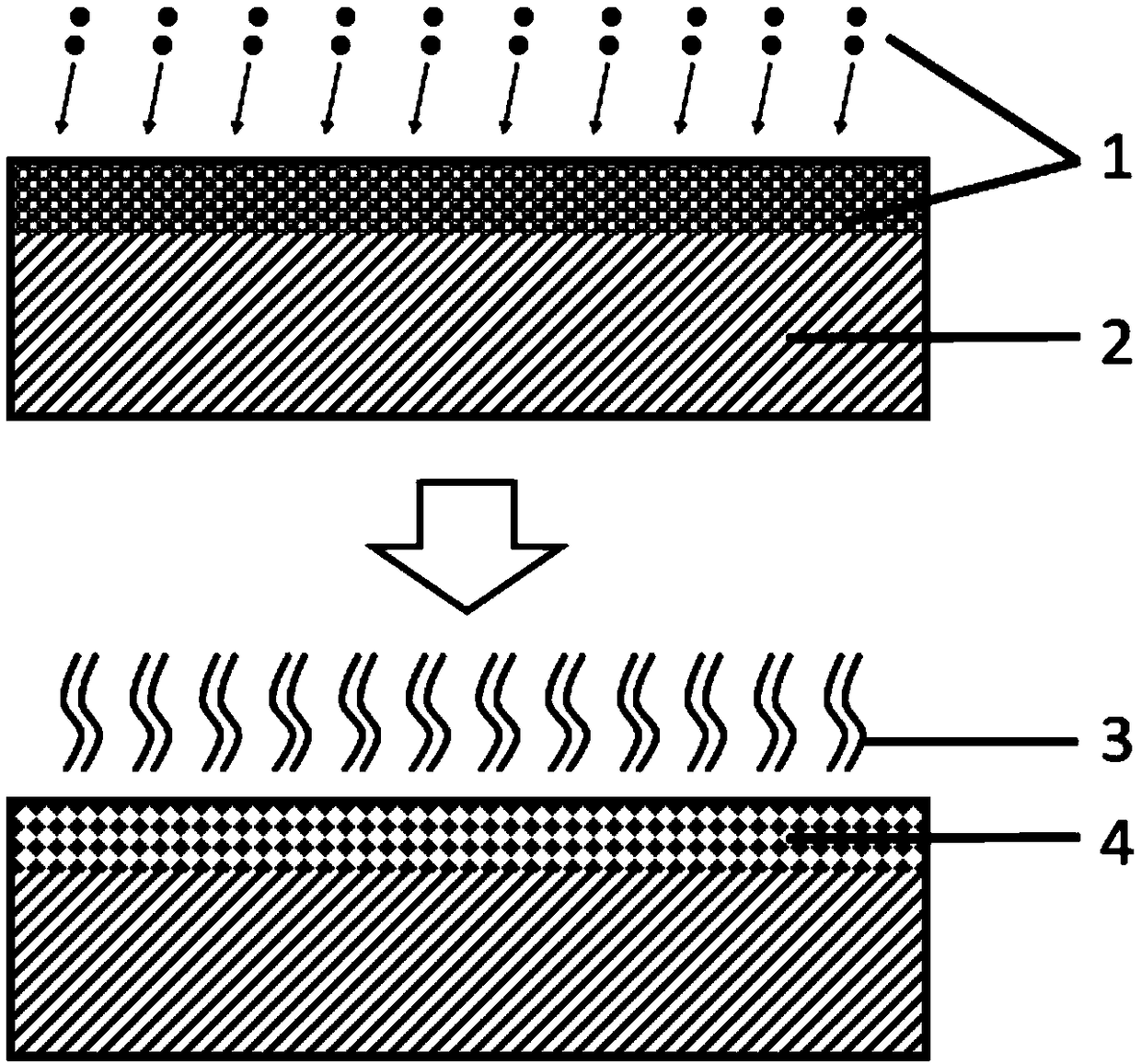

A monolithic integrated green pulse laser based on neodymium doped yttrium vanadate and potassium titanium oxyphosphate bonding crystal and preparation method thereof

InactiveCN109217091AHigh peak powerIncrease brightnessActive medium materialPotassiumPhosphoric acid

The invention relates to a monolithic integrated green pulse laser based on neodymium doped yttrium vanadate and potassium titanium oxyphosphate gluing crystal and preparation thereof, wherein, the energy-carrying ion beam technology and the plasmon resonance effect are applied, and the injection energy of 100 DEG C and 100 DEG C is used as the injection energy of 100 DEG C and 100 DEG C respectively. A metal nanoparticle-based saturable absorption mirror is integrate into a Nd: YVO4 laser crystal at a dose of (1- 10) * 1016 ion / cm2 for producing a pulsed laser at a wavelength of about 1 micron. The prepared Nd: YVO_4 crystals were bonded or photocolloidally bonded to the KTP crystals which satisfy the phase matching of class II 1064 nm - 532 nm to form a miniaturized integrated device which can generate 532 nm green laser pulses. The invention has the advantages of high conversion efficiency, good beam quality, long service life, convenient use and the like, and can generate green light pulses with high peak power and high brightness, and has important applications in color display, laser processing, laser medical treatment, stylus and the like.

Owner:SHANDONG UNIV

Vanadate for measuring dislocation density and etching process of doped monocrystal

InactiveCN1142330CPolycrystalline material growthAfter-treatment detailsHydrofluoric acidPhosphoric acid

An etching process for vanadate and doped monocrystal used to measure dislocation density includes polishing the vanadate (yttrium vanadate or gadolinium vanadate) and doped rare-earth monocrystal, then immersing in etching liquid containing concentrated phosphoric acid and hydrofluoric acid in vol ratio of 100 (0-10) at 60-180 deg.c for 1-30 min, flushing, drying by rubbing, observing dislocation etched pit, and measuring and testing. It can be used for judging the quality of crystal.

Owner:BEIJING UNIV OF TECH

A kind of preparation method of porous nano material yttrium vanadate

ActiveCN105439199BLarge specific surface areaFast responseNanotechnologyVanadium compoundsForming gasReaction rate

The invention discloses a method for preparing porous nanomaterial yttrium vanadate. First, nanocarbon balls are prepared, using the nanocarbon balls as templates, and using the citric acid complexing method to coat the surface of the nanocarbon balls with a layer of yttrium vanadate nanomaterials. CO2 gas is generated by calcining the carbon balls, and the CO2 gas breaks through the yttrium vanadate covered on the surface of the carbon balls, forming pores on the surface of the yttrium vanadate, generating porous nanomaterial yttrium vanadate. The nanoporous material YVO4 of the present invention has a large specific surface area, and its specific surface area can reach 14.37m2 / g, which is nearly four times larger than the specific surface area of YVO4 without carbon ball doping. The large specific surface area can improve the light Catalyst reaction rate and efficiency.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

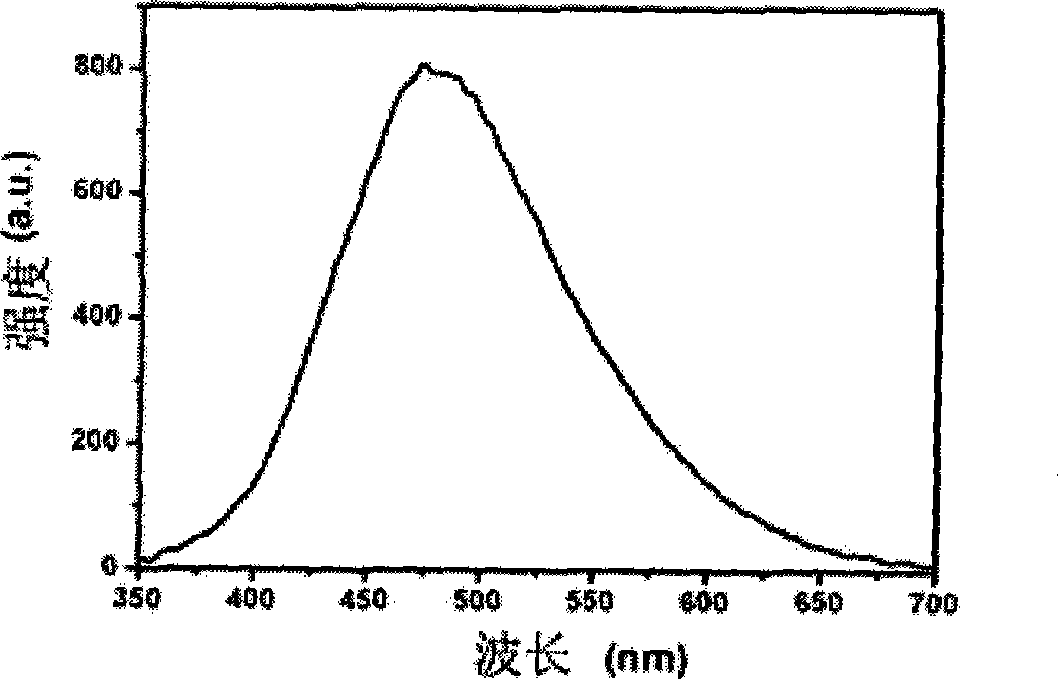

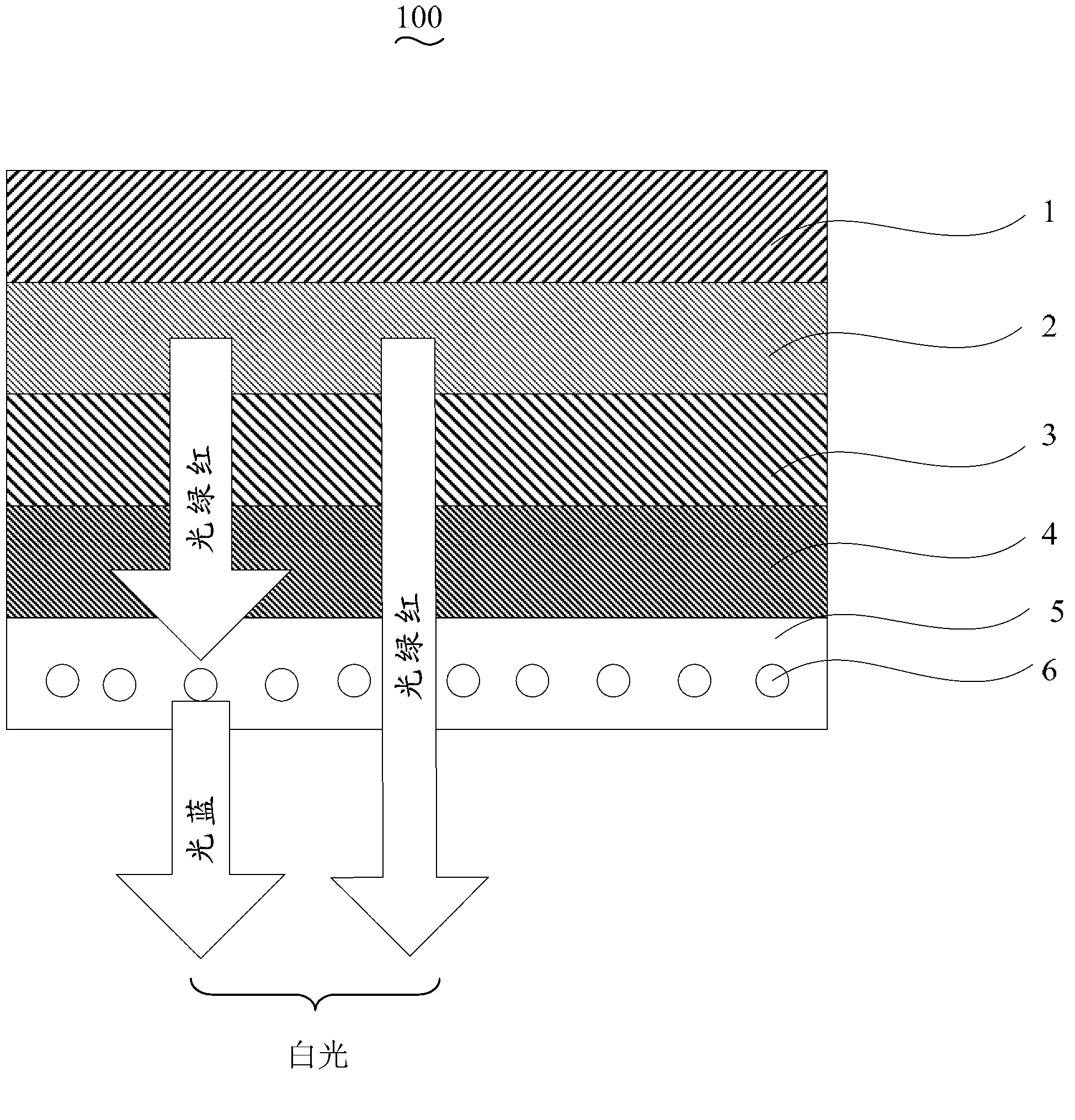

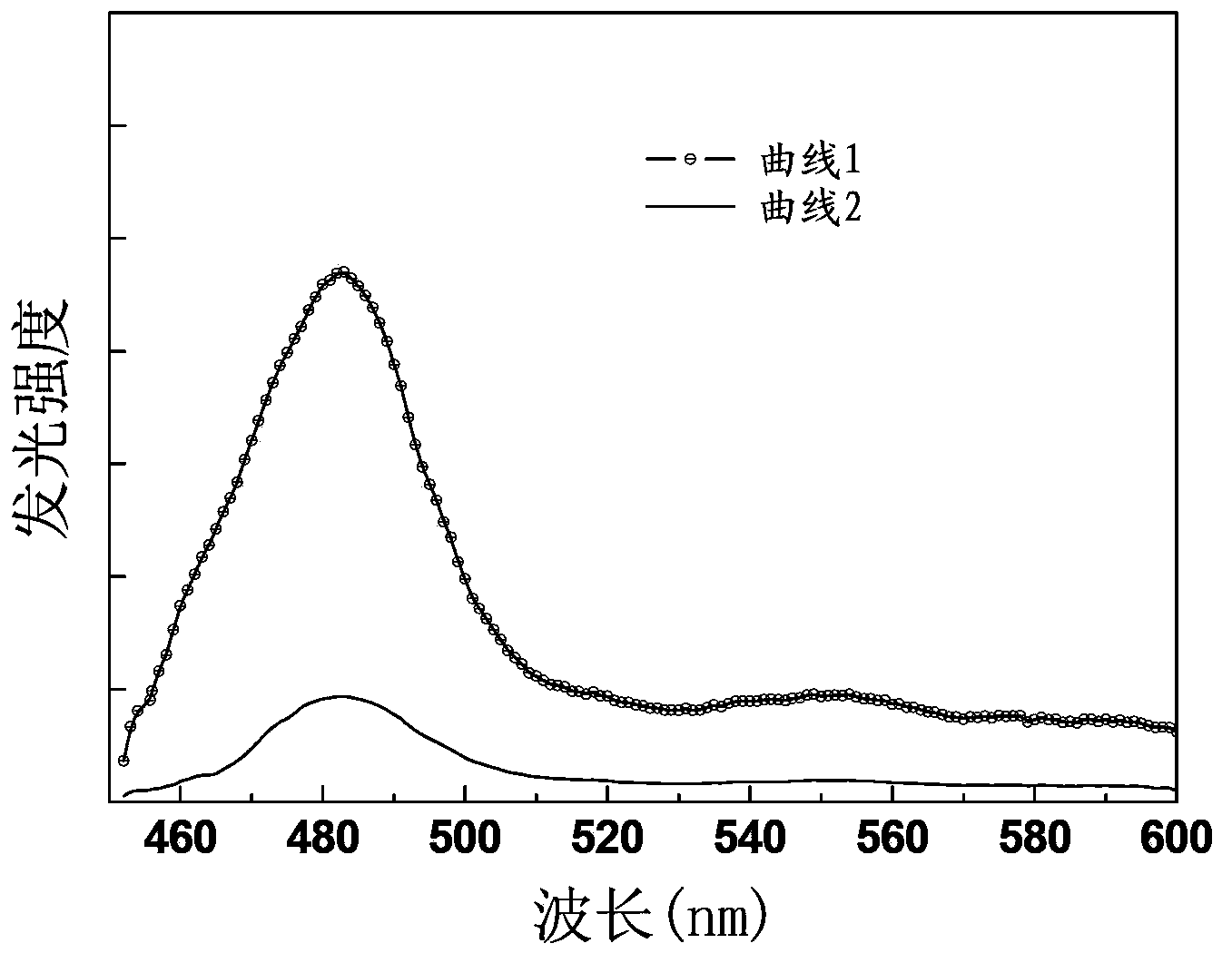

Praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material and preparation method and application thereof

InactiveCN103805197ASolid-state devicesSemiconductor/solid-state device manufacturingPhotoluminescenceTransition radiation

The invention discloses a praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material with a chemical general formula of Y(1-x-y)VO4:xPr<3+>, yYb<3+>, wherein x is 0.01-0.08 and y is 0-0.1. In the photoluminescence spectrum of the praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material, the excitation wavelength of the praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material is 980nm, the transition radiation from <3>P0 to <3>H4 of the Pr<3+> ion forms a luminescence peak in the 485nm wavelength area, and the praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material can be used as a blue light luminescent material. The invention also provides a preparation method of the praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material and an organic LED (light emitting diode) using the praseodymium-ytterbium co-doped yttrium vanadate up-conversion luminescent material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

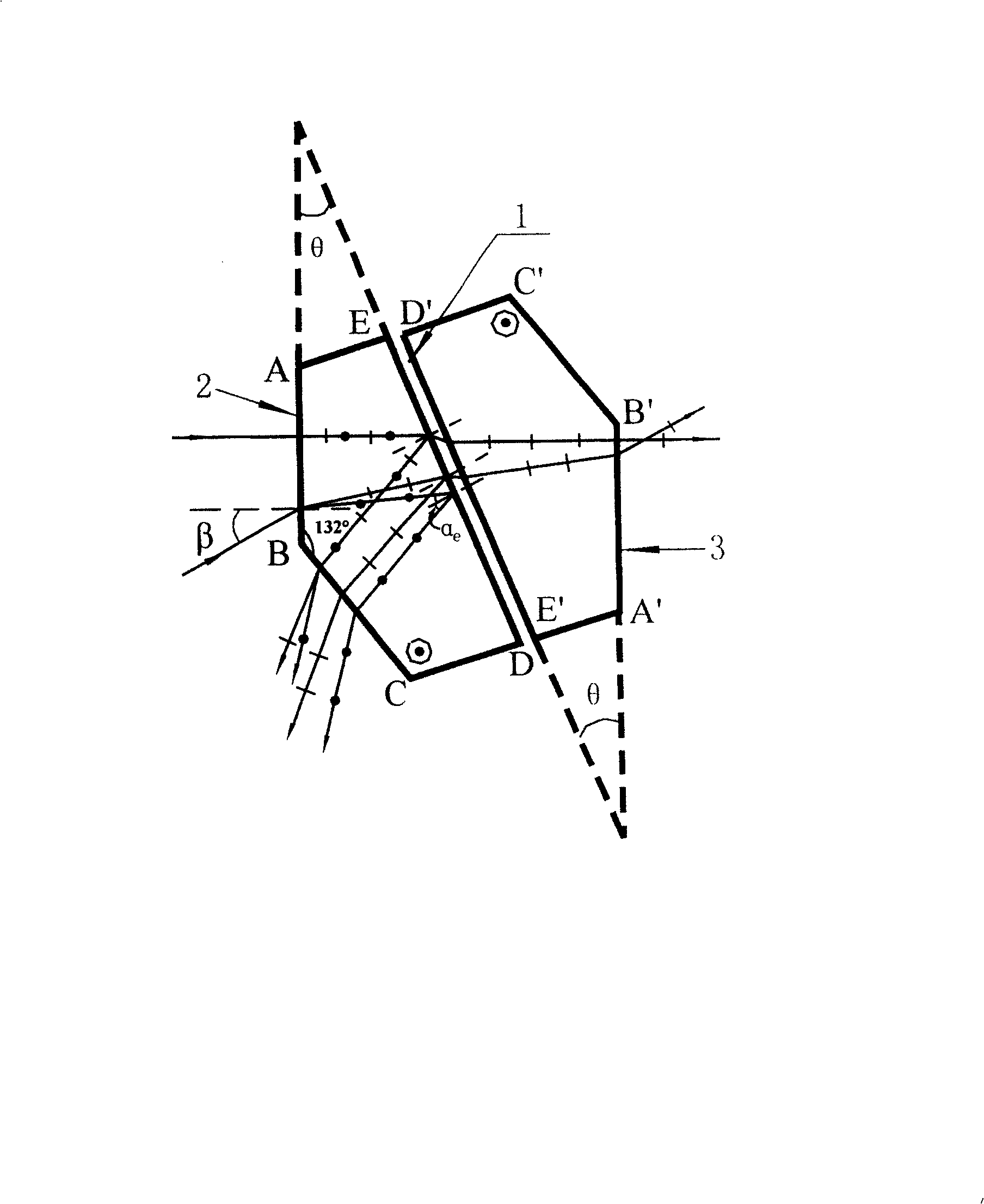

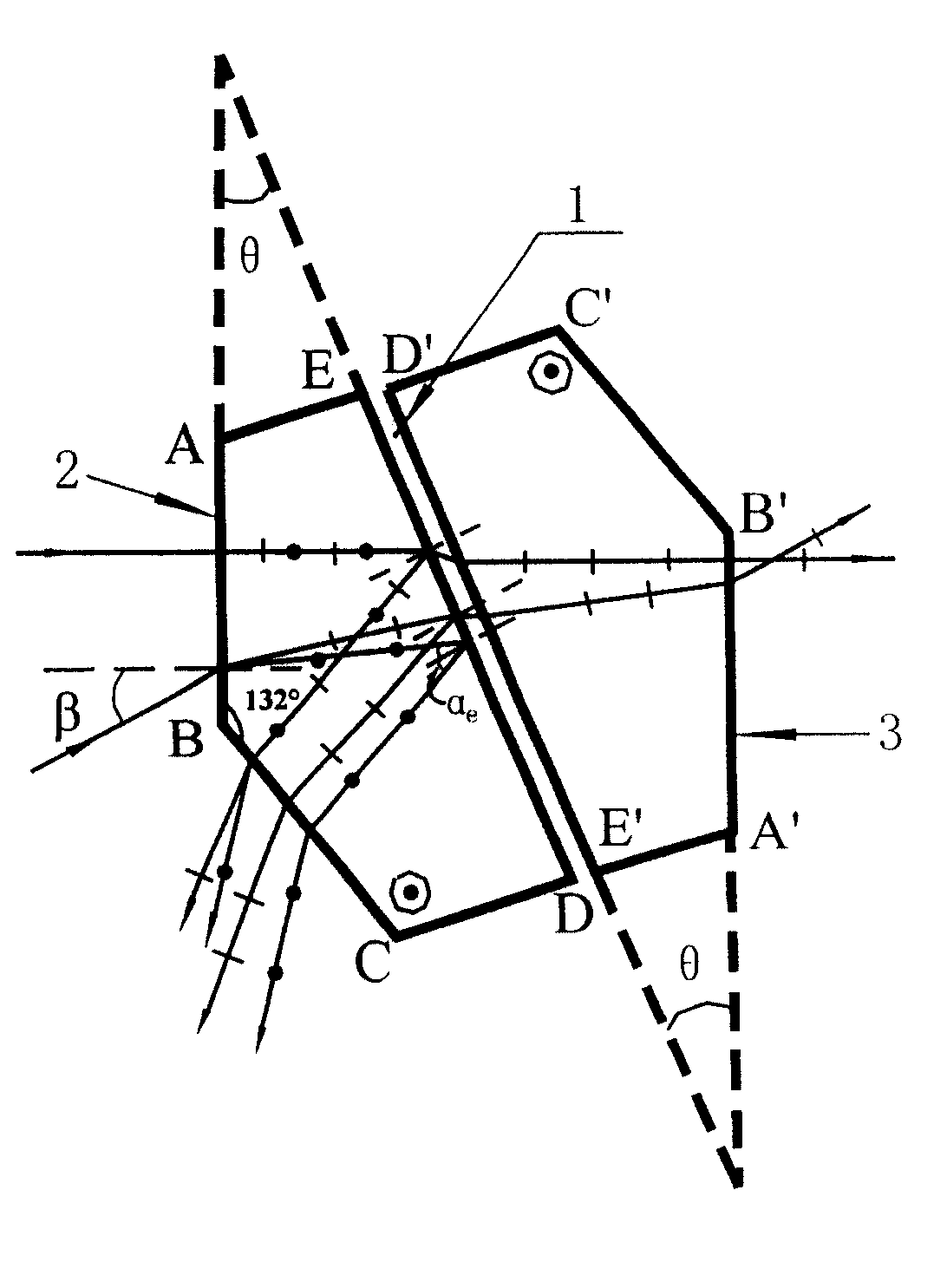

Polarized prism made of yttrium vonadate crystal

InactiveCN100429535CHigh damage thresholdPromote growthPrismsPolarising elementsSlow lightLight beam

A polarizing prism mad eof YVO4 crystal features that its angle theta must be greater than alpha e but less han alpha o to ensure full reflection of slow light on air gap interface, a high-safety polarizing angle beta must exist to ensure complete linear polarization of outgoing light, and the fast light must have the transmission rate at air gap interface as high as passible. Its advantages are with transmission range, great birefringence, high optical uniformity, low temp coefficient, and high hardness.

Owner:青岛海泰光电技术有限公司

Composite metal ceramic material

InactiveCN106699148AImprove high temperature resistanceImprove bending strengthAluminum magnesium silicateTemperature resistance

The invention discloses a composite metal ceramic material. The composite metal ceramic material is prepared from the following raw materials in parts by weight: 10 to 20 parts of silicon dioxide, 2 to 5 parts of anhydrous cupric sulfate, 2 to 8 parts of silicon carbide, 5 to 10 parts of kaolin, 1 to 5 parts of quartz sand, 5 to 10 parts of tungsten dioxide, 2 to 5 parts of antimonous oxide, 1 to 5 parts of thorium sulfate, 1 to 3 parts of germanium nitrate, 2 to 5 parts of lanthanum bromide, 5 to 10 parts of aluminum magnesium silicate, 1 to 5 parts of calcium carbonate, 5 to 10 parts of sodium silicate, 2 to 5 parts of fly ash and 1 to 5 parts of yttrium orthovanadate. The composite material has the advantages of better high temperature resistance, bending strength and toughness, easily-obtained raw materials, lower preparation cost and low process conditions; the composite metal ceramic material can better meet the demands of people.

Owner:余姚市益群机械厂

Preparation method of rare-earth yttrium vanadate

The invention discloses a preparation method of rare-earth yttrium vanadate. Yttrium vanadate is of a sarciniform structure and is prepared by the following steps: (1) preparing a mixed suspension: preparing a yttrium nitrate and sodium orthovanadate mixed suspension by deionized water and a surfactant, wherein the molarity of Y<3+> / VO4<3-> is (1-1.2): 1, and the concentration of the surfactant is 0.8-3.2%; (2) enabling hydrothermal reaction: transferring the mixed suspension into a closed container, sealing, then placing in a drying oven for reaction at 150-200 DEG C for 8-24 h, and collecting the solid to obtain sarciniform yttrium vanadate. The preparation method can overcome the shortcomings of troublesome preparation procedure, long reaction time and poor environmental friendliness in the prior art.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

An optical device for polishing metal surfaces

ActiveCN111375897BAvoid destructionAvoid contaminationLaser beam welding apparatusBirefringent crystalFemto second laser

In the optical device used for metal surface polishing provided by the present invention, the laser beam emitted by the femtosecond laser source is focused on the three-dimensional moving laser beam through the yttrium vanadate birefringent crystal, the attenuation plate and the focusing objective lens in sequence. The metal surface on the platform, and the metal surface is laser polished to obtain a smooth polished surface. The optical device for metal surface polishing provided by the present invention realizes the polishing of the metal surface by controlling the relevant femtosecond laser processing parameters. Polishing, compared with the existing mechanical polishing methods, it can achieve a large area of rapid polishing and micro-area polishing, without the need for auxiliary materials such as sandpaper, abrasive paste, chemical etchant; and the whole process is simple and easy to operate, and the thermal effect is negligible, can be Realize high-precision polishing; at the same time, due to the use of non-contact processing, it can effectively avoid stress damage and contamination on the surface of metal tungsten samples.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

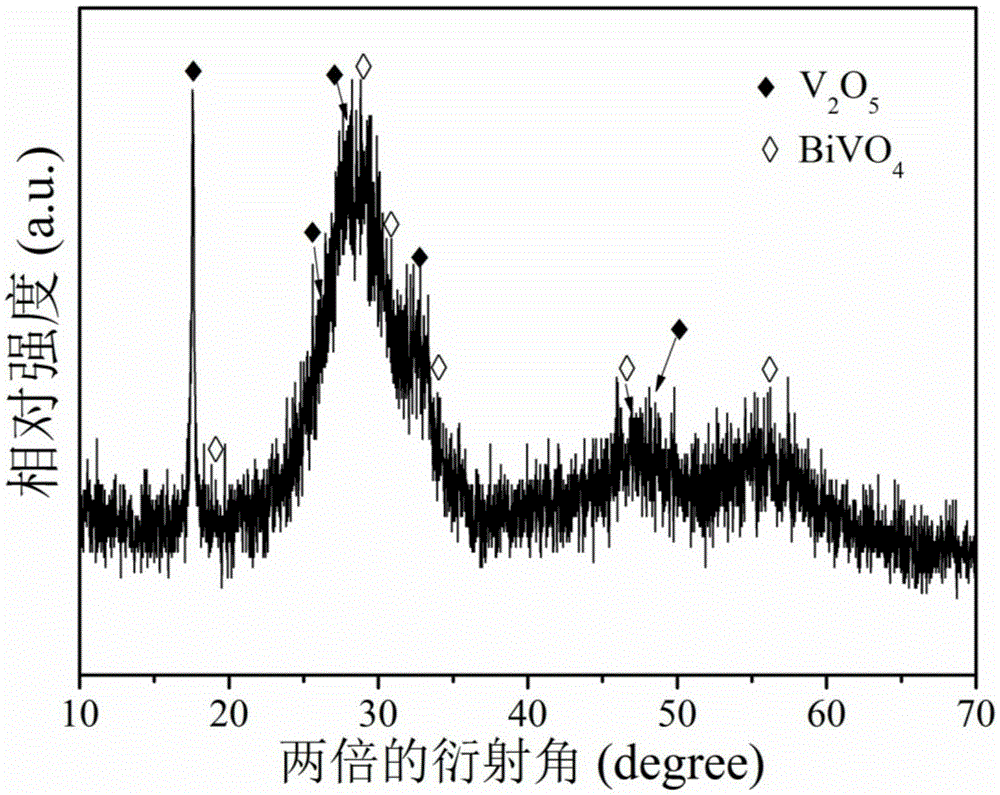

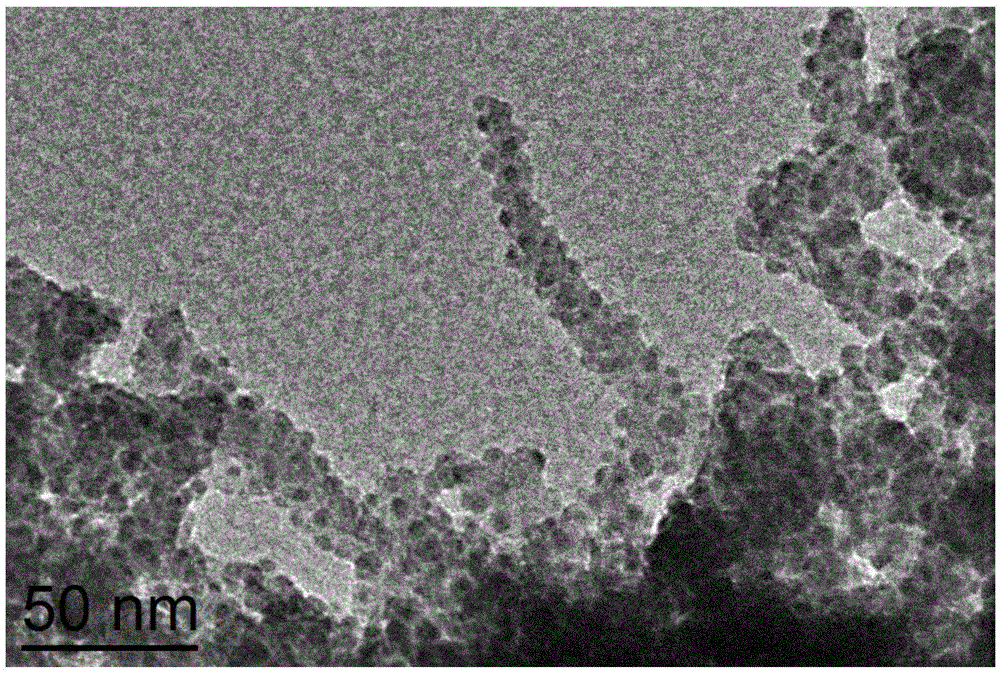

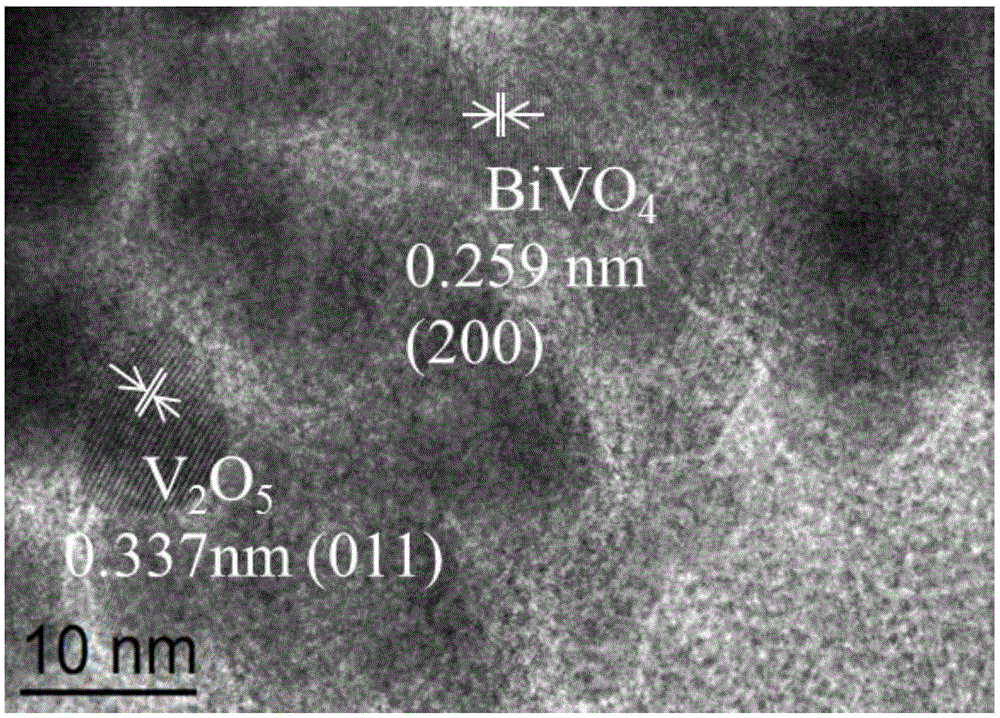

A preparation method of v2o5/bivo4 nanorod composite photocatalyst

InactiveCN103908960BStrong photoresponseHigh catalytic activityMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsVanadium oxideLight response

The invention discloses a preparation method of a V2O5 / BiVO4 (vanadium pentoxide / bismuth vanadium oxide) nanorod composite photocatalyst, anf belongs to the technical field of pollution control. The method comprises the steps of preparing a sodium oleate solution and a Na3VO4 (sodium orthovanadate) solution firstly, adding Bi(NO3)3.5H2O (bismuth nitrate pentahydrate) into the sodium oleate solution while stirring violently, then adding the Na3VO4 solution into a mixed solution of Bi(NO3)3 and sodium oleate, transferring into a reaction still for hydrothermal reaction, cooling a sample, extracting liquid supernatant with acetone, separating, washing the sample with cyclohexane and ethyl alcohol, separating, and drying under a vacuum condition, so as to obtain the V2O5 / BiVO4 nanorod composite photocatalyst. The V2O5 / BiVO4 composite semiconductor photocatalyst has the strong visible light response and the high catalytic activity and has the good application value and application prospect in the field of degradation of organic pollutants.

Owner:DALIAN UNIV OF TECH

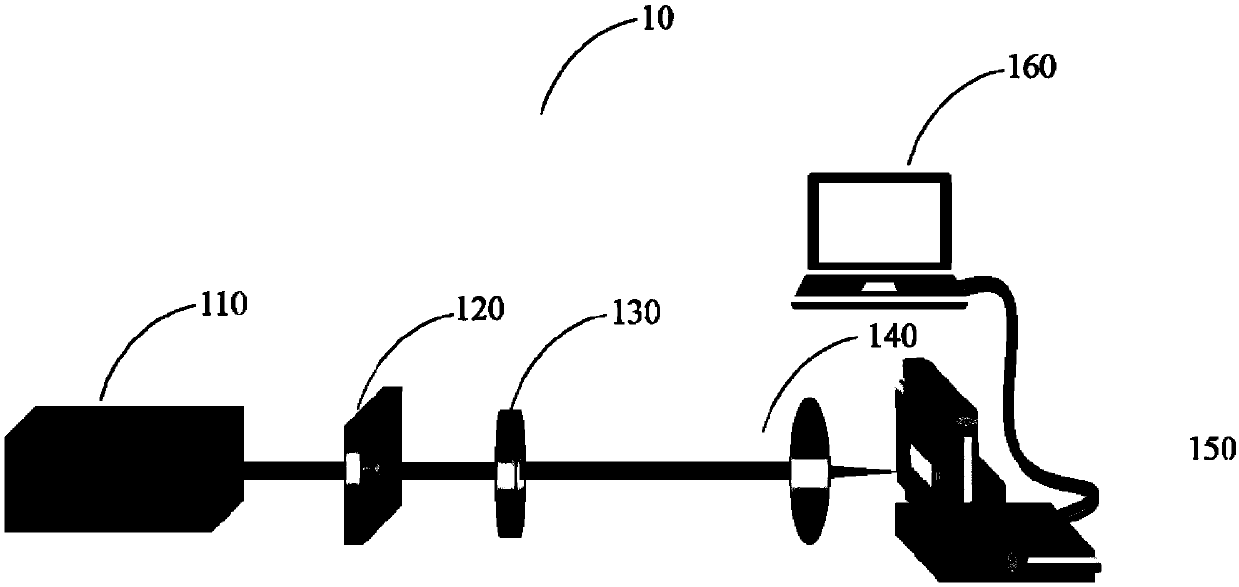

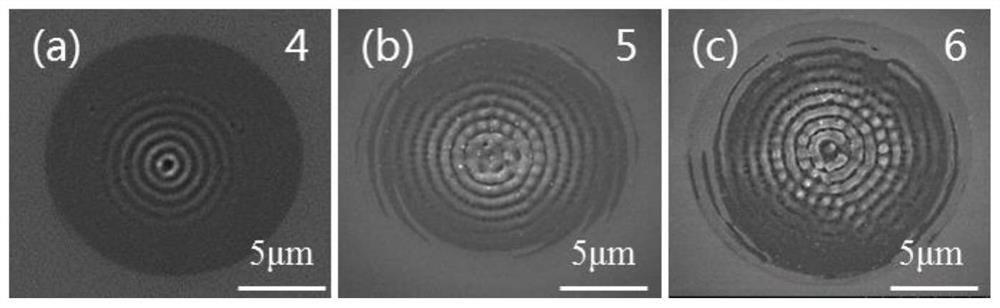

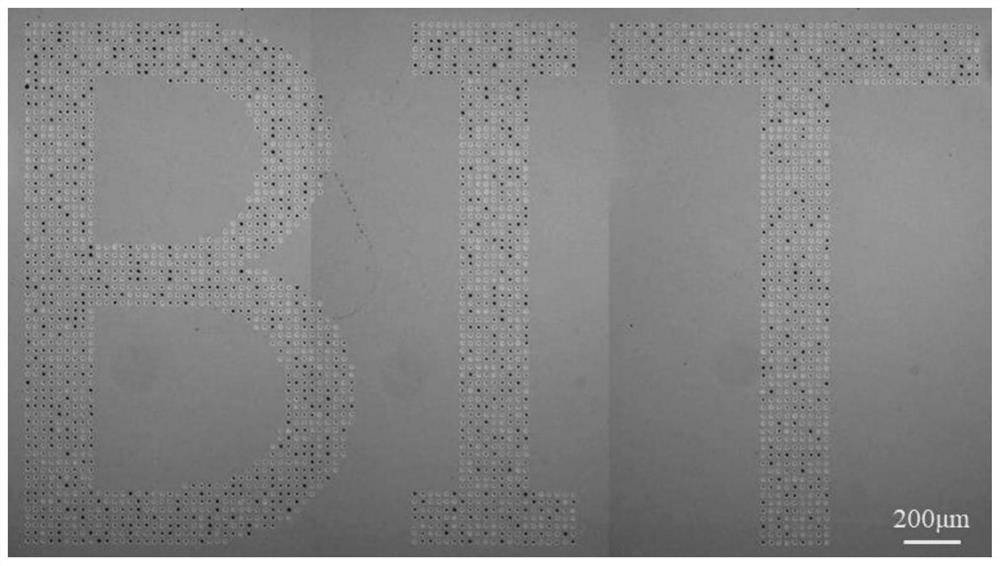

A method for preparing submicron concentric rings on silicon surface by femtosecond laser

ActiveCN112355483BSimple processLow costWelding/soldering/cutting articlesLaser beam welding apparatusFemto second laserPulse sequence

The invention relates to a method for preparing submicron concentric rings on a silicon surface with a femtosecond laser, belonging to the field of laser applications. In the present invention, a femtosecond laser single pulse is vertically incident through a yttrium vanadate crystal with a certain thickness to obtain a femtosecond laser double pulse sequence with a certain pulse delay whose polarization directions are perpendicular to each other and pulse energy is equal. The thickness of the yttrium vanadate crystal is The range of the femtosecond laser pulse should be satisfied, so that the delay range of the double pulse pulse generated after the femtosecond laser single pulse of the corresponding wavelength is about 0.5ps‑1.5ps; then use the attenuation sheet to adjust the total energy density of the femtosecond laser double pulse to the sample to be processed 1.6 to 2.2 times the ablation threshold of the material silicon; then this vertically polarized femtosecond laser double pulse is vertically focused on the surface of the material to be processed through a plano-convex lens; the number of pulse sequences focused on the surface of the material is controlled by the opening time of the optical switch For 4‑6 pieces, a single point of irradiation on the surface of the silicon material can prepare a submicron concentric ring structure on the silicon surface.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

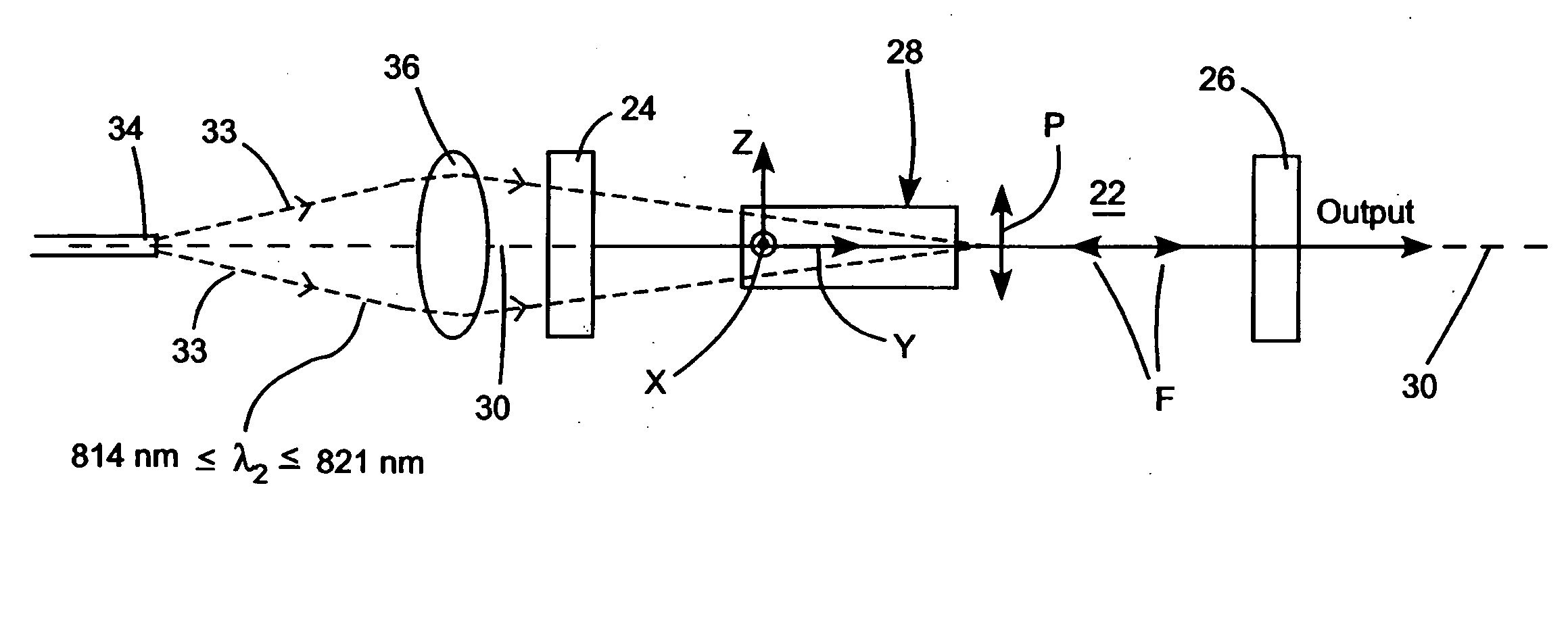

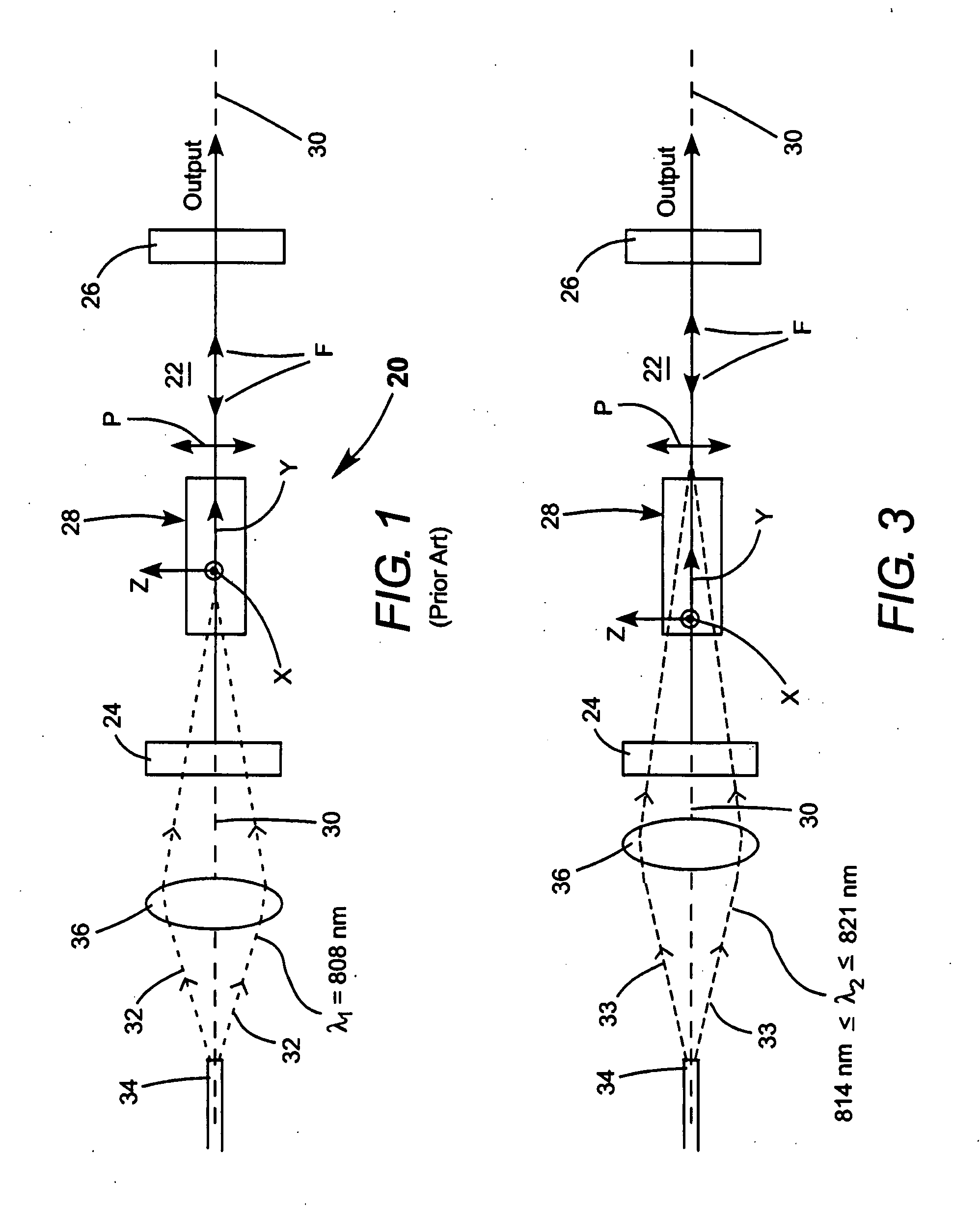

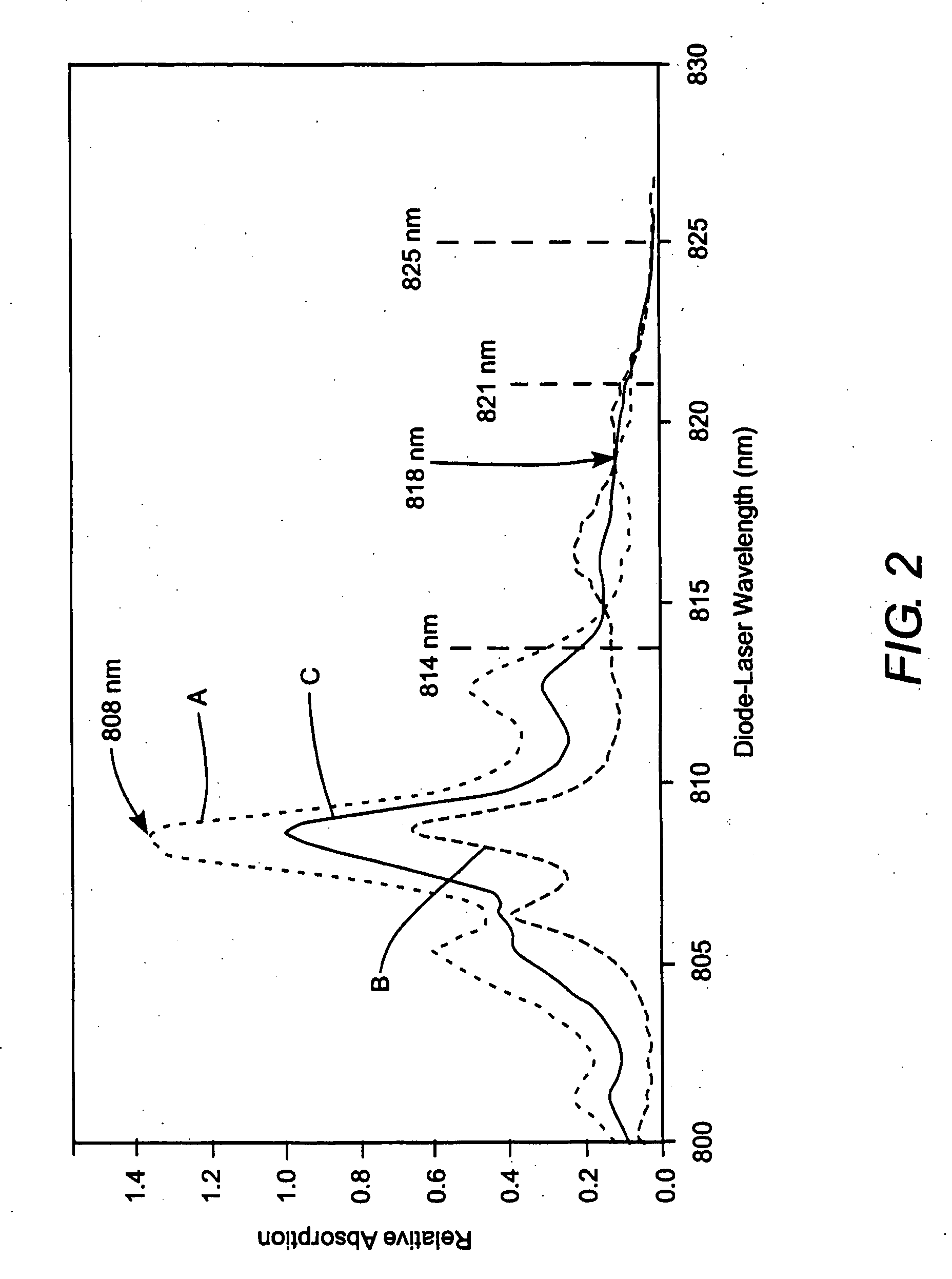

Off-peak optical pumping of yttrium orthovanadate

InactiveUS20050157771A1Excitation process/apparatusOptical resonator shape and constructionOptical pumpingLaser light

A laser includes an Nd:YVO4 crystal end-pumped with diode-laser light having a wavelength at which the absorption coefficient for Nd:YVO4 is less than about 0.35 (35%) of the absorption coefficient at 808 nm.

Owner:COHERENT INC

Microfluidic chip for capturing and/or counting cells as well as preparation method and application of microfluidic chip

ActiveCN112342115APowerful real-time monitoring capabilityGood up-conversion luminescence performanceBioreactor/fermenter combinationsBiological substance pretreatmentsPhotonic bandgapPhotonic crystal structure

The invention is applicable to the technical field of biological detection, and provides a microfluidic chip for capturing and / or counting cells as well as a preparation method and application of themicrofluidic chip. The microfluidic chip comprises a first base layer, an antibody-modified inverse opal photonic crystal structure, a second base layer and a microfluidic cavity, wherein the antibody-modified inverse opal photonic crystal structure is arranged on the first base layer and comprises an antibody modification layer and a yttrium vanadate inverse opal structure layer doped with Yb<3+>and Er<3+>; the second base layer is arranged on one side, close to the antibody-modified inverse opal photonic crystal structure, of the first base layer; and the microfluidic cavity is arranged between the first base layer and the second base layer. The photonic band gaps are controlled by regulating the size of the minimum repetitive units of photonic crystals, a double-layer Yb<3+> and Er<3+>doped yttrium vanadate inverse opal structure with different apertures and different band gaps is manufactured, up-conversion green light emission can be obviously enhanced through the band gap effect of the photonic crystals, and the problem of insufficient fluorescence intensity caused by low quantum efficiency in the existing up-conversion luminescence process is solved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com