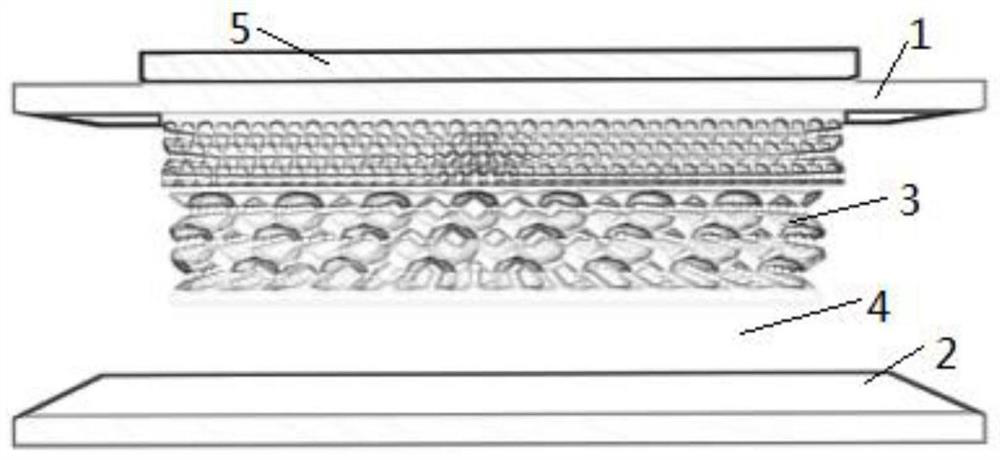

Microfluidic chip for capturing and/or counting cells as well as preparation method and application of microfluidic chip

A microfluidic chip, microfluidic cavity technology, applied in chemical instruments and methods, biochemical equipment and methods, enzymology/microbiology devices, etc., to achieve the effects of good biocompatibility, low price, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

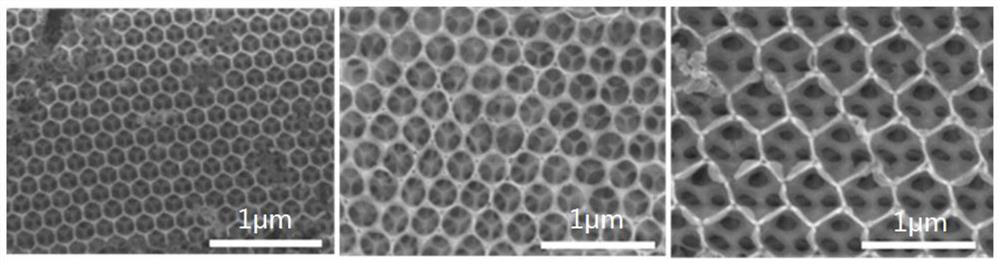

Embodiment 1

[0059] This embodiment provides a method for preparing a microfluidic chip, which includes the following steps:

[0060] S1. Preparation of polymethyl methacrylate (PMMA) solution:

[0061] (1) Prepare 15mg / mL NaOH solution for later use. Pour an appropriate amount of methyl methacrylate (MMA) into the cup, add the prepared NaOH solution, shake for 1.5min, the NaOH solution will wash away the polymerization inhibitor in the MMA, let it stand for stratification, and use a syringe to drain the lower layer of waste liquid Extract and discard. Repeat more than 4 times, do not take out the last time.

[0062] (2) Put a rotor of appropriate size into the three-necked flask, then put the above-mentioned cleaned MMA 6mL, water 80mL, and potassium persulfate 38mg into the three-necked flask, connect the condenser tube, and block the non-condensing port of the three-necked flask. Put all the above into an oil bath mixer, make the liquid level in the three-necked bottle lower than the...

Embodiment 2

[0078] This embodiment provides a method for preparing a microfluidic chip, which includes the following steps:

[0079] S1. Preparation of polymethyl methacrylate (PMMA) solution:

[0080] (1) Prepare 15mg / mL NaOH solution for later use. Pour an appropriate amount of methyl methacrylate (MMA) into the cup, add the prepared NaOH solution, shake for 1 min, the NaOH solution will wash away the polymerization inhibitor in the MMA, let it stand for stratification, and use a syringe to pump out the waste liquid in the lower layer mention discarded. Repeat more than 4 times, do not take out the last time.

[0081] (2) Put a rotor of appropriate size into the three-necked flask, then put the above-mentioned cleaned MMA 6mL, water 80mL, and potassium persulfate 35mg into the three-necked flask, connect the condenser tube, and block the non-condensing port of the three-necked flask. Put all the above into an oil bath mixer, make the liquid level in the three-necked bottle lower than...

Embodiment 3

[0091] This embodiment provides a method for preparing a microfluidic chip, which includes the following steps:

[0092] S1. Preparation of polymethyl methacrylate (PMMA) solution:

[0093] (1) Prepare 15mg / mL NaOH solution for later use. Pour an appropriate amount of methyl methacrylate (MMA) into the cup, add the prepared NaOH solution, shake for 2 minutes, the NaOH solution will wash away the polymerization inhibitor in the MMA, let it stand for stratification, and use a syringe to pump out the waste liquid in the lower layer mention discarded. Repeat more than 4 times, do not take out the last time.

[0094] (2) Put a rotor of appropriate size into the three-necked flask, then put the above-mentioned cleaned MMA 6mL, water 80mL, and potassium persulfate 40mg into the three-necked flask, connect the condenser tube, and block the non-condensing port of the three-necked flask. Put all the above into an oil bath mixer, make the liquid level in the three-necked bottle lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com