Vanadate for measuring dislocation density and etching process of doped monocrystal

A technique for density determination, vanadate, used in single crystal growth, single crystal growth, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

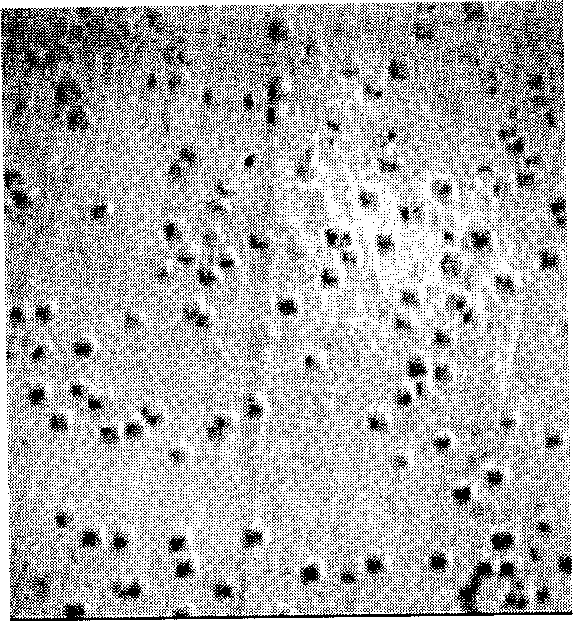

[0014] Example 1: The polished Nd:GdVO 4 Put the crystal into the etching solution. The composition of the etching solution is 20ml of concentrated phosphoric acid + 1ml of hydrofluoric acid. Etch at 160°C for 6 minutes. Rinse the etched crystal in clean water, dry it with alcohol cotton, and then examine it under a polarizing microscope. Under the observation, square cone-shaped corrosion pits can be seen on the (001) plane, and the field of view area is calculated with a micrometer, and the dislocation density is calculated. See figure 1 .

example 2

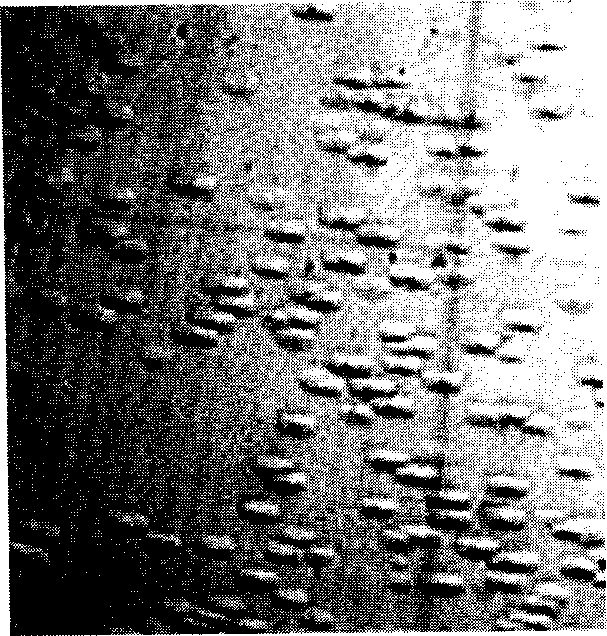

[0015] Example 2: The polished Nd: YVO 4 Put the crystal into the etching solution. The composition of the etching solution is 20ml concentrated phosphoric acid + 1.5ml hydrofluoric acid. Etch at 170°C for 6 minutes. Rinse the etched crystal in clean water and dry it with alcohol cotton, and then examine it under a polarizing microscope. Under the observation, the rectangular cone-shaped corrosion pit can be seen on the (100) plane, and the field of view area is calculated with a micrometer, and the dislocation density is calculated. See figure 2 .

example 3

[0016] Example 3: The polished Nd: YVO 4 Put the crystal into the etching solution, the composition of which is 20ml concentrated phosphoric acid + 2ml hydrofluoric acid, etch at 170°C for 7 minutes, rinse the etched crystal in clean water, dry it with alcohol cotton, and then examine it under a polarizing microscope Observation shows that rectangular conical corrosion pits can be seen on the (100) plane, and the field of view area is calculated with a micrometer, and the dislocation density is calculated. See image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com