Polarized prism made of yttrium vonadate crystal

A polarizing prism and yttrium vanadate technology, applied in prisms, polarizing elements, etc., can solve the problems of difficult to obtain crystals, low crystal utilization rate, high price, etc., and achieve the effect of simple bonding and fixing and detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Now enumerate typical embodiment of the present invention:

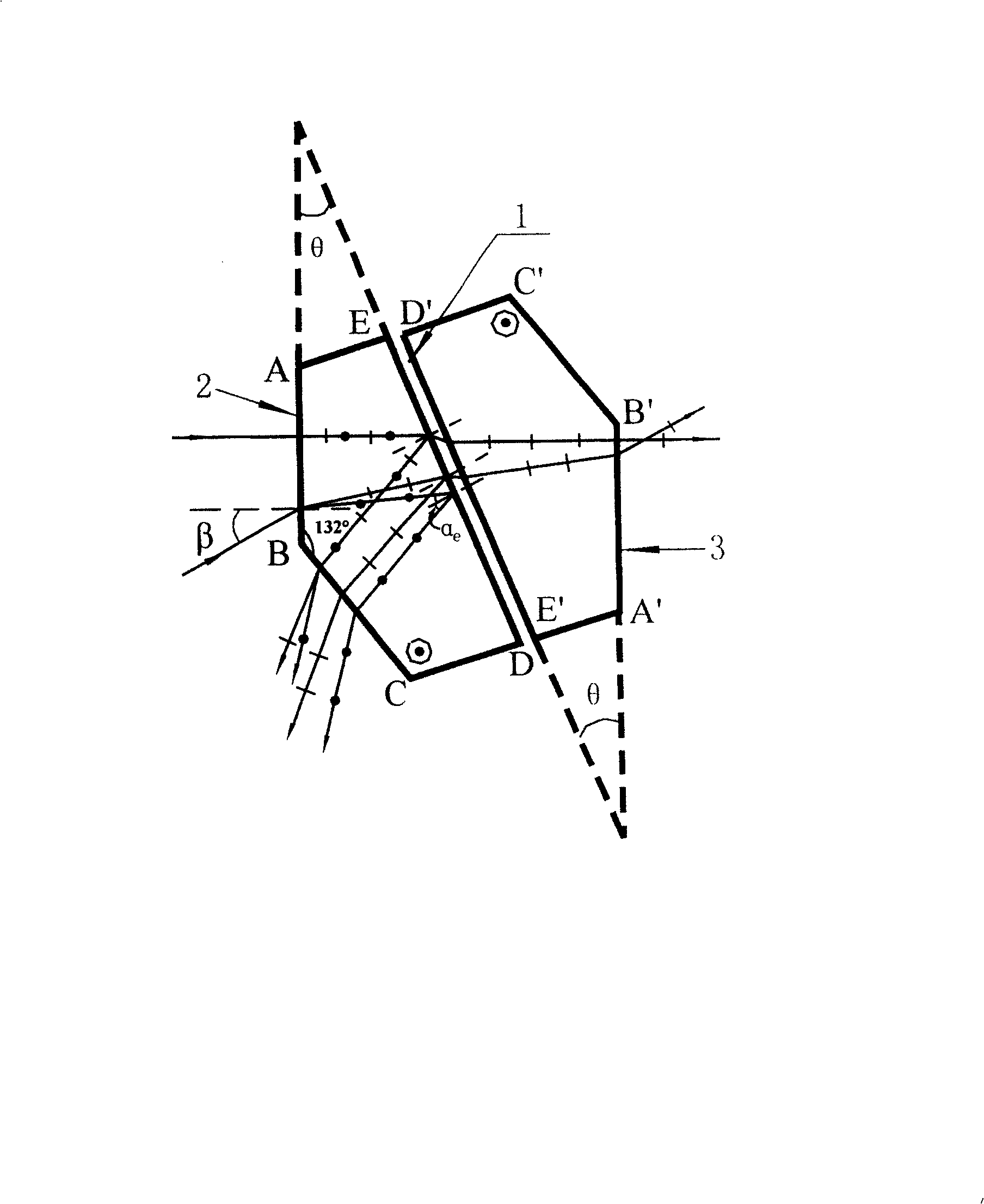

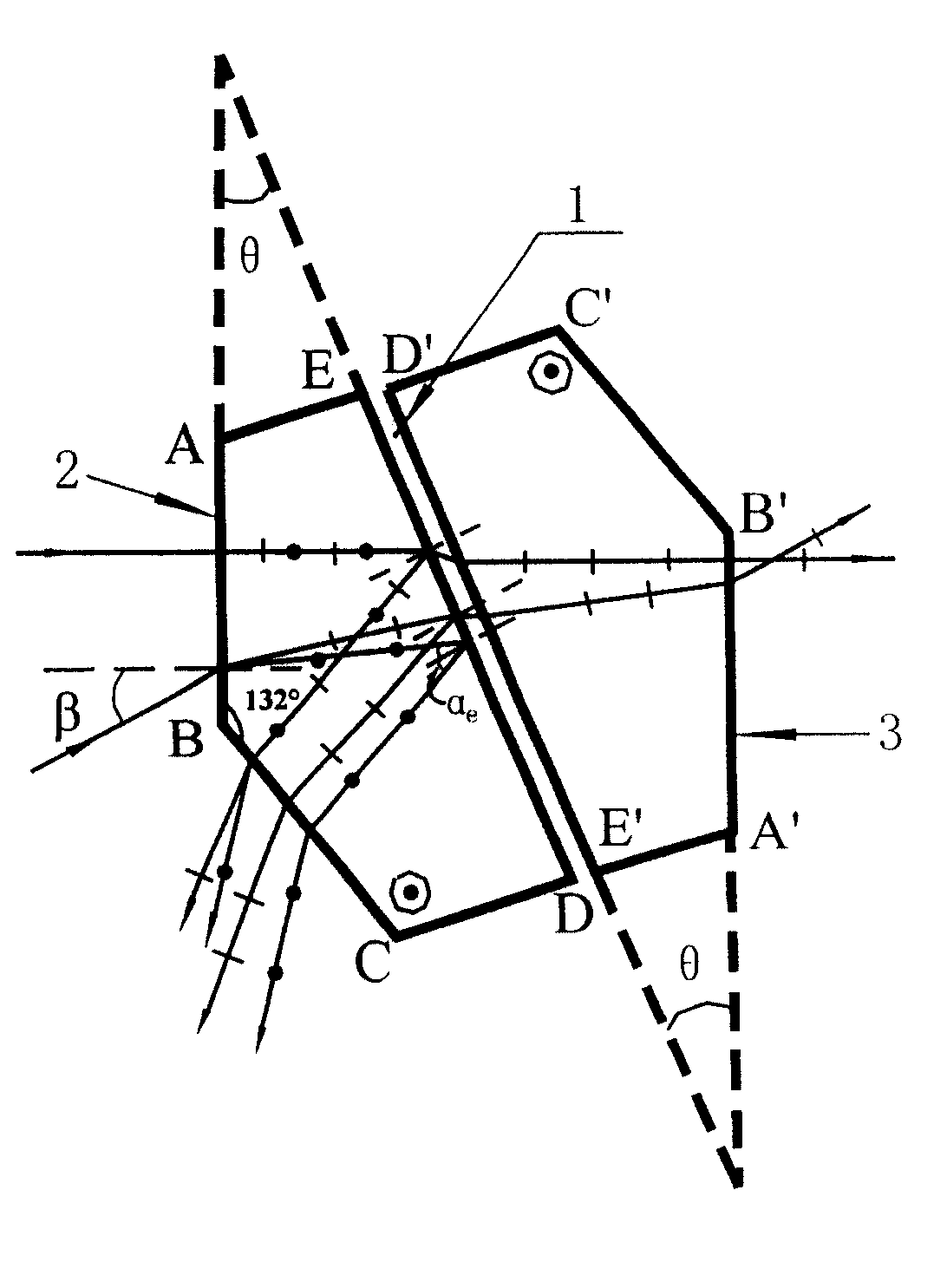

[0013] YVO that can be pulled along the optical axis and has a large enough diameter 4 The crystal is cut perpendicular to the optical axis, and its diameter and cutting thickness depend on the needs of the user; it is cut into two symmetrical halves first, so that each half has five faces AB, BC, CD, DE, EA, and has the angle and Shape, the three larger surfaces AB, BC and DE are processed and polished. Then, the processed two prisms are bonded and fixed according to the above-mentioned requirements of leaving an air gap and jumping angle. The incident surface AB and the exit surface A'B' are coated with an anti-reflection film using a wavelength to improve the transmittance of the prism; finally, the polarizing prism is installed in a rotatable and two-dimensionally adjustable adjustment frame.

[0014] A layer of air gap should be reserved between the two polished surfaces of DE and E'D' of the two prisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com