Optical waveguide devices

一种器件、脊部的技术,应用在光波导器件领域,能够解决传播损失变大、难加工台横向移动等问题,达到抑制传播损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

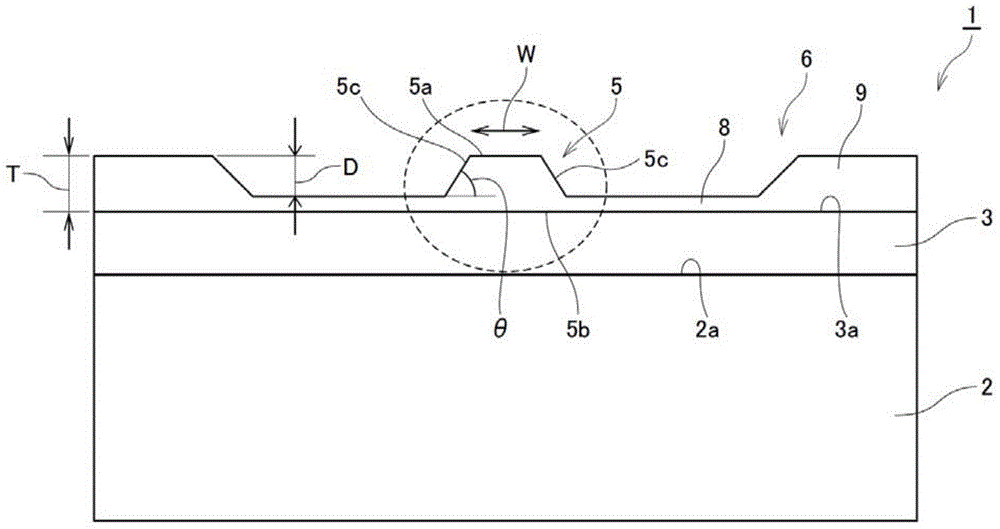

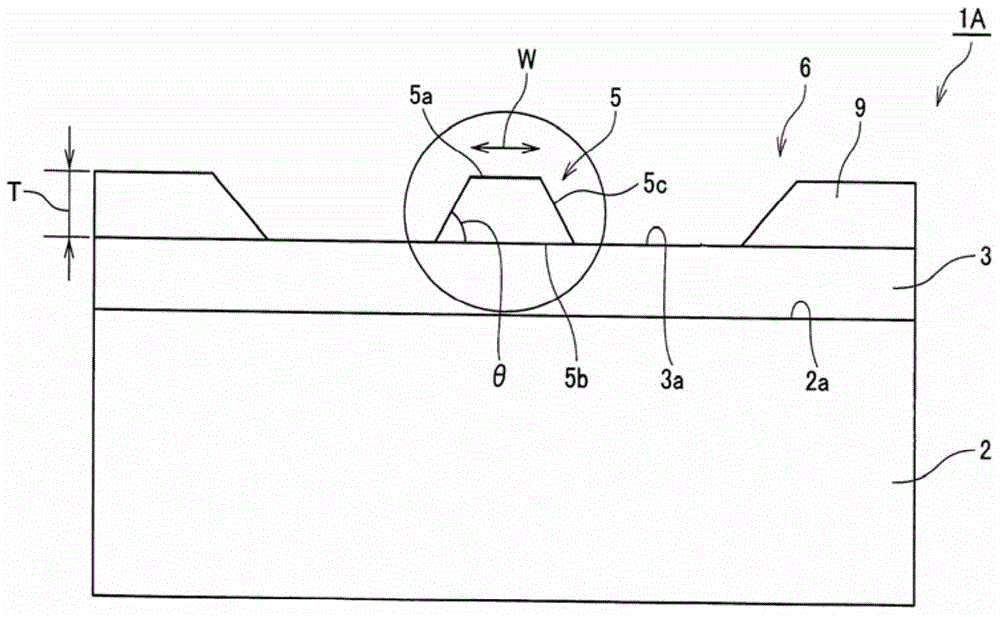

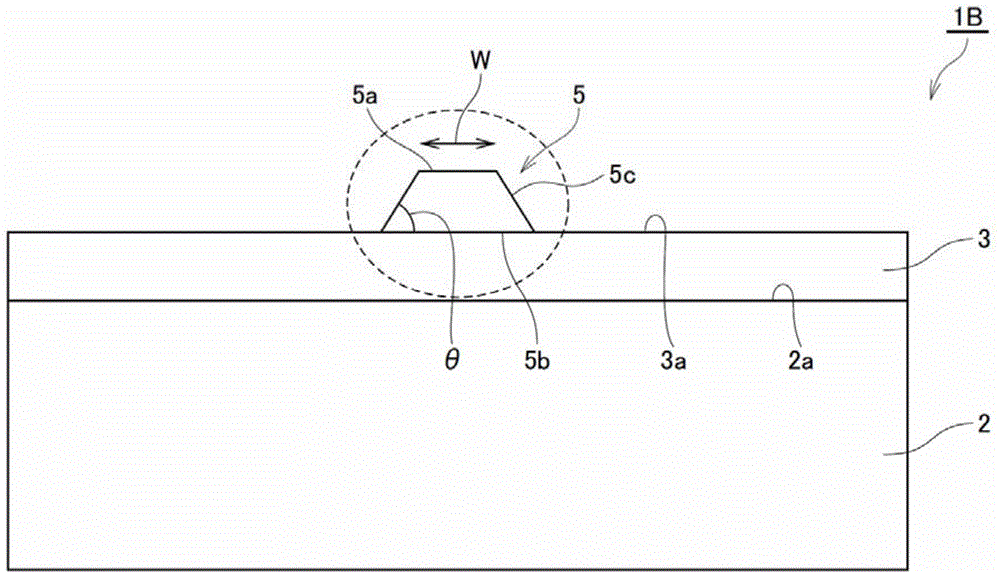

[0078] make figure 1 , Figure 4 (a) and Figure 5 Documented device 1.

[0079] Specifically, a dielectric layer 3 (thickness 2.0 μm) / SiO made of lithium niobate doped with MgO 2 A laminated body of the support substrate 2 with a thickness of .5 mm consisting of the clad layer / adhesive layer / Y plate not doped with lithium niobate. On this dielectric layer 3, Ta 2 o 5 membrane.

[0080] Next, a molybdenum film having a thickness of 100 nm was formed on the upper surface 3 a of the dielectric layer 3 and the bottom surface of the support substrate 2 . Next, a resist pattern is formed on the dielectric layer and the molybdenum film by photolithography (resist coating and development). In addition, a resist is applied to the entire bottom surface of the support substrate 2 . Next, the molybdenum film was wet-etched to remove the resist, and a pattern made of the molybdenum film was formed.

[0081] Next, the laminated body was dipped in 50% HF whose temperature was adjus...

Embodiment 2

[0098] A device was produced in the same manner as in Example 1. However, the material of the dielectric layer 3 is a lithium tantalate single crystal doped with MgO. As a result, the same result as in Example 1 was obtained. In addition, as a result of the tape test, it was confirmed that no film was attached to the tape and no ridges were peeled off from the device.

Embodiment 3

[0100] A device was produced in the same manner as in Example 1. However, the material of the dielectric layer 3 is yttrium vanadate crystal. In order to confirm the performance of the optical waveguide, the propagation loss at a wavelength of 980 nm was measured in the same manner as in Example 1, and the result was 0.5 dB / cm. In addition, as a result of the tape test, it was confirmed that no film was attached to the tape and no ridges were peeled off from the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com