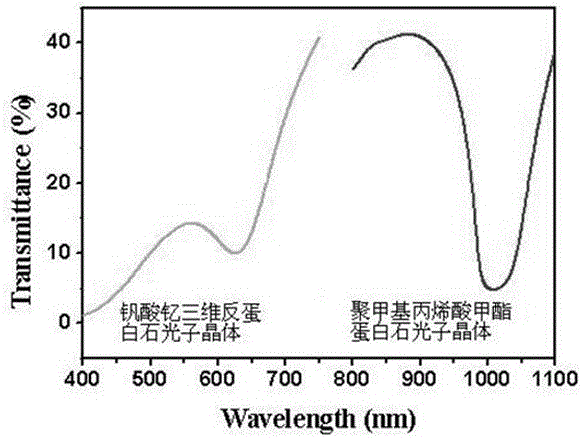

Preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal

A photonic crystal and inverse opal technology, applied in crystal growth, chemical instruments and methods, optics, etc., can solve the problem that the photonic band gap is difficult to precisely control, the photonic crystal cannot meet the low-cost precise control of the photonic band gap, mass production, and preparation costs Advanced problems, to achieve the effect of low preparation cost, precise photonic band gap, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal, comprising the steps of:

[0029] (1) Preparation of polymethyl methacrylate nanospheres

[0030] Add 200 ml of water, 12 ml of methyl methacrylate, and 90 mg of potassium persulfate into a three-hole round bottom bottle, react in an oil bath at 90°C for 90 minutes, and then close the oil bath. This is polymethyl methacrylate nano spherical emulsion.

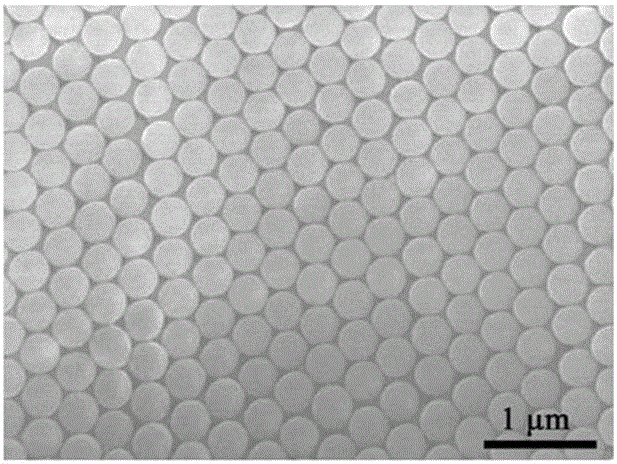

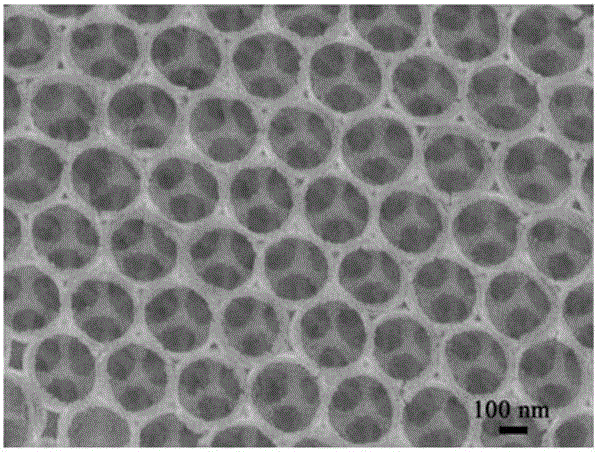

[0031] (2) Growth of Opal Structured Photonic Crystal Template

[0032] Add 60ml of water and 1ml of polymethyl methacrylate nano-emulsion to the beaker, take a clean glass slide and insert it vertically into the beaker. The beaker was placed in a blast drying oven at 30°C, and under the action of capillary force, a polymethyl methacrylate opal photonic crystal template was prepared.

[0033] (3) Preparation of inverse opal photonic crystal precursor solution

[0034] Dissolve 1149 mg of yttrium nitrate and 351 mg of ammonium met...

Embodiment 2

[0039] A preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal, comprising the steps of:

[0040] (1) Preparation of polymethyl methacrylate nanospheres

[0041] Add 200 ml of water, 11 ml of methyl methacrylate, and 77 mg of potassium persulfate into a three-hole round bottom bottle, react in an oil bath at 90°C for 90 minutes, and then close the oil bath. This is polymethyl methacrylate nano spherical emulsion.

[0042] (2) Growth of Opal Structured Photonic Crystal Template

[0043] Add 55ml of water and 1ml of polymethyl methacrylate nano-emulsion into the beaker, take a clean glass slide and insert it vertically into the beaker. The beaker was placed in a blast drying oven at 30°C, and under the action of capillary force, a polymethyl methacrylate opal photonic crystal template was prepared.

[0044] (3) Preparation of inverse opal photonic crystal precursor solution

[0045] Dissolve 1120 mg of yttrium nitrate and 340 mg of ammonium m...

Embodiment 3

[0049] A preparation method of yttrium vanadate three-dimensional inverse opal photonic crystal, comprising the steps of:

[0050] (1) Preparation of polymethyl methacrylate nanospheres

[0051] Add 200 ml of water, 13 ml of methyl methacrylate, and 104 mg of potassium persulfate into a three-hole round bottom bottle, react in an oil bath at 90°C for 90 minutes, then close the oil bath, and this is polymethyl methacrylate nanospheres Emulsion.

[0052] (2) Growth of Opal Structured Photonic Crystal Template

[0053] Add 65ml of water and 1ml of polymethyl methacrylate nano-emulsion to the beaker, and insert a clean glass slide into the beaker vertically. The beaker was placed in a blast drying oven at 30°C, and under the action of capillary force, a polymethyl methacrylate opal photonic crystal template was prepared.

[0054] (3) Preparation of inverse opal photonic crystal precursor solution

[0055] Dissolve 1120 mg of yttrium nitrate and 340 mg of ammonium metavanadate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com