Raw material synthesis method for growing yttrium vanadate crystal through pulling method

A synthesis method and technology of yttrium vanadate, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as stripes, blackened crystals, and easy cracking of yttrium vanadate crystals, and achieve low energy consumption and low cost. Low, the effect of low production equipment configuration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (liquid phase synthesis of yttrium orthovanadate):

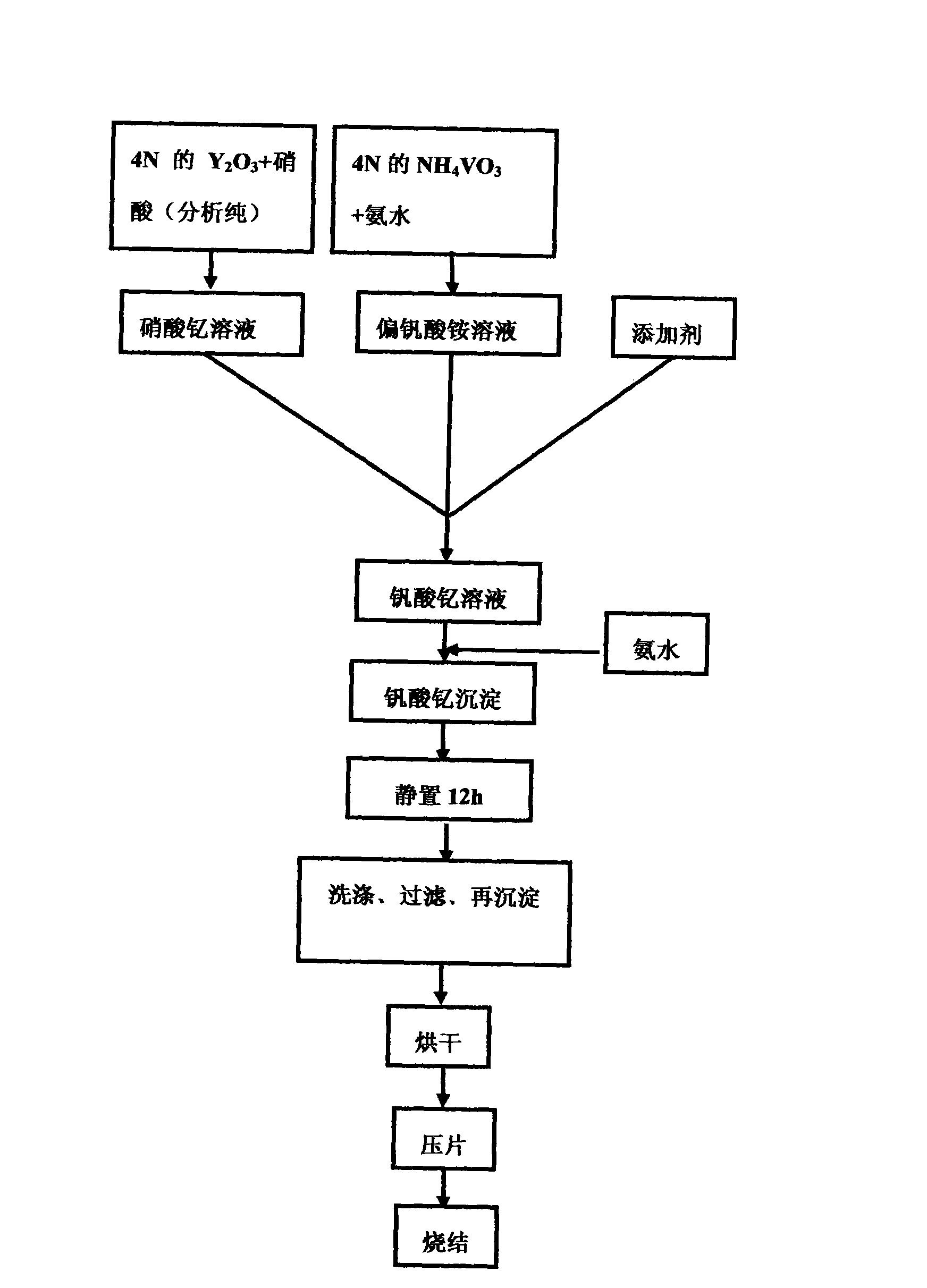

[0046] Y with a purity of 99.99% 2 o 3 Dissolved in concentrated nitric acid to give Y(NO 3 ) 3 solution. Will NH 4 VO 3 (4N) dissolved in ammonia solution to obtain NH 4 VO 3 solution. According to attached figure 1 The method of the synthetic route puts Y(NO 3 ) 3 solution to NH 4 VO 3 Slowly drop into the solution (the molar ratio is 1.02: 1), and the nitrate mixed solution of the additive (additive La 2 o 3 , BaO and CaO account for the product YVO 4 The weight percentages are 0-0.5%, 0-0.1% and 0-0.1%), ammonia water is dropped into the mixed solution, and stirred for a long time so that the pH value is controlled at about 7.2. The above precipitate was aged and suction filtered to obtain a white precipitate, which was taken out and dried, then pressed into tablets, and finally put into a muffle furnace for sintering at 1100°C for 10 hours, and the product was white. Put the white bl...

Embodiment 2

[0047] Embodiment 2 (the liquid phase synthesis of Nd-doped yttrium vanadate):

[0048] Y with a purity of 99.99% 2 o 3 and Nd 2 o 3 (Nd doping concentration is 0.5 mol%) The mixed powder is dissolved in concentrated nitric acid to obtain a nitrate solution. Will NH 4 VO 3 (4N) dissolved in ammonia solution to obtain NH 4 VO 3 solution. According to attached figure 1 The method of the synthetic route converts the mixed solution of nitrate to NH 4 VO 3 ((Y+Nd) and V molar ratio is 1.02: 1) in the solution slowly, drop simultaneously also the nitrate mixed solution of additive (additive La 2 o 3 , BaO and CaO account for the product YVO 4 The weight percentages are 0-0.5%, 0-0.1% and 0-0.1%), ammonia water is dropped into the mixed solution, and stirred for a long time so that the pH value is controlled at 7.2. The above-mentioned precipitate was aged and pumped, and finally a white pure white precipitate was obtained, which was taken out and dried, then pressed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com