A method for preparing submicron concentric rings on silicon surface by femtosecond laser

A femtosecond laser, concentric ring technology, applied in the field of laser applications, to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

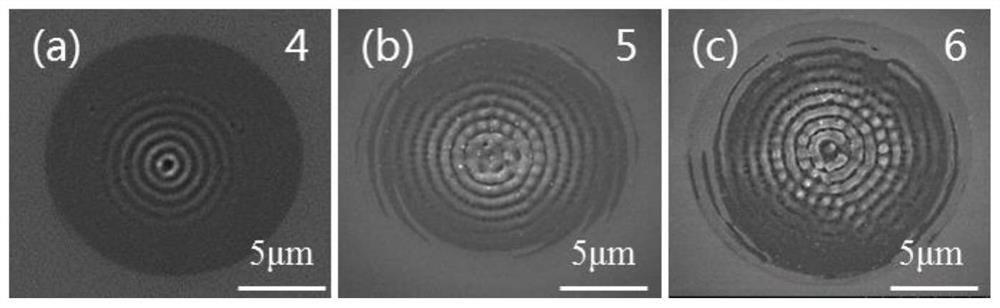

Examples

Embodiment 1

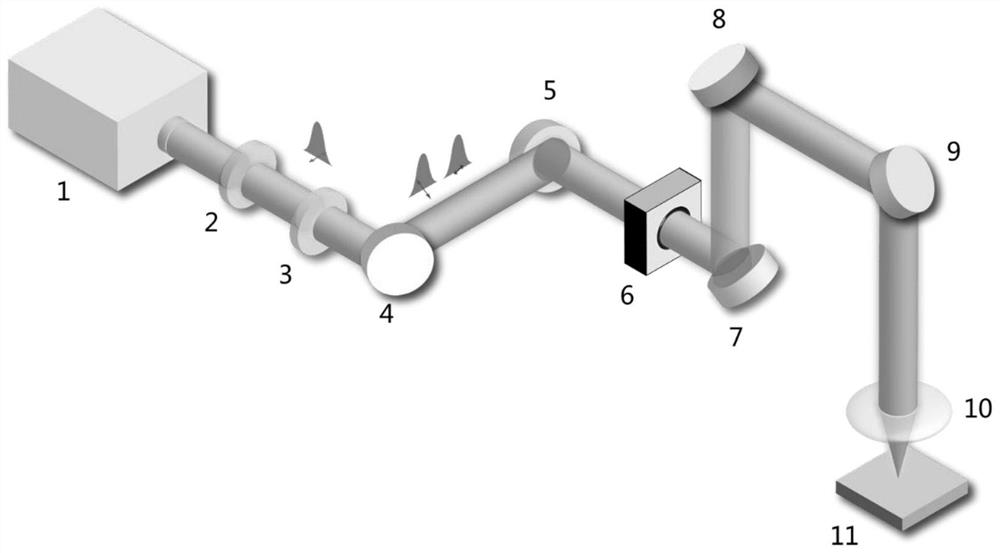

[0022] A method for preparing submicron concentric rings on a silicon surface with a femtosecond laser, the specific steps are as follows:

[0023] Step (1) Use femtosecond laser 1 to generate 800nm horizontally polarized femtosecond laser single pulse, and adjust the focused laser energy density to about twice (1.6 times to 2.2 times range), about 1.0J / cm 2 ;

[0024] Step (2) is that the yttrium vanadate crystal 3 of 1.2mm is penetrated by the femtosecond laser single pulse perpendicular incidence in the step (1), and the yttrium vanadate crystal 3 is rotated so that its optical axis is in line with that of the step (1). The angle between the polarization direction of the femtosecond laser single pulse is 45°, and the femtosecond laser double pulse sequence with the polarization directions perpendicular to each other, the pulse energy equal, and the pulse delay about 0.85ps is obtained;

[0025] Step (3) Modify the repetition frequency of the femtosecond laser 1 to 10 Hz...

Embodiment 2

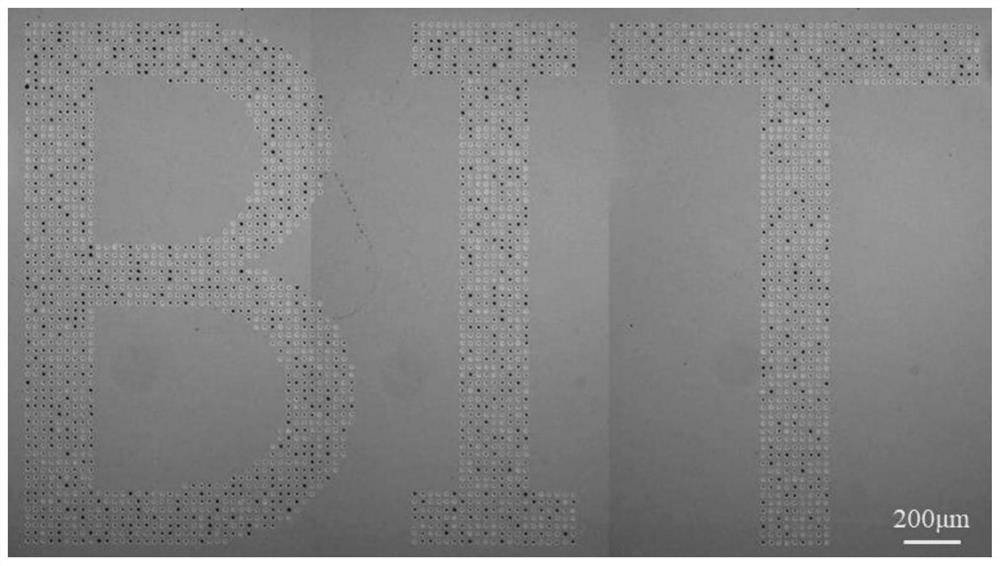

[0030] By adopting the method of the present invention, a large-area submicron concentric ring array is prepared on the silicon surface, and applied to the display of structural color.

[0031] The processing equipment and femtosecond laser processing parameters are the same as in Example 1. A large-area submicron concentric ring array in the shape of "BIT" is processed on the surface of the silicon wafer, and the area size is 3.7mm*2mm. Such as image 3 Shown is an optical microscope image of the processed area. Since the concentric ring structure has diffraction gratings in all directions, when white light is used to irradiate the processing area vertically, such as Figure 4 In the method shown, the structural color can be observed in all directions by rotating the sample where the processing area is located. The advantage of the present invention is that, compared with the traditional parallel linear grating structure, the structural color can only be observed in one di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com