Preparation method of rare-earth yttrium vanadate

A technology of rare earth yttrium vanadate and yttrium vanadate, which is applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of cumbersome preparation process, long reaction time, and insufficient environmental protection, and achieve simple preparation process and raw material composition The effect of less points and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of rare earth yttrium vanadate, using yttrium nitrate, sodium nitrate and sodium orthovanadate as raw materials, comprises the following steps:

[0034] 1) Prepare mixed suspension: use deionized water and NaNO 3 Prepare 18mL of mixed suspension of yttrium nitrate and sodium orthovanadate, wherein Y 3+ / VO 4 3- The molar concentration ratio is 1:1, NaNO 3 Concentration 1%;

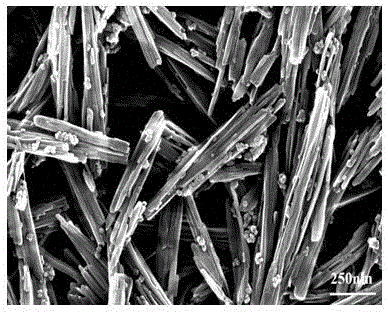

[0035] 2) Hydrothermal reaction: transfer the mixed suspension into a closed container, seal it and place it in an oven at 180°C for 24 hours of reaction, and collect the solid as bundle-shaped yttrium vanadate. The obtained product was washed with deionized water and absolute ethanol, dried at 80°C for 6 hours, and tested for characterization. figure 1 (a) is the XRD pattern of obtained product, proves that obtained product is YVO 4 ; figure 2 It is the field emission scanning electron micrograph of the product, which shows that the product has a beam-like structure....

Embodiment 1

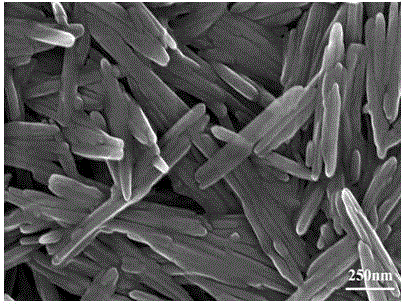

[0045] The preparation method of the rare earth yttrium vanadate of the present embodiment, the yttrium vanadate is in a beam structure, and the beam structure is prepared through the following steps:

[0046] 1) Prepare mixed suspension: use deionized water and NaNO 3 Prepare the mixed suspension of yttrium nitrate and sodium orthovanadate, wherein: Y 3+ Ions and VO 4 3- Ionic - The molar concentration ratio is 1.05:1; NaNO3 The concentration is 1%.

[0047] 2) Hydrothermal reaction: transfer the mixed suspension into a closed container, seal it and put it in an oven at 150°C for 8 hours to react, then collect the solid as bundle-shaped yttrium vanadate.

[0048] The specific preparation steps of the mixed suspension are as follows:

[0049] a) Use a mixture of deionized water and surfactant to prepare a mixed solution of yttrium nitrate and record it as liquid A;

[0050] b), and then use deionized water to prepare sodium orthovanadate solution and record it as B solut...

Embodiment 2

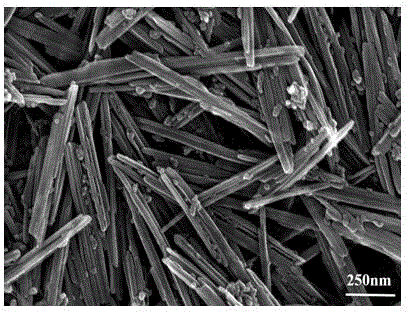

[0054] The preparation method of the rare earth yttrium vanadate of the present embodiment, the yttrium vanadate is in a beam structure, and the beam structure is prepared through the following steps:

[0055] 1) Prepare mixed suspension: use deionized water and NaNO 3 Prepare the mixed suspension of yttrium nitrate and sodium orthovanadate, wherein:

[0056] Y 3+ Ions and VO 4 3- Ionic - The molar concentration ratio is 1:1; NaNO 3 The concentration is 2%.

[0057] 2) Hydrothermal reaction: transfer the mixed suspension into a closed container, seal it and put it in an oven at 180°C for 12 hours of reaction, then collect the solid as bundle-shaped yttrium vanadate.

[0058] The specific preparation steps of the mixed suspension are as follows:

[0059] a), with deionized water and NaNO 3 The mixed solution of the mixture preparation yttrium nitrate is recorded as A liquid;

[0060] b), and then use deionized water to prepare sodium orthovanadate solution and record i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com