UV adhesive curing method and OLED packing method

A technology of encapsulation method and curing method, which is applied in the direction of electrical solid devices, devices for coating liquid on the surface, semiconductor/solid device manufacturing, etc., which can solve the problems of OLED organic material degradation, affecting OLED organic materials, and glass substrate temperature rise, etc. , to reduce the temperature, avoid the deterioration of the organic functional layer, and improve the service life and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

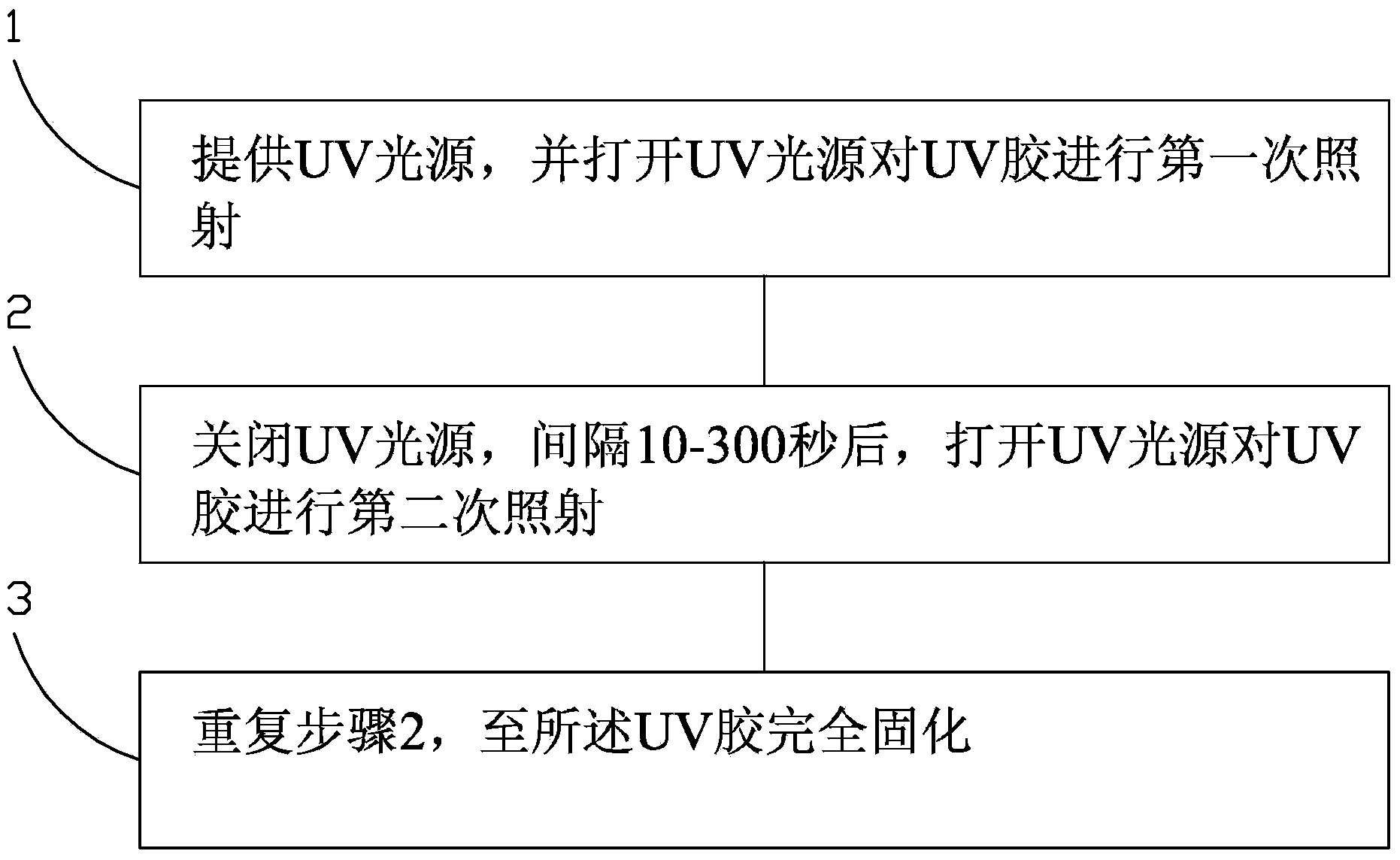

[0041] see image 3 and Figure 4 , the invention provides a UV glue curing method, comprising the following steps:

[0042] Step 1. Provide a UV light source 60 and turn on the UV light source 60 to irradiate the UV glue 24 for the first time.

[0043] Specifically, a UV light source 60 is provided, and the illuminance of the UV light source 60 is 100mw / cm 2 , turn on the UV light source 60, and irradiate the UV glue 24 for the first time, and the time of the first irradiating time is 60 seconds.

[0044] Step 2: Turn off the UV light source 60, and turn on the UV light source 60 to irradiate the UV glue 24 for the second time after an interval of 10-300 seconds.

[0045] Specifically, the UV light source 60 is turned off, and after an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com