Segmented lifting and conveying device of deep-sea mining annular pipelines

A circular pipeline and deep-sea mining technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of blocked conveying pipelines, low conveying efficiency, poor practicability, etc., to avoid distortion, improve conveying efficiency, and use Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the drawings.

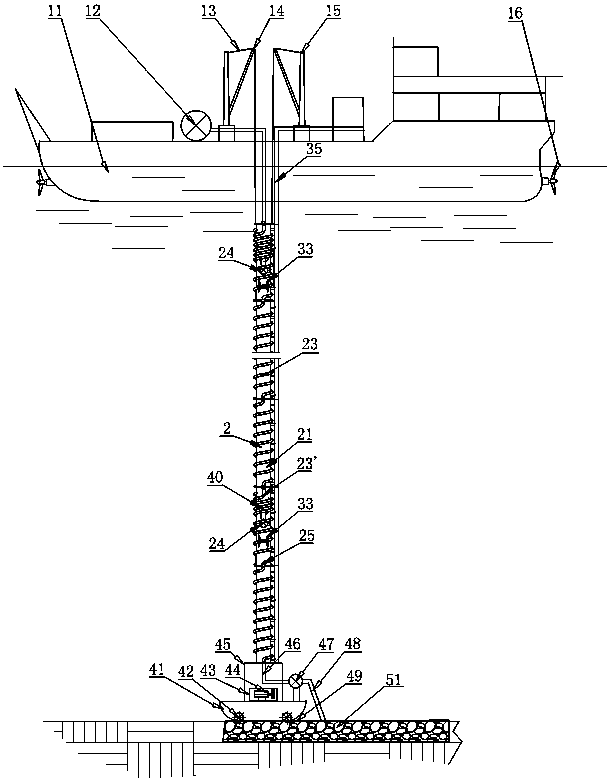

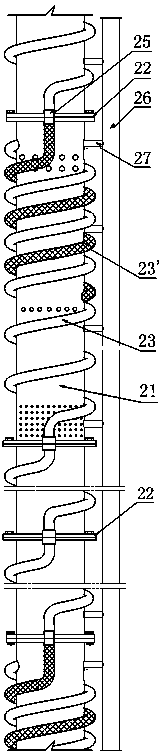

[0015] The length of the total support pipe 2 is based on the design requirements and site construction requirements. The distance between 100 and 1000 meters is a segment of support pipe. The total support pipe is made up of two or more segments of multi-segment support pipe 21, fixedly connected by connecting piece support pipe flange 22 Whole, such as figure 1 , figure 2 Shown.

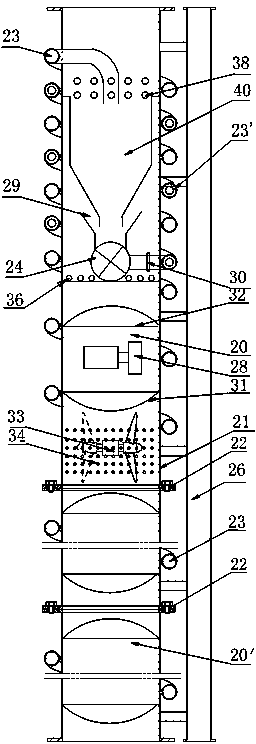

[0016] The buoyancy air cabins 20, 20' are composed of upper and lower semicircular cover plates 31, baffles 32 and part of the inner wall of the support tube 21. The only difference is the length. The length of the buoyancy air cabin 20 and the buoyancy air cabin 20 can be reduced. The weight of the entire device increases buoyancy, such as image 3 Shown.

[0017] In each section of the support pipe 21 constituting the main support pipe, there are installed two or more buoyancy air cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com