Production apparatus for nitromethane

A technology for nitromethane and equipment, applied in the field of equipment for producing nitromethane, can solve the problems that restrict the large-scale and scientific development of the industry, the production line cannot be fully automated, and the continuous production cannot be continuously operated, etc. The effect of eliminating leaks and leaks and improving the level of on-site management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technology, features, purposes and effects of the present invention easier to understand and understand, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention, but the present invention is not limited thereto.

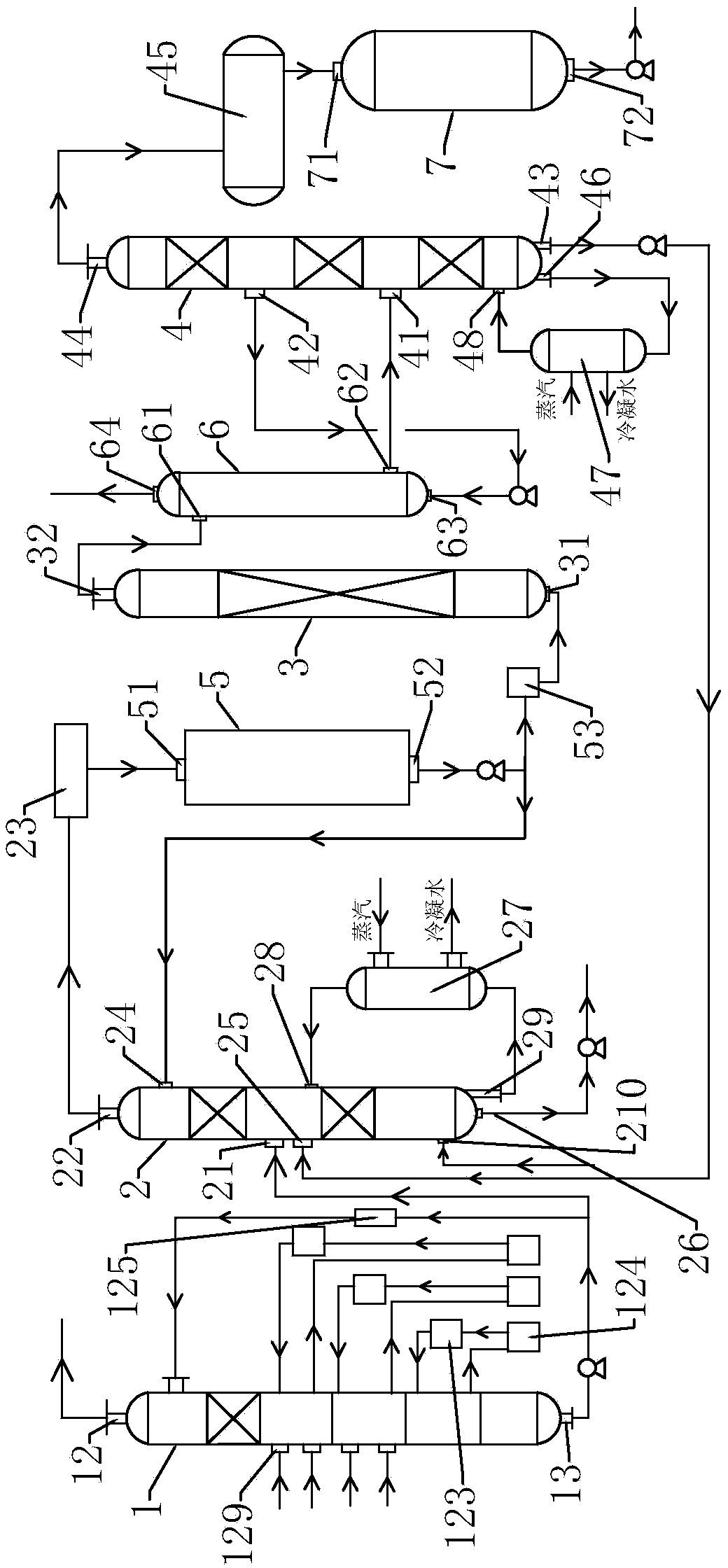

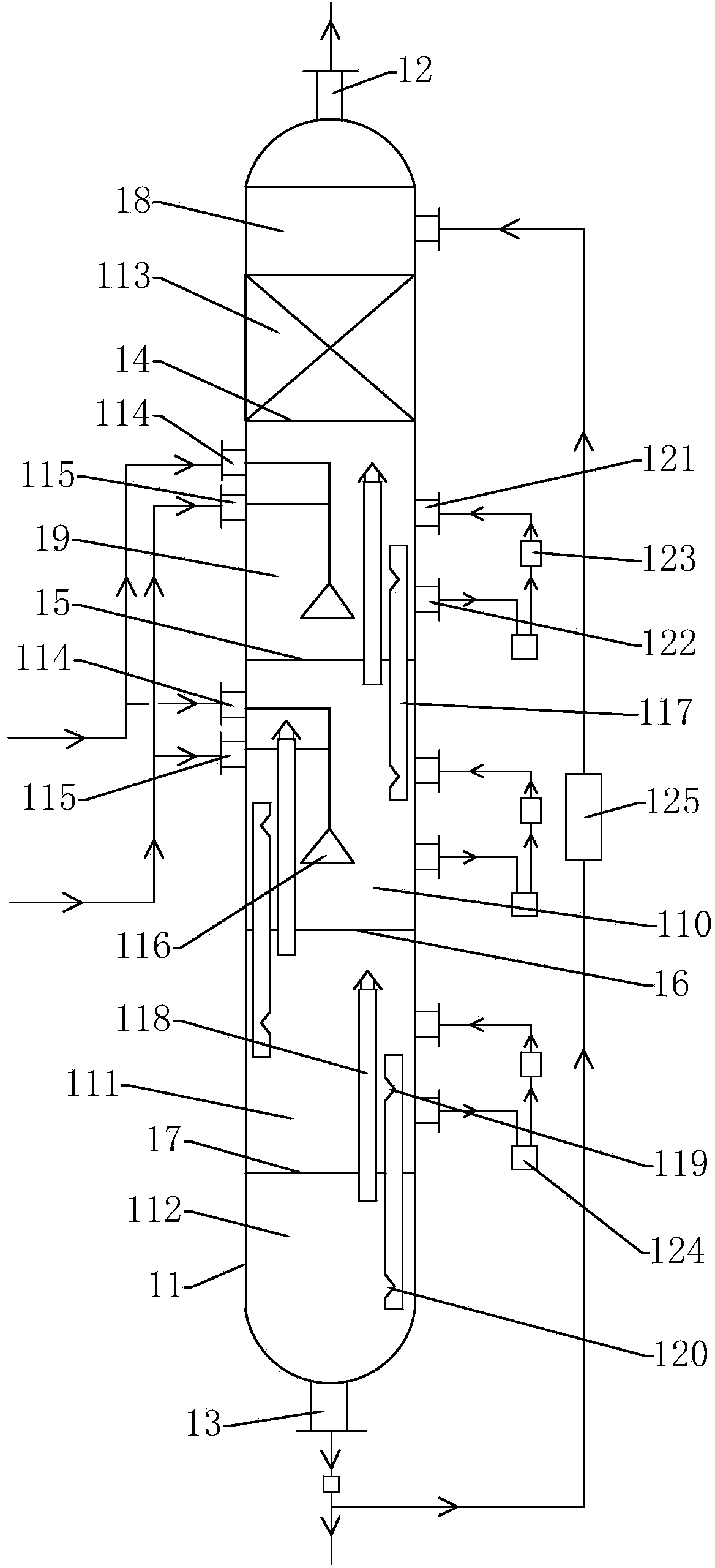

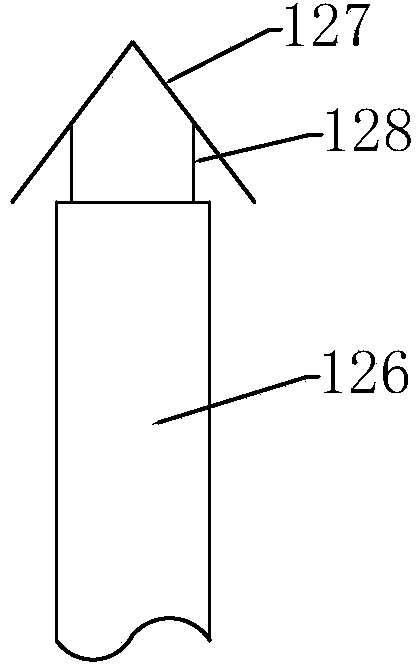

[0018] Such as Figure 1-Figure 3 Shown in, this embodiment comprises synthesis reaction tower 1, separation tower 2, dehydration tower 3 and rectification tower 4, the synthesis reaction tower material inlet 129 in the middle part of synthesis reaction tower 1 is communicated with material source by pipeline, the bottom Synthetic reaction tower material outlet 13 is communicated with the separation tower first inlet 21 of separation tower 2 middle parts through pipeline through material pump, is provided with a separation tower first bottom outlet 26 at the bottom of separation tower 2, separation tower 2 tops The top discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com